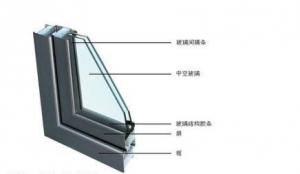

A variety of colors of insulating glass 5+12A+5

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

we introduced the advanced production lines (with automatic coating removing, automatic sealing system) and equipped with reverse osmosis deionized water preparation and storage equipment, automatic aluminum spacer bending equipment, low-e glass coating removing equipment, which is able to produce all kinds of specifications of insulating glass for customers. The production lines that are equipped with automatic vertical sealing system, abandon the disadvantages of traditional horizontal sealing (there will be no patch phenomenon), make the processed insulating glass more flat and smooth..

Insulating glass size specifications:

Maximum processing size: 2440 mm * 3500mm

Minimum processing size: 200 mm * 200 mm

Aluminum spacer specifics: 6 mm, 9 mm, 12 mm, 16 mm

Glass thickness: 3 mm to 19 mm

Insulating Glazing

A. All glass can be processed before assembly

B. Glass transfer onto the glass loading machine

C. Edge coating removing of coated glass

D. Wash and clean strictly

E. Automatic bending for air spacer

F. Automatic molecular sieve filling

G. Automatic butyl rubber applying

H. Automatic framing

K. Automatic scanning positioning

L. Automatic double sealing

M. Transfer by sucking disc

N. Conner finishing

O. Glass on the shelves till solidification

P. Customized wooden cases according to the size of glass

Q. Transfer the glass into the specific wooden cases

R. Leading Time:10 days for an average area of 1000 square

meters tempered glass

S. Trade terms: FOB and CIF.

T. Payment Terms: By TT, 30% deposit to start producing,

full amount balance paid before delivery.

U. The container loading after the package checking

- Q:I would like to build my own, customized aquarium and I have recently found out that float glass would be the best glass to use for it.I want the tank to be pretty long, considering i am turning it into a vivarium for my turtle.I need to know how much it will cost me to buy the sheets of float glass? or If I can just use regular glass for this instead?I am looking for something inexpensive, but with the quality also.thanks for the help :)

- Either glass is going to be very expensive. Check with your local hardware store.

- Q:Steel structure laminated glass is what material is what steel what glass

- Laminated glass, that is, between the two pieces of glass into a layer of polyvinyl butyral as the main component of the PVB interlayer. Even if the glass fragmentation, debris will be sticky on the film, broken glass surface remains clean and smooth. This effectively prevents debris from tying and penetrating the occurrence of falling events, ensuring personal safety.

- Q:China insulation film which company is better? Is it really effective?

- Must have some, after the home posted at noon obviously did not feel so hot, is the China Wu Zhuo glass film company posted

- Q:What is the difference between domestic glass and car glass?

- Home glass and automotive glass from the production process that is certainly not the same, this is nonsense ~~~~ The corresponding national standards are not the same, relatively speaking, automotive glass standards than the standard requirements of a lot of home. But in China they belong to the scope of architectural glass ~ ~ ~ Specifically want to know which is not the same?

- Q:Lanzhou Huazhong hollow glass factory where

- Lanzhou flat glass factory No.81, Xigu East Road, Xigu District, Lanzhou City, Gansu Province

- Q:Alright, so I want to build an under seat sub woofer enclosure for my smaller sports coupe. There's not much room at all under the seats, so I was thinking about going with a Pioneer 8" shallow mount sub, but the box is causing me a bit of a headache. I haven't had a chance to take a measuring tape to it, and doing so would be difficult.My idea is to get a can of the spray foam stuff used to seal homes, to inflate a garbage bag under the seat. After letting it sit and dry for a while, I'll remove the seat, pull the bag out with the exact dimensions of my seat and then play from there. I'll take the bag off of the foam and probably sand it down from there to fit my needs. I'll then use fiber glass to build up the box from the foam mold.Any thoughts on better ways to do this?PS: The car is a 2000 Mercury Cougar incase anyone has actual dimensions.

- you can take the seat out and then use a think foil paper and line under the seat then put a thin layer of fiber glass then let it dry and go from there also. * remember when your using the fiberglass your also gonna want to put a layer of bondo to strengthen the box but you do have a good idea also what ever works.

- Q:I am running a small business in building glasses, planning to find some cheap suppliers in China.

- I think the biggest and most infulential exhibition for construction is Fenestration China. the second should be Guangzhou Aluminum Window Door and Facade Expo.

- Q:Is the glass shading coefficient the shading coefficient?

- No. The shading coefficient on the 2680-1994 can be understood as "the shading coefficient of the glass", and the so-called shading coefficient is divided into "integrated shading coefficient", "shading coefficient of glass" and "shading coefficient of outer shading measures", the first Equal to the last two products.

- Q:Glass quality standards

- Glass sub-kiln and small kiln of the sub-kiln is the float glass. Float glass thickness uniformity, transparency is good, through the glass to see things will not be deformed, high quality. Small kiln glass: thin uneven, through the glass to see things deformation, the quality of the times. Glass thickness: from 2 mm to 2 to 20 mm.

- Q:Is the price of insulated glass foil?

- Building glass insulation explosion-proof membrane .85 yuan / square. With construction costs. Heat insulation rate of 80%, life of 10 years. Family-specific sun type.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

A variety of colors of insulating glass 5+12A+5

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords