A Light Weight Lightgage Steel Joist For Ceiling

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Specifications

Lightgage Steel Joist

1.Material: Galvanized Steel

2.Accept Customization

3.Free Sample Offer

4.Promptly delivery

Lightgage Steel Joist

2,Details

1) Material: galvanized steel

2) Zinc coating: from 100~275g per square meter

3) Yield strength 400mpa.

purlin and wall beam of steel structure building

The C-shaped purlins have excellent anti-bending property and are easy to install. They are widely used as the supporter of roof and wall in large-scale and mid-scale construction, such as factory, warehouse, garage, exhibition center, cinema, theatre, garden and so on.

Advantage:

(1). Design according to customers’ requirements

(2). Manufacture under complete quality control system---ISO9001

(3). Installation with instruction of experienced engineers

(4). Easy to assemble and dismantle

(5). Eco-friendly material: can be used for several times and can be recycled

(6). Shorter construction period, longer using time

(7). High strength and stiffness, high weight bearing.

3.Image

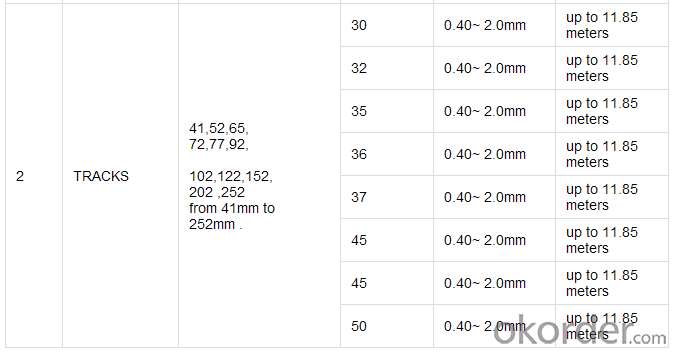

4.Detailed Specification

5.FAQ

1) Light steel structure

2) Color steel sandwich panel(EPS) panel for roof and wall

3) Color steel sandwich panel has a good fire proof and heat insulation

performance for the characteristic of the color steel sheet and polystyrene material.

4) The material of doors and windows are plastic steel

5) Easy to assemble and disassemble for several times without damage

6) Cost saving and transportation convenient

7) Anti-rust and normally more than 10 years using life

8) The house resistance to typhoon of force 12 degree, resistance to earthquake of force 7 degree

- Q:Light steel keel ceiling cracks how to deal with

- There are many reasons for the cracking of the roof, and the repair of cracks caused by different causes is not the same. Therefore, after the cracks, the first should be how the cracks are generated, to identify the problem of pipe fittings, and then develop a rest plan, should not blindly construction. Otherwise it may fall into a crack, make up the vicious cycle of the process. There are three main reasons and treatment methods: 1, the surface of the paint surface cracking repair If only the ceiling film to generate linear, multi-angle or irregular cracks, then the problem is not very serious. The reason may be due to a brushing too thick or dry re-coated, the substrate is too loose or rough, primer and paint is not matched and so on. Repair measures: to eliminate the affected film; to ensure that the film is not a very thick construction; to ensure that the front paint dry after re-coating; if necessary, with the appropriate primer to seal the substrate; for roughness of the substrate, The use of good flexibility of the product; substrate temperature below 5 ℃, not construction latex paint; primer and finish to match. 2, the temperature changes caused by the ceiling cracking If it is due to temperature changes caused by cracking, generally appear in the surface, will not affect the safety of the ceiling, the surface can be processed about. 1, the gap is not: If the surface gap is not large, it is recommended in the gap posted a layer of kraft paper, and then brush the surface coating. 2, the gap is wide: If the surface gap is wide, then it is best to cut out a piece of gypsum board, polished into the appropriate shape, fill in the gap, and then brush the finish paint. 3, improper construction caused by the ceiling cracking if it is because the ceiling frame, gypsum board finishes, etc. ...

- Q:What kind of material is better for some kind of ceiling, such as wood keel, light steel keel, or

- After the line with the woodworking board to open about 200mm wide oval frame (upper and lower layers) and then use 200 * 400 (height) of the wood plate around the oval to do the upper and lower layers of the two oval connected inside and then sealed 5mm board plate Hang up to shape out (drawing very good description of the painting really can not say you do not know clearly)

- Q:Light steel keel and wood keel the difference

- Light steel keel advantage is not easy to deformation, the disadvantage is to do modeling difficult; The advantages of wood keel is easy to do all kinds of modeling, the shortcomings are easy to crack. Top construction method, classification, comparison: Wood keel ceiling: Wood keel is easier to do local shape, keel brush fire paint twice, keel with nails or nail fixed, each with two nails fixed, made 300 * 300 or 400 * 400 frame, Adjust the low, straight, after the acceptance of gypsum board, the use of self-tapping fixed, self-tapping density: 20cm, the edge part of the density should be some. Wood keel and light keel combination: Do not recommend this practice, the individual feel better than the complete wooden keel or completely light keel production of strong. And the construction time is relatively troublesome. Completely use light keel: Light steel keel is not easy to do local shape, the use of expansion screws, d nails, etc., to install more solid. Light Gang keel with fire, not easy to deformation, strong and so on, is currently widely used method. Whether it is a large area of ??the ceiling or local ceiling can use this method of construction. Ceiling Note: Top, the keel of the wall should be fixed with a wooden wedge, nail, or with an expansion bolt. Do not use spikes (easy to fall). When the gypsum board is installed, the gypsum board seams are staggered from the keel frame. Fixed gypsum board: the use of self-tapping fixed, do not agree with the use of spikes (nail many, small, easy to brush anti-rust paint).

- Q:Please give valid certificate, thank you! The

- The keel of the ceiling needs to be re-examined: Detection parameters Keel: size deviation, mechanical properties; Accessories: size deviation, mechanical properties. Keel ceiling project quality acceptance project: Ceiling elevation, size, from the arch and shape should meet the design requirements. Test method: observation; scale inspection. The material, variety, specifications, regiment and color of the facing material should meet the design requirements. When the facing material is a glass plate, use safety glass or take reliable safety measures. Inspection method: observation; check product certificate of competency, performance testing report and admission inspection records. Finishes should be tightly installed. The overlapping width of the facing material and the keel should be greater than two-thirds of the width of the keel. Test method: observation; hand pull check; scale check. Boom, keel material, specifications, installation spacing and connection should meet the design requirements. Metal boom, keel should be surface corrosion treatment; wood keel should be anti-corrosion, fire treatment. Inspection methods: observation; foot check; check product certificate of competency, admission acceptance records and hidden engineering acceptance records.

- Q:Light steel keel ceiling good or wood keel good? Residential. I want to use light steel keel, but the designer said the reasons for modeling, light steel

- Now the basic use of keel less we do are to use light keel to do

- Q:Tectonic hierarchy of light steel keel

- Operating conditions 1. Construction of the structure should be in the cast-in-place concrete floor or prefabricated concrete floor slab, according to the requirements of the radio, according to the embedded φ6 ~ φ10 reinforced mixed boom, shot without the requirements of the arrangement of large keel location embedded steel hanging Rod, the general spacing of why 900 ~ 1200mm. 2. When the wall of the ceiling room for the brick masonry, the elevation should be in the ceiling along the walls and columns around the masonry embedded wood preservative, along the wall spacing 900 ~ 1200mm, the column should not be buried on each side More than two pieces of wood. 3. Install the roof of the various pipelines and ventilation ducts, to determine the light, ventilation and a variety of exposed mouth position. 4. All kinds of materials all ready to prepare. 5. Ceiling cover panel should be installed before the wall, wet operation project. 6. Take the roof construction platform. 7. Light steel skeleton roof in a large area before the construction, should do the model between the roof of the crown, lamp, vents of the tectonic treatment, block and fixed methods should be tested and approved by the approved before the big Area construction.

- Q:Light steel keel ceiling which brand is better

- You can go to the forum to consult the other owners to see everyone's views

- Q:Light steel keel ceiling do anti-support angle iron how fixed on the main keel, how fixed on the ceiling surface?

- Ceiling on the anti-supporting material, you can use metal (such as angle iron), you can also use a small piece of wood, but this depends on the supervision requirements, in principle, can not use wood materials, but sometimes as long as the supervision does not speak, With wood materials can be, but the fire paint or to brush.

- Q:What is the general ceiling of indoor ceiling?

- Upstairs copy of the good. Really quite detailed. That I also talk about it. Light steel keel wood keel aluminum buckle plate steel plate plaster board sauna board

- Q:Light steel keel ceiling construction some of my hair

- The best on the network to find it

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

A Light Weight Lightgage Steel Joist For Ceiling

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords