9w EPISTAR Chip LED Candle Lamp,Warm & Neutral White,

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

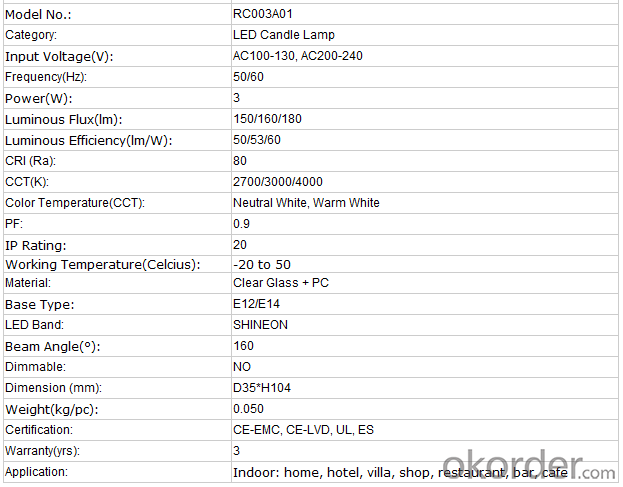

1. Technique Specifications

2. Our bulbs Advantages:

1).Beautiful shape with silver line

2).Silver and white colors optional

3).Dia-casting aluminum, good heat dissipation

3).Wide voltage AC100-240V

4).Constant current driver

5).Qualified with CE & ROSH

6).Great prices for big materails purchase

7).Private mold for we have our own injection molding factory

3. Feature

1). Using ultra-bright highest level Epistar LED chips with proprietary encapsulation technology, realizing excellent luminance, low brightness decline;

2). Constant-current driver is used to ensure the lamp working with reliability and stability.

3). Scientifically-designed heat dissipater with much better cooling effect;

3). Great energy-saving effect, save energy by over 70% comparing with traditional lamps;

4). Lamp surface treated with anodization, corrosion-resistant, artistic appearance.

5). Long lighting distance and wide lighting areas

Cautions:

1. Switch off the power before replacing the lamp.

2. Keep away from direct sunshine and high temperature.

3. Indoor use only.

4. If any doubt about the installation or use of this product, consult a competent electrician

- Q:LED bulb w can replace 40W incandescent lamp

- D lamp lumen value is ordinary incandescent lamp about 3 times, but LED ball bubble mask transmittance should be based on material, can use 10W or so LED acrylic mask ball bubble instead. Because I received a similar customer complaint, 7W's LED light bulb was replaced with an 20W energy-saving lamp, which was not bright enough.

- Q:Seeking the production process of LED bulb... Thanks

- First of all, of course, the preparation of materials, the specific operation of the lamp to practice, each lamp has different methods of assembly, there are different work instructions. Only through practice can we write good and practical processes. Figure is a flow chart of MR16 assembly.

- Q:What's the reason for the LED bulb strobe?

- Currently on the market with single stage PFC driver circuit, there will be strobe, causing the flash because the ripple is too large. Single stage pFC circuits are not possible

- Q:LED what is the plastic shell of the bulb? What plastic material is better? What do you need to pay attention to?

- LED is the most important heat, light will not be so serious, the thermal conductivity is relatively high Aluminum Alloy, so LED manufacturers usually choose to use aluminum shell

- Q:LED what is the glue between the aluminum base of the bulb and the cooling aluminum?

- It is best not to direct contact with glue, glue because the thermal conductivity of aluminum than a lot of difference, even a thin layer will reduce the heat out of the speed of the screw can be used to aluminum plate and aluminum fastening together, the contact surface is smooth, when necessary, can use some conductive silicone grease amount

- Q:60W how many lumens and how many W LED bulb does incandescent bulb replace?

- General household enough, if in 10 square meters of housing, installation of more than 10W LED lights, brightness is too good, if not the study, it is best not to.

- Q:What's the difference between a glass cap for a bulb and a PC hood?

- ProcessabilityMachinable, blister, special-shaped processing PC easier.

- Q:LED how does the bulb return electricity?

- A 0 ohm resistor with a large point on the negative electrode

- Q:What advantages does LED bulb replace energy saving lamp?

- LED lamp structure is strong, green environmental protection, not easy to destroy, long life (generally 5 years is not a problem), this is energy-saving lamps can not be compared

- Q:What are the requirements of the LED series inspection specification for bulb bulbs?

- Anti torque test is carried out using only suitable for torque meter, torque test, lamp holder should be firmly bonded on the lamp or lamps used to purchase spin spin out parts, E26 and E27 for 3N*m.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

9w EPISTAR Chip LED Candle Lamp,Warm & Neutral White,

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords