99% Al2O3 Corundum Brick Used in Linings of Ovens of Petrochemical

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Corundum Bricks

CMAX corundum bricks use compact electro-smelted corundum and alumina powder as main raw materials, shaped under high pressure after machine-blending and fired at high temperature.

Application of Corundum Bricks

Corundum Bricks can be used nearly all fields of industrial application where extreme high temperature and increased resistance against aggressive slags and atmospheres. Such properties or features of Corundum Bricks are necessary especially in the chemical industry and for the production of carbon black. The addition of chromium oxide, zirconium oxide and phosphates lends the bricks excellent structural flexibility, which is required for ash melting furnaces and gas reactors in incinerators.

Image of Corundum Bricks

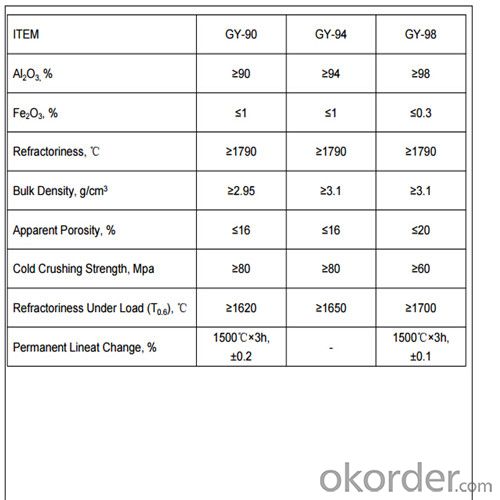

Technical Data of Corundum Bricks

Why Choose Us

l We are a government owned company with ISO certificate.

l We are listed in Global Fortune 500 with D & B report.

l We have more than 11 refractory production facilities and bases across China. We have a wide products range, such as ceramic fiber products (ceramic fiber blanket, module, board, paper, bulk), ceramic fiber textile (ceramic fiber rope, cloth, tape, yarn) etc, refractory brick (fireclay brick, high alumina brick, silica brick, magnesia brick etc), monolithic refractory materials, insulating fire brick, calcium silicate board, mica sheet, steel fiber. You can find various products here, and we can combine the light weight ceramic fiber products with the heavy weight refractory brick in one container delivery, then save the sea freight for you.

l We have strict materials selecting system and quality control system. We have the ability to take responsibility for your orders and product quality.

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervis

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such us U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q:What refractory materials are adopted in each part of the blast furnace?

- The lower part of the shaft due to high temperature and dust by scouring and alkali metal vapor erosion, so the requirements for the slag resistance, alkali resistance and high temperature resistance, wear resistance of high quality clay brick, high alumina brick, carborundum brick or corundum brick. Belly temperature reaches 1400~1600, and slag, steam erosion, erosion and corrosion is strong, therefore, the silicon carbide reaction bonded silicon carbide brick.

- Q:What's the size of the fused zirconia corundum refractories for glass furnace? What are the main kilns? How much is the dosage?

- The fused zirconia corundum brick is made up of 30% ~ 41% zirconia two in the alumina burden. The main mineral compositions are corundum, zircon and glass phase. The main varieties are fused (or cast) zirconium corundum brick (also known as AZS casting brick) and sintered zirconia corundum brick. Generally speaking, zircon corundum brick means sintered zirconia corundum brick. It is made from alpha -Al2O3, partially stabilized zirconia and zircon corundum clinker, which is prepared by proportioning and molding at 1700~1750 DEG C and then sintered at two. The sintered zirconium corundum brick has a strong resistance to molten glass, and its thermal shock resistance is stronger than that of fused zirconia corundum brick. It is mainly used as lining of glass furnace and induction furnace, as well as steel rolling furnace, slide rail, etc..

- Q:Is liquid phosphoric acid two aluminum hydrogen flammable?

- Two aluminum liquid hydrogen phosphate using spray paint, cement, refractory castable and binder for foundry industry, mainly used in refractory industry corundum, chromium corundum nozzle coal water slurry gasifier with chromium aluminum zirconium corundum brick production.

- Q:Which is good, glazed brick and whole cast glazed brick?

- These two tiles have their respective advantages and disadvantages, in fact, to say which kind of good, mainly depends on the decoration of personal preferences and the location of the shop. If it is only the shop wall, then design and pattern rich whole glazed tile is good, it can make the room impressive, improve decorative effect, make the decoration style to fit the characteristics of his personality. In addition, clean up is relatively easy, not easy to contaminated with oil stains and other pollutants. If you are laying tile, suggested the use of tiles, tiles of good antiskid effect, water absorption rate is relatively low, so the kitchen toilet bathroom and other wet places is not easy to water seepage, improve the convenience of life.

- Q:How much is a refractory brick?

- This question is too general, refractory bricks according to the use of the environment and industry, there are a variety of materials, a variety of specifications, prices vary greatly.

- Q:What are the refractory materials?

- Acid refractory with silicon oxide as the main component, are commonly used in brick and clay brick. Silica is silica containing more than 93% silica products, raw materials used in silica, silica and other waste, the acid resistance of slag erosion ability, high load softening temperature, volume shrinkage after repeated burning, or even a slight expansion; but it is vulnerable to the erosion of basic slag, low thermal shock resistance. The brick is mainly used for thermal equipment of glass furnace, coke oven, acid furnace etc.. Clay brick with refractory clay as the main raw material, containing 30% to 46% of alumina, weak acid refractory material, heat shock resistance, resistance to acid slag, widely used.

- Q:What does refractory consist of?

- Refractory materials can be divided into main raw materials and auxiliary raw materials according to their function in the production process of refractory materials.The main raw material is the main body of refractory. Auxiliary raw materials can be divided into binders and additives. The role of bonding agent is to make the refractory body in the production and use process has enough strength. There are commonly used lignin, phenolic resin, asphalt, cement, water glass, phosphoric acid and phosphate, sulfate, some main raw material itself has the effect of binder, such as clay; additive is to improve the production of refractory materials and construction technology, or strengthen the refractory material of some properties, such as stabilizer, water reducing agent, inhibitor, plasticizer, foaming agent, dispersing agent, bulking agent, antioxidant.

- Q:Ask for help about the phase of refractory material

- Major crystalline phase. The main crystalline phase is a crystalline phase that constitutes the principal part of the material structure and has a high melting point and a dominant role in the properties of the material. The properties, quantities, distribution and bonding state of the main crystalline phases of refractory determine the properties of the products directly. A lot of refractory products, such as mullite brick, corundum brick, magnesia brick, magnesia spinel brick, silicon carbide refractory products, etc., are the main phase named.

- Q:What are the advantages of refractories?

- Acid refractory material usually refers to refractories with SiO2 content greater than 93%. Its main characteristic is that it can resist acid slag corrosion at high temperature, but it is easy to react with alkaline slag.

- Q:What refractory materials are used in industrial furnaces?

- Masonry parts using his cooperation because of the repair or overhaul time, labor, materials, fuel consumption is great. Some of the other, a stove overhaul, will inevitably affect the other parts of life. Therefore, the selection of materials should be thinking of various parts of masonry of life, the habit.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

99% Al2O3 Corundum Brick Used in Linings of Ovens of Petrochemical

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords