97 Silicon Carbide90/Recrystallized Silicon Carbide/SIC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

97 Silicon Carbide90/Recrystallized Silicon Carbide/SIC

1.Structure of Silicon Carbide Description

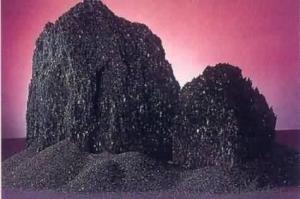

Black Silicon Carbide is produced with high temperature in a electric resistant furnace from a mixture of quartz sand and petroleum coke.

Black silicon carbide is typically used for working on cast iron ,non-ferrous metals, stone, leather, rubber, and other materials which requires sharp cutting characteristics. The mineral is also used widely as a refractory material and metallurgical additive.

2.Main Features of the Calcined Bauxite

Its hardness is between that of fused alumina and synthetic diamond and mechancial intensity of it is also greater than that of fused alumina. It is brittle and very sharp and has a certain degree of electrical and heat conductivity.

3.Main usage of the Calcined Bauxite

1.Grinding non-ferrous materials, rock, stone, leather, rubber, finishing tough and hard materials

2.Bonded abrasive tools, lapping and polishing

3.Widely used as a metallurgical additive and refractory material

4.Refractory

4. Calcined Bauxite Images

5. Calcined Bauxite Specification

Specifiction | SiC | F.C | Fe2O3 | Moisture |

SiC 86 | 86%min | 2.4%max | 2.0%max | 0.2%max |

SiC 88 | 88%min | 2.3%max | 2.0%max | 0.2%max |

SiC 90 | 90%min | 2.0%max | 1.8%max | 0.2%max |

SiC 92 | 92%min | 1.8%max | 1.7%max | 0.2%max |

SiC 93 | 93%min | 1.8%max | 1.6%max | 0.2%max |

SiC 95 | 95%min | 1.0%max | 1.3%max | 0.2%max |

SiC 97 | 97%min | 0.8%max | 1.2%max | 0.2%max |

SiC 97.5 | 97.5%min | 0.8%max | 0.9%max | 0.2%max |

SiC 98 | 98%min | 0.5%max | 0.5%max | 0.2%max |

6.FAQ of Calcined Bauxite

1). Q: Are you a factory or trading company?

A: We are a factory.

2). Q: Where is your factory located? How can I visit there?

A: Our factory is located in Ningxia, China. You are warmly welcomed to visit us!

3). Q: How can I get some samples?

A: Please contact me for samples

- Q:What are the main components of refractory cement?

- Refractory cement, also known as aluminate cement, can also be gray. Aluminate cement is often yellow or brown. Aluminate cement takes bauxite and limestone as raw materials, alumina content of about 50% as the clinker. And it is a hydraulic cementing material made by grinding. The main mineral of aluminate cement is mono calcium aluminate (CaO · Al2O3, abbreviated CA) and other aluminates, and a small amount of dicalcium silicate (2CaO · SiO2), etc.

- Q:Which refractory is better for building 1500 degree kiln ?

- High alumina brick or 99 alumina hollow ball brick is OK, which can withstand a temperature of 1600 ℃.

- Q:Classification of porosities in refractories and their effects on properties

- The first two types of stomata are commonly examined, known as apparent porosity.

- Q:How much is the duration of fire resistance of the porous brick shale?

- It depends on its formula since the highest temperature varies from formula. For example, the temperature of common bricks is 900℃, if the lime in it accounts for most part, then the temperature could reach 1050℃; if coal ash accounts for over 40%--50%, then the temperature could amount 1050℃--1150℃, I hope my answer will help you a lot.

- Q:What advantage and disadvantages it has compared to common fire insulation materials

- Advantage and disadvantages of A-level heat perserving materials of equal effectiveness 1, the component materials of A level thermal insulation materials are inorganic materials, so it is high temperature resistant, non-combustible, fire-resistant; 2, good durability, aging resisitant, and having the same service life as buildings; 3, a level thermal insulation material can be well combined without using polymeride to bond, coat mortar, reinforced net, needing only few construction procedures. It is anti seepage with few quality problems; 4, absorb few water, and can bond firmly with the cement mortar, tile adhesive tile, safe and reliable; 5, a level thermal insulation material have the same service life as buildings, without the need to increase the cost on maintenance and renovation during its life span, and can maximize resource conservation.

- Q:Refractory materials are needed for casting metallurgy.

- Refractory material used in foundry work is that refractories for cupola furnace? Cupola is a high temperature furnace which is used for melting molten iron, and refractory material adopted is mainly low iron high grade clay brick and clay lightweight insulation bricks, etc.foundry ingot refractory material is pearl sand (also known as pearl jewelry sand, fused ceramic, ceramic sand) it is made of high quality bauxite material by arc melting furnace.

- Q:Is there requirement for radiation indicator in refractory?

- All refractories have no radiated harm to environment, so there is no requirement. From the elemental analysis, magnesite. I do not know it is helpful to you. But for refractory rwa material, any chemical element is radiated, including silicon?dioxide; If they are radioactive. From the use analysis, such as bauxite, do not have use value.

- Q:Which one is the best refractory material?

- Resin bonded refractory is mainly abot aluminum magnesium carbon, and carbonaceous etc. Thermoplastic resins need to add the coagulant (Uto), ageing mixture for a period of time, so the production cycle is long. Hot hard resin is relatively not so complex, but it’s not as good as thermoplastic resins in thermoplastic binding.

- Q:What is the requirement of refractory concrete for raw materials? What is the main principle of commercial mixing station?

- Refractory concrete generally divided into three categories: lightweight concrete (used in insulation); refractory concrete (for refractory temperature requirements are not very high position, and can withstand a certain air scour); heavy refractory concrete (flow with higher requirements for refractory temperature parts, and can withstand a certain intensity). Mainly depends on the design temperature and the use of parts.

- Q:What kind of materials are needed to make refractory bricks?

- Refractory materials generally refer to inorganic non-metallic materials with fire resistance above 1580℃. It plays an important role in metallurgy, nonferrous metals, chemical engineering, ceramics, and industrial production. Different industry needs different materials. You can turn to the knowledgeable internet.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

97 Silicon Carbide90/Recrystallized Silicon Carbide/SIC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords