86% Rotary Kiln Alumina Calcined Bauxite Refractory Raw Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

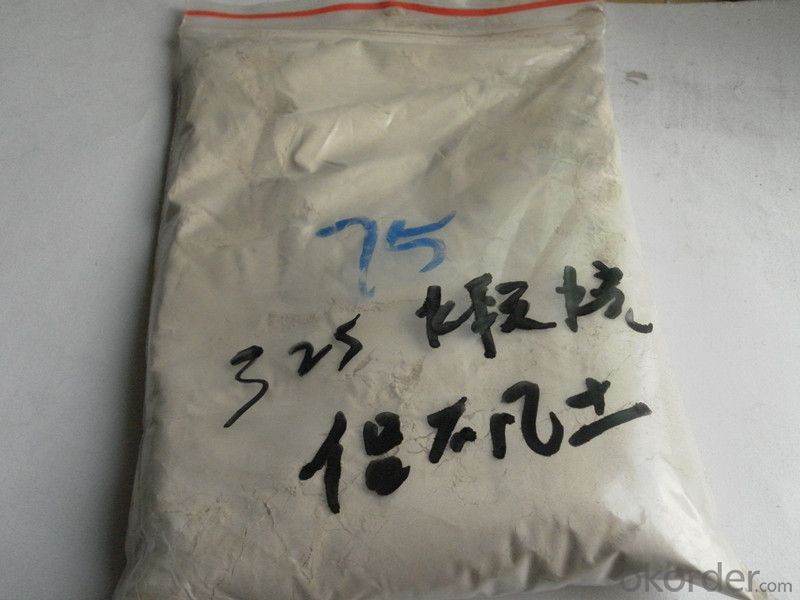

86% Rotary Kiln Alumina Calcined Bauxite Refractory Raw Material

Specifications

1. We directly supply calcined bauxite

2. Al2O3:70%/75%/80%/85%/86%/88%/90%

3. Size:0-1-3-5-8-10/200mesh/325mesh/400mesh/500mesh

Size:

Lumps /Grains:0-1mm,1-3mm,3-5mm,5-8mm /Powders:100mesh, 200mesh,325mesh

Product Description:

Bauxite, alumina or bauxite miner , main ingredients are aluminum oxide, hydrate alumina containing impurities,

is an earthy mineral.White or grey, brown yellow or light red by iron.From 4 to 3.9 g/cm3 density, hardness, 1 ~ 3, opaque, very brittle.

Very difficult to melt.Insoluble in water, soluble in sulfuric acid, sodium hydroxide solution.Mainly used for aluminium, refractory material.

Calcined Bauxite Grade:

Shaft Kiln Bauxite

Rotarty Kiln Bauxite

Round Kiln Bauxite

Packaging & Delivery

Packaging Details: In bulk or in 1-1.25mr bag

Product Pictures:

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q:Which refractory is suitable for the tunnel kiln?

- Shuttle kiln refractories requires the good thermal shock properties. Because the tunnel kiln is continuous firing furnace, the temperature in the kiln is long time stable and with little fluctuation. The shuttle kiln is intermittent kiln firing. The temperature in the firing kiln is adjusted by the firing curve. It is with a relatively short time and serious fluctuation. The seal and kiln car take use of the heavy corundum brick. If it is continuous kiln, the alumina hollow ball bricks are used in the burning zone. The seal of the burning zone takes use of the kiln car brick and the seal takes use of the heavy corundum brick.

- Q:Which brand of refractory fiber hard thermal insulation board is better?

- One colleague said Huayou refractory fiber hard thermal insulation board is good. The size (mm): 600*400*60. refractory temperature: 1770 ~ 2000 ℃ (℃), and the price is 2850 yuan a ton.

- Q:Would you like to know if there are any enterprises in Mianyang that need fire-resistant materials?

- Many enterprises need refractory materials. You can go to Mianyang large private enterprises to askSupermarkets, stations, hotels are required

- Q:What is high alumina refractory?

- It refers to inorganic non-metallic material with refractoriness of higher than 1580℃. Refractoriness refers to the celsius temperature that the cone-shaped refractory sample without load can resist, and under which the sample won't soften and melt down. Refractory material appears together with high temperature technology, and roughly dates from the Middle Bronze age. In the Eastern Han Dynasty (AD25~AD220) of China, fireclay refractories has been used as furnace refractories and saggers for making porcelains. In the early 20th century, refractory material develops toward the direction of high purity, high dense and ultra high temperature products, and meanwhile unshaped refractory and refractory fiber with no need of firing at all and with low energy consumption appear.

- Q:Who knows about the fire endurance of A grade fireproofing glass doors?

- Fire doors and windows are divided into grade A, B and C according to the real national situation, also the minimum fire endurance has been stipulated, namely, the minimum fire endurance of grade A is 1.50 h, that of grade B and C are 1.00 h and 0.50 h respectively. There are wooden fire doors and steel fire doors. The main purpose of it is to reach the time that fire resistance should last. But door?closers are required to install. The fire endurance of A grade wooden fire doors should be no less than 90 min, and that of B grade fire doors should be no less than 60 min, that of C grade fire doors should be no less than 30 min! ! !

- Q:Does anyone know the fire endurance of steel stud partition?

- The fire endurance degree is 1 hour. which is in line with the national building material fireproofing test standards. CaSo4.2H2O is molecular gypsum molecular structure formula, containing 20% ??water, crystal water and free water, when putting on fire, 10% of the surface water will slowly evaporate, remaining10% of crystal water. It is a class A fire retardant material itself. The longest time can be 4 hours.

- Q:How many kinds of refractory materials are there in the EI?

- I suggest that you contribute articles to foreign SCI journals for the odds are better, and generally the articles that fill the bill will not be rejected. The traditional refractory materials can contribute to EI journal. If being rejected by EI journal, you can also contribute to Russia's journal Industrial Ceramics and Refractories. I didn't contribute to the Journal of Wuhan University of Science and Technology, the receiving cycle is almost 3 to 4 months. Though the impact factor is low, domestic EI journal is not so good, it is still SCI journal. This is my own experience, please take my advice. The best journals are the Journal of the American Ceramic Society and the Journal of the European Ceramic Society, I heard that they are not bad. But the best domestic EI refractory material journal is the Journal of The Chinese Ceramic Society. It is very long, but if it belongs to your university, it is another pair of shoes. Journals now all want to have materials about functional ceramics, and they don't want Chinese articles, if your English is not well enough, you can choose Ceramics International and Japan Ceramics but they have strict manuscripts reviewing standards.

- Q:What is the importance of silicon powder in refractory processing?

- in amorphousness it is mainly the mobility

- Q:what's the application of fireproofing abs materials?

- a kind of ABS alloy shell, a toy of child, low load bearing, refrigerator lining, it can be processed into various wear-resisting sheets, plates,and has good electrical performance, it can be used as electronic components or auto parts, all kinds of insulation materials, it's easy to machining on the surface, so it can be made into designated special products (such as electroplate), and easy coloring, it can be processed into colorful products, also can be used as a fireproofing electrical appliance outer covering, adding alloy to it will improve its comprehensive performance, etc

- Q:I want to know what is the slim in the refractory bricks

- Where are you from, I can introduce to you

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

86% Rotary Kiln Alumina Calcined Bauxite Refractory Raw Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords