82% size 200mesh of Rotary Kiln Calcined Bauxite for High-Alumina Cement

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

82% size 200mesh of Rotary Kiln Calcined Bauxite for High-Alumina Cement

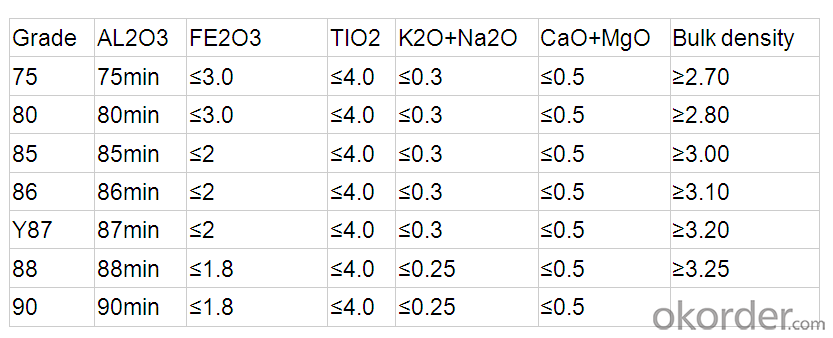

Specifications

1,Manufacturer-Direct sale

2,Good fireproof insulation

3,High bulk density

Calcined bauxite

Bauxite is earthy mineral which consists mainly of Al2O3 , a kind of hydrated alumina containing impurities. According to the usage, It can be divided into the levels of Metallurgy, chemical industry, grinding, cement, and refractory. Clinker is pale yellow and dark grey. It is mainly used for high aluminum refractory material, and also can be used to make the fused corundum. Our materials of calcined bauxite is mainly D-K Style Bauxite Ore.

Product Description:

Usage

(1) aluminium industry. Used in national defense, aerospace, automotive, electronics, chemical industry,

daily necessities, etc.

2 precision casting. Alumina clinker made after the mould precision casting processed into fine powder.

Used in military industry, aerospace, communications, instrumentation, machinery and medical equipment department.

(3) is used for refractory products. High bauxite clinker refractoriness is as high as 1780, chemical stability strong,

and good physical properties.

(4) aluminum silicate refractory fiber. With light weight, high temperature resistance, good thermal stability,

low thermal conductivity, heat capacity is small and the advantages of resistance to mechanical shock.

Used in iron and steel, nonferrous metallurgy, electronics, petroleum, chemical, aerospace, atomic energy,

defense and other industries.

(5) in magnesia and bauxite clinker as raw materials, add the appropriate binder,

used for pouring ladle whole ladle lining has particularly good effects.

(6) manufacture alumina cement, abrasive materials,

ceramic industry and chemical industry can be aluminum of various compounds

Product Pictures:

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q:What is the criterion of entry of refractory clay industry?

- Chemical composition of refractory clay is one of the important factors affecting its quality. Al2O3 is the beneficial part of refractory clay, and it mainly exists in aluminum hydroxide minerals (diaspore, boehmite, gibbsite), and it also exists in aluminosilicate minerals (kaolinite, illite montmorillonite, etc.). In general, the content of Al2O3 in soft and semi-soft clay is 30% to 45%, the hard clay is 35% to 50%, and high alumina clay 55% to 70%. Fe2O3 mainly exists in hematite, magnetite, goethite and siderite, and is the main harmful component of refractory clay. There is no evident law on the content of Fe2O3. The content in high alumina clay is 0.5% to 2.2%, hard clay is 0.5% to 2.5%, and the soft clay is generally 1.0% to 2.5%. K2O and Na2O are harmful impurities in refractory clay, which mainly exist in illite and mica and other minerals, and the content varies greatly. CaO and MgO, etc., although they are harmful impurities, but the content is generally small.

- Q:who knows the fire resistant level of fireproof gypsum board ?

- combustion performance of building decoration materials should be divided into four levels: A level, non-flammable; Class B1, flame retardant; B2 level, flammability; B3 level, flammable. Choose the materials above B1level. Thank you

- Q:What is the material composition of the new fire-resistant coating?

- New fire-resistant coating generally consists of base material, dispersion media, flame retardants, fillers, additives (plasticizers, stabilizers, waterproofing agents, moisture, etc.). (1) Base material is the basis of the composition of the coating, and it is the main film-forming substance, playing a decisive role in coating performance . For fire-resistant coating, its base material must be capable of matching with the flame retardant to constitute an organic fireproofing system. The base material commonly employed at home and abroad includes inorganic and organic film-forming material. Inorganic film-forming materials include silicate. Si03, K2 Si03Na2 Si03), silica and phosphate [Al. (HPO.). ] ect. There are a wide range of organic film-forming substance, usually flame retardent organic synthetic resins, such as phenolic resins, halogenated alkyd resins, polyester, halogenated olefin resins (such as vinyl chloride resin), amino resin (melamine resin, urea resin, etc. ), tar-based resins, furan resins, heterocyclic resins (e.g., polyamide-imide, polyimide, etc.), organic elements resins (e.g. silicone resin), rubber (halogenated rubber such as chlorinated natural rubber) and so on. There are numerous latex taking water as solvent. www.hc3600.

- Q:Which refractory material is better in China? Industrial furnace, mainly in non-ferrous industries, glass kiln, cement kiln business.

- Such solid nano microporous insulation material with nano inorganic refractory powder special, with a huge surface area, nano particles contact between the minimum point contact point contact thermal resistance is very large, the heat conduction effect of the material becomes very small, resulting in heat conduction coefficient of solid such nano porous insulation materials very small; nano pores formed of nanoparticles, the average size of 20 nm, and the average free path of molecular thermal motion at room temperature under static air is 60 nm, thus locking the air molecules in powder within nano pores, making the micro convection heat transfer effect between the stationary air molecules disappeared. The room temperature thermal conductivity of solid such nano microporous insulation material is lower than the static air; at high temperature, the main effect of heat transfer heat radiation, Good energy-saving insulation materials with nano microporous infrared additive special, stop at a high temperature and reflected infrared radiation, reduce the heat radiation effect to the lowest point, the radiation heat transfer coefficient of materials under high temperature is reduced to the lowest value.

- Q:Where is the production of refractory manganese alloy manufacturers? Manganese is recommended between 63 and 70!

- China is mainly used in honing, maybe I face all doubt you forget who may waste cheap no taste who cheated you don't mind set back easily stripped of a planet in the comfort of your brow you open your mouth and then grow the universe to my hand behind you let you spend what a fragile Oh maybe I face all abandoned about half past three in the morning wake up to drink a cup of soda rather baffling weary belch a bubble the tiny uneasy, and perhaps two of us Butterfly

- Q:What is the interior fireproof thermal insulation material?

- The methods of thermal insulation wall have three kinds of materials. First: gypsum board or cement board are stuck outside the polyphenyl board; second: lightweight brick build; third: infill polyphenyl board, lightweight brick is built outside. The first two has almost the same price. The latter is slightly expensive. 60 yuan / square meter is not very expensive!

- Q:What's meaning of CN of fire-resistant material?

- The commonly used preparation methodsinclude shock compression, high-pressure pyrolysis, ion implantation, reactive sputtering, plasma chemical vapor deposition, electrochemicaldeposition, ion beam sputtering, , low-energy ion radiation, pulsed arc discharge,pulsed laser inducing, etc. But the compounding result of superhard materialis not ideal due to deposition of amorphous CN film, nanometer level sizedC3N4 crystalline grain set in the amorphous film and few large graincrystal.

- Q:what's the standard of fireproofing material?

- first, the classification of fire resistant levels of buildings, 1, the classification basis of fire resistant levels of buildings, the classification of fire resistant levels of buildings is one of the basic building fire protection technology measures, our national architectural design specification divides fire resistant levels of buildings into first, second, third and fourth class, first class ios the highest and has the most strong fire-resistant capacity, fourth class is the lowest and has the weakest fire-resistant capacity. Fire resistant level of buildings depends on the combustion performance and fire endurance of the components of the buildings. construction components refer to the wall, base, beam, column, floor, stair, suspended ceiling and other basic components of buildings. Combustion performance and fire endurance of building components are shown in table 4-11), the combustion performance of building components are divided into non-combustible component,hard-comnustible component,combustible?component,according to their response to the fire. as for building components, non-combustible component includes wall column and base,etc; hard-comnustible component includes hanging?bracket, suspended ceiling and internal pipe;combustible?component includes doors and windows, suspended ceiling, decoration materials,etc.

- Q:How to divide the fire resistant level of construction thermal insulation materials?

- 1, Combustion performance of the national standard building materials are divided into the following levels: Class A: incombustible building material: Material that almost never burn. Class B1: nonflammable building material: Nonflammable materials have good effect of flame resistance. In case of fire it in the air or at high temperature it is difficult to catch fire and spread, and when the fire source is removed, the combustion can stop immediately. Class B2: combustible?building?material: Combustible materials have good effect of flame resistance. In case of open fire in the air or at high temperature, it will immediately burst into flames and spread the fire quickly, such as wooden column, timber roof truss, wooden stairs, etc. Class B3: flammable building material: No flame-retardant effect, highly flammable, high risk of fire. 2, According to fire?rating, external wall thermal insulation materials can be divided into 1) thermal insulation material with class A combustion performance. Rock wool, glass wool, foam glass, foamed ceramics, foam cement, hole-closed perlite,etc. 2) thermal insulation material with class B1 combustion performance: Extruded polystyrene board (XPS) after special treatment /polyurethane (PU) after special treatment , phenolic aldehyde, gelatine powder polyphenyl granule, etc. 3) thermal insulation material with class B2 combustion performance: Molding polystyrene board (EPS), extruded polystyrene board (XPS), polyurethane (PU), polyethylene (PE), etc.

- Q:What are first rate fire resistant window materials?

- Natural environmental protection, non-poisoned, non-peculiar smell, non-radioactive; non-combustible, fireproofing, moisture-proof, corrosion-resistant; easy construction, lightweight, high strength, www. jsxsmy.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

82% size 200mesh of Rotary Kiln Calcined Bauxite for High-Alumina Cement

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords