8011 Household Aluminium Foil for Baking Cooking

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Description of 8011 Household Aluminium Foil for Baking Cooking

1. Light weight, clean, thin, good flexibility and cushioning;

2. Invariable if it is attacked repeatedly;

3. Low thermal conductivity and superior heat insulation;

4. Outstanding safety and environmentally friendly;

5. Easy to install, high efficiency;

6. Cost effective and versatile.

2.Why you want to choose us?

We've been specialized in aluminium foil for more than ten years, we know this product very well, we know what is good, what is the market price.

3.Specification and Application of 8011 Household Aluminium Foil for Baking Cooking

1) Alloy 8011, 1100, 1235

2) Thickness: 0.009-0.02mm

3) Temper: O

3) Width Size: 200mm-1200mm

4) Customer's specification is available

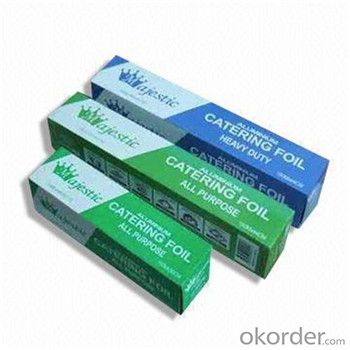

4.Pictures:

5.FAQ:

1) What is your delivery time?

Our regular production time is over 30 days, It depends on the order quantity also.

2) What is your payment term?

We accept T/T, LC at sight, Usance LC 30, 60, 90, 120, 180 DAYS.

3) What is your price structure?

Our foil price is based on Shanghai Metal Price(SMM), not LME, but we could offer LME+ Conversion for your reference.

4) What is your Delivery term?

We do FOB, CFR, CIF, we don't do DDP.

5) Could you offer sample?

We could offer sample as your requirement. A4 Size sample is free for you, for bigger roll sample, it depends on the coil weight.

- Q:What coolant does the aluminum bar drill with?

- It has the characteristics of stable emulsion, no peculiar smell and long service life. It is suitable for data machine tools, CNC lathes and CNC machining centers.

- Q:Can the iron core of an electromagnet be replaced by a steel bar and an aluminum bar?

- Steel bar, aluminum rod not. There are three kinds of magnetic materials composed of elemental chemical elements, namely iron cobalt nickel three kinds of metal, they can only have magnetism, this property is a natural one, with its atomic structure, metal is not other. Steel bar is the main component of iron, so it can be.

- Q:How high is the aluminum bar heated until it is bent?

- Look at this change: a hub is a kind of precision forging, precision forging, aluminum bar heating by high-end technology of spinning and heat treatment and NC machining, and then after the product inspection process to eliminate defects strictly, finally produce high quality precision forging Aluminum Alloy hub.

- Q:What brand of easy cutting and deformation of aluminum bar?

- Aluminum Alloy with the grade increased, the hardness is gradually rising, can try the next 6 series such as 6061, the machining deformation with selection of cutting fluid, because the process will produce high temperature, Aluminum Alloy heating become soft, resulting in deformation and sticking to the knife and other issues, semi synthetic cutting fluid has good cooling, lubrication and cleaning effect of processing, the most suitable Aluminum Alloy,

- Q:What does "T4" mean in the material of aluminum bar?

- 1, aluminum is mostly heat treatment, but because of the application of different occasions, so the heat treatment of the material after the state is divided into T1~T10, a total of ten levels, called the state subdivision level, for different purposes.

- Q:Formula for calculation of aluminium rods

- All by the CM countRadius * radius *3.14*, length *0.00275... Units are converted to centimeters! All that comes out is the weight;Aluminum (Al) is a kind of light metal. Its compounds are widely distributed in nature. The resources of aluminum in the crust are about 400~500 tons, second only to oxygen and silicon, and it ranks third. Among the metal varieties are the largest metals. The chemical and physical properties of special aluminum has not only light weight, firmness, texture and good ductility, electrical conductivity, thermal conductivity, heat resistance and resistance to radiation, is an important basis for national economic development of raw materials.

- Q:Where can I buy a book about aluminium bars?

- Hello, you say these are not cast out, is Aluminum Alloy stamping molding technique if casting, the cost will be very high, and the qualified rate and low rate of finished products as a professional mold, do these mold manufacturers, as long as you are drawing, they will make the corresponding mold they can also include, mold design

- Q:Now there's a company that makes aluminum alloy ingots and aluminum bars. I wonder if it's ok

- Now electrolytic aluminum project is not allowed to go up? Will productivity reductions make the market any better? Are aluminum alloy ingots and aluminium bars already saturated?Chasing the answer1, electrolytic aluminum project investment is too large, and alumina, electricity and other resources dependent2 in the existing electrolytic aluminum competition is northwest of head broken and bleeding, add 7 million tons of production capacity3, the reduction of electrolytic aluminum production capacity will not necessarily make the alloy market to do well, but also depends on their respective resource advantages and product advantages4, China's rapid economic development, aluminum consumption demand is very large, the aluminum market is still optimistic5, even if the market is saturated, as long as the raw materials, sales, market resources, as long as your product quality is absolutely good, you will always have the right to control competition. Don't look at the others in the market, to see whether they are strong enough; resources can price, technology can spell the high-end market; if the resource is no advantage, don't squeeze you.

- Q:Our company needs to make the aluminum bar 10 in diameter to be "U", which is done by hand, which is slow. Where is there such a bending device, or is it a fully automatic equipment?

- Ha ha, tell you there is a reward? 10 of the aluminum rod diameter is very small, you can consider using bending machine, or combined punching and shearing machine, punching machine or automatic equipment, how do you want to fully automatic method, to 6 meters of raw materials made directly over U segments, such a down nearly 100 thousand.

- Q:6061-T6 hardness of 6061 aluminum bar, now what price is there anyone knows?

- 6061 is a deformed aluminum alloy material grade, T6 refers to the aluminum alloy heat treatment state, T6 means that aluminum alloy by solid solution heat treatment and artificial aging, aluminum alloy T6 state hardness is the highest.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

8011 Household Aluminium Foil for Baking Cooking

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords