76% Rotary/ Shaft/ Round Kiln Alumina Calcined Bauxite Raw Material for Refractory

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

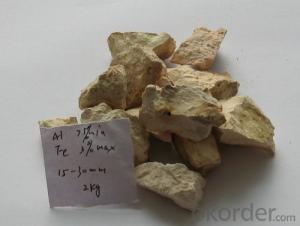

76% Rotary/ Shaft/ Round Kiln Alumina Calcined Bauxite Raw Material for Refractory

Introduction

Calcined bauxite is one of the principal ore of aluminum. Calcined bauxite contains hydrous aluminum oxides and aluminum hydroxides, formed through the laterization of aluminous rocks in tropical and subtropical areas .calcined bauxite is obtained by calcining (heating)superior grade bauxite at high temperature (from 85OC to 1600C) .this removes moisture thereby increasing the alumina content. compared to an alumina content of about 57%to 58%in raw bauxite, calcined bauxite has an alumina content of 84%to88%.the heating is carried out in rotary kilns

1.Applications

Raw bauxite is typically classified according to its intended commercial application,such as abrasive ,cement ,chemical, metallurgical, and refractory .as raw material for use in high alumina and super duty refractory bricks and shapes ,plastics ,castable refractory, motors, gun mixes, ramming mixes, abrasive grains and other products.

2.specifications

Item | Al2O3 | Fe2O3 | TiO2 | K2O+Na2O | CaO+MgO | Bulk density |

GAL65 | ≥65 | ≤2.5 | ≤4.0 | ≤0.3 | ≤0.5 | ≥2.6 |

GAL75 | ≥75 | ≤2.5 | ≤4.0 | ≤0.3 | ≤0.5 | ≥2.7 |

GAL80 | ≥80 | ≤2.5 | ≤4.0 | ≤0.3 | ≤0.5 | ≥2.8 |

GAL85 | ≥85 | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.0 |

GAL86 | ≥86 | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.1 |

GAL87 | ≥87 | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.2 |

GAL88 | ≥88 | ≤1.8 | ≤4.0 | ≤0.25 | ≤0.5 | ≥3.25 |

GAL90 | ≥90 | ≤1.8 | ≤4.0 | ≤0.25 | ≤0.5 | ≥3.25 |

Calcined Bauxite Grade:

1.Refractory Grade: |

Refractory grade bauxite has high refractoriness, good mechanical strength and moderate slag resistance. Bauxite in the refractory industry is typically used in ladle working lining, tundish furniture, delta sections, general perpose repairment, aluminium melting furnace and mineral processing.

3. Rotary calcined bauxite: |

Rotary Kiln Bauxite, as the name suggests, it is the bauxite produced by rotary kiln. there are three kinds of kilns for bauxite production mainly, rotary kiln, shaft kiln and round kiln.

4. Shaft kiln calcined bauxite: |

Shaft kiln bauxite, the bauxite calcined by shaft kiln. the raw material-bauxite ore is loaded from the top of kiln together with coal powder and combustion improver,the fire of calcination comes from kiln bottom, about 1300-1400 ℃After the complete calcination, the bauxite is carried out from the bottom.

Packaging & Delivery

Packaging Details: In bulk or in 1-1.25mr bag

Product Pictures:

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q:How long is the duration of fire resistance of hollow glass magnesium board

- Hollow glass magnesium board features fire prevention, waterproof, tasteless, non-toxic, not frozen, not rot, not crack, unchanged, non burning, high strength and light weight, convenient construction, long service life and so on, and it has more characteristics among products of the same kind nationwide. Its fire resistance limit is 0.65℃.

- Q:What problems should be paid attention to while using refractory materials under a controlled atmosphere?

- Pay attention to the performance of the materials, and the use of non oxide materials!

- Q:The primary problem, does the gas permeable brick is fired refractory bricks(refractory) ?

- Yes. After moulding by casting in the firing of 1450 ° degrees.

- Q:What are the types of steel refractory materials

- The major category is classified as permanent layer, working lining. Specific varieties: Air permeable brick (corundum). steel ladle brick (magnesia or corundum), permanent layer castable (high alumina), reinforcing material for ladle bottom, repair material for the edge of tank and so on.

- Q:What are the best refractory materials in 2,400 Celsius degree?

- You can try zircon sand which has a melting point of 2430.

- Q:What types does refractory floor include?

- The categories of refractory are: 1. the best overall performance stone flooring (waterproof, fire retardant) The full name is microcrystalline stone flooring. It is a high-performance waterproof and fire-retardant environmental wood floor synthesized with high and new technology. Its unique raw material is ground calcium carbonate micro-crystalline polymer stone with natural resin and other twenty more imported spreadings. It is formed by refining with high temperature (300 degree centigrade) and high pressure (9,000kg). It is an environmental healthing high-performance material. Its product is innocuous and unpoisonous, and won't age, deform, fade while it is fire retardant, waterproof, maintenance-free and quality, so it is an inevitable repalcement with traditional wood floor. This product has been confirmed as national key promotion program. 2. Wear-resistant composite solid wood floor It is also known as super wear-resistant multi-layer solid wood floor. First stiffening layer surface (based on inorganic materials and steel fibers for paper impregnated with thermosetting amino resin with solid wood or plywood blockboard substrate surface as a combination of facing layer), the front is wear-resistant layer, and the back is balance layer. Thtough hot pressing, it is a grooved and tongued floor, a new impregnated paper laminate floor. It also has the same wear-resistant quality as laminate floor, beauty and foot feel as solid wood floor, stable structure as solid wood composite floor, etc. 3. Waterproof plastic wood floor Plastic wood (also known as "wood plastic" or "plastic wood") composites, and the English name is WOOD-PLASTIC-COMPOSITES, WPC for short.

- Q:The effect of a high content of water in liquid resin exerted on refractory material?

- For one thing, Substandard whiteness, transportation, low quality and the storage of refractory material may account for this. For another, a high content of moisture reduced the performance of refractory material. A high content of moisture is equal to buy water with same money in terms of trade settlement. Based on this, we can’t consider the super-standard water content from a single aspect, because the water content in refractory material is definitely super-standard, and another problem is particle size. Many people hold the idea that excessive amount of water content may revive its original performance, but it tends to have influenced the quality of refractory material.

- Q:Who knows the classifications of magnesia refractory?

- They can be devided into two major categories of fettling magnesite grain and magnesite products. They can be divided into fettling magnesite grain, magnesia?brick, magnesia-silica brick, magnesia-alumina brick, magnesium-calcium brick, magnesia-carbon brick and other varieties according to the chemical compositions and purposes Its performance is greatly affected by CaO / SiO2 ratio and impurities. The load softening point and thermal shock resistance of high purity magnesia brick are much higher than those of the general magnesia bricks. It has high refractoriness and good resistance for alkaline slag and iron slag, which is an important kind of advanced refractory material. Magnesia products are mainly produced by sintering, and sintering temperature is generally between 1500 ~ 1800 ℃. Besides, chemical binder can be added to make unburned?bricks and unshaped refractories. Mainly used in open hearth furnace, electric furnace, oxidation converter, non-ferrous metal metallurgy furnace, cement kiln and calcining kiln for basic refractory.

- Q:what textures of furnace refractories are good?

- The common one uses the ordinary aluminous fireclay brick and GB / T 3994-2005 insulating fireclay brick. The ones with excellet texture are high-grade thermal insulation refractory brick and GB / T 3995-2006 high alumina insulating firebrick, whose model is A13, the texture is alumina, A13 50u, advanced heat insulating brick B5; intermediate heat insulating brick B2, and so on. Dolomite brick: The formation of coating is of good performance and corrosion resistance, but to some extent, there exsits the f-CaO in the brick, which is easy to hydrate, and hard to transport and storage, thus less using in the production. Magnesia-chrome brick: The formation of coating is good, so it is widely used for burning zone, but the disadvantage is poor thermal shock resistance, coupled with the highly toxic positive Hexavalent Cr, so the international countries that produce and use the magnesia-chrome bricks are gradually reducing. The production unit using this brick now, please find alternatives as soon as possible.

- Q:I want to know what is the slim in the refractory bricks

- Where are you from, I can introduce to you

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

76% Rotary/ Shaft/ Round Kiln Alumina Calcined Bauxite Raw Material for Refractory

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords