750 Series Adjustable Steel Frame Formwork with Special hollow steel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

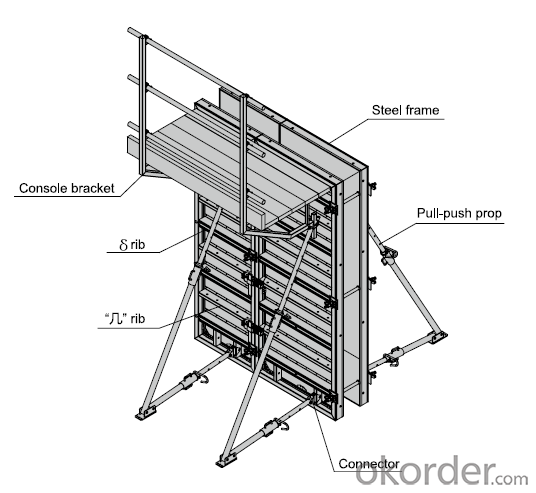

1. Structure of Steel Frame Formwork

There is a prizing part designed in the corner, which can help to position and remove formwork easily.

The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

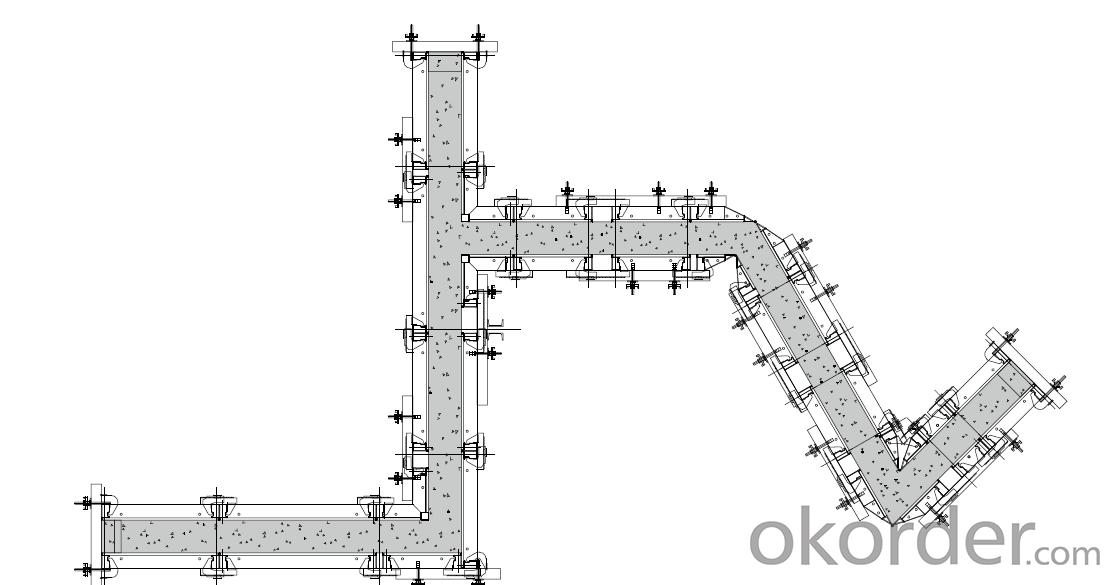

The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

2. Main Features of Steel Frame Formwork

Light weight

High strength

High standardized system

Easy connection with adjustable steel clamp

Convenient and fast corner formwork

Flexible to assemble and application

3. Steel Frame Formwork Images

4. Steel Frame Formwork Specification

-The steel frame formwork is plywood covered with hollow steel. The plywood is 18 mm thick.

-The frame is highly strengthened, and the wall formwork can bear lateral pressure 60 KN/m2 while the column formwork can bear 80 KN/m2.

-As a standardized system, it is flexible to assemble , wood batten can be filled to satisfy the need f of non-standard size.

-The adjustable steel clamp is convenient to use, and can hold tightly.

5. FAQ of Steel Frame Formwork

1) What can we do for you?

.We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Steel Frame Formwork , please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Steel Frame Formwork GK120 cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Steel Frame Formwork , we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q:What are the different types of formwork hinges used with steel frame formwork systems?

- Steel frame formwork systems commonly use various types of formwork hinges to provide flexibility and ease of use during the construction of concrete structures. Here are the different types of formwork hinges used with steel frame formwork systems: 1. Fixed Hinges: The most basic formwork hinge in steel frame systems, fixed hinges are installed at a specific angle and cannot be adjusted afterward. They are suitable for straight walls or columns without the need for angular adjustments. 2. Adjustable Hinges: Offering flexibility, adjustable hinges allow users to change the formwork angle. Equipped with a locking mechanism, these hinges let users set and secure the desired angle. They are often utilized for walls or columns requiring angular adjustments. 3. Sliding Hinges: Sliding hinges are ideal when horizontal or vertical movement of the formwork is necessary. These hinges have a sliding mechanism that enables adjustments to the desired position. They prove especially valuable during the construction of complex structures or when modifications are needed. 4. Swivel Hinges: For rotating the formwork, swivel hinges are employed. These hinges have a swiveling mechanism that allows the formwork to be rotated as required. They are commonly used in the construction of curved walls or structures demanding specific curvatures. 5. Combination Hinges: Combination hinges merge the functionalities of adjustable, sliding, and swivel hinges. With these hinges, users have maximum flexibility to set the formwork at any desired angle, position, or rotation. They are extensively used in complex structures where multiple adjustments may be necessary. In conclusion, the variety of formwork hinges available for steel frame formwork systems ensures the necessary adaptability and flexibility required to meet different construction needs. By utilizing these hinges, construction professionals can accurately and efficiently build concrete structures while upholding high standards of quality and safety.

- Q:Can steel frame formwork be used for both large and small-scale construction projects?

- Steel frame formwork is applicable to construction projects of both large and small scales. It is renowned for its durability and strength, which renders it suitable for various construction projects, irrespective of their size. Stability and support are guaranteed by the steel frame, ensuring that the formwork can endure the pressure and load of the concrete during the casting process. Moreover, the design of steel frame formwork allows for flexibility and easy assembly and disassembly, enabling efficient utilization in projects of different sizes. Its reusability makes it a cost-effective solution for both large and small-scale projects since it can be used multiple times. In conclusion, steel frame formwork is a versatile and dependable option for construction projects of any magnitude.

- Q:How does steel frame formwork contribute to the overall speed of construction?

- The overall speed of construction is enhanced by steel frame formwork in several ways. To begin with, this type of formwork is designed to be reusable, allowing it to be used for numerous construction projects. This not only saves time but also reduces the cost of procuring formwork. As a result, there is no longer a need for traditional timber formwork, which typically requires construction and dismantling for each project. Moreover, steel frame formwork is easy to handle and lightweight, enabling quick and efficient installation. As a result, workers can easily move and position the formwork panels without the use of heavy machinery or excessive manpower. This expedites the construction process significantly. In addition, steel frame formwork is extremely versatile and can be adjusted to fit various shapes and sizes. This adaptability allows for different architectural designs to be accommodated, thereby streamlining the construction process. By using the same formwork system for different parts of the project, there is no longer a need for custom-made formwork for each specific component. Furthermore, steel frame formwork offers exceptional stability and strength, guaranteeing the accuracy and quality of the concrete structures. Consequently, there is no longer a need for excessive remedial work or repairs, saving time and resources that would otherwise be spent on rectifying errors. In conclusion, steel frame formwork contributes to the overall speed of construction through its reusability, lightweight nature, versatility, and provision of stability. These factors enable faster and more efficient construction, resulting in reduced project timelines and enhanced productivity.

- Q:What types of projects are steel frame formwork suitable for?

- Steel frame formwork proves to be a suitable option for a wide range of construction projects, specifically those necessitating a robust and long-lasting formwork system. Commonly, steel frame formwork is employed in projects like high-rise buildings, bridges, tunnels, dams, and large-scale infrastructure projects. The resilience and capacity to endure substantial loads make steel frame formwork the ideal selection for projects involving extensive concrete pouring or those requiring a high degree of structural integrity. The steel frame furnishes exceptional support and stability, guaranteeing that the formwork system can withstand the pressure exerted by the wet concrete. Moreover, steel frame formwork exhibits high adaptability, allowing for easy customization to meet diverse project requirements. It can be adjusted to accommodate various shapes, sizes, and dimensions, rendering it suitable for projects involving intricate architectural designs or unique structural elements. Additionally, steel frame formwork is reusable, presenting a cost-effective solution for projects necessitating repetitive casting of concrete elements. In conclusion, steel frame formwork is a well-suited choice for projects demanding strength, durability, and versatility. Its ability to handle heavy loads, adapt to various shapes, and be reused makes it an excellent option for high-rise buildings, bridges, tunnels, dams, and large-scale infrastructure projects.

- Q:Can steel frame formwork be used for both temporary and permanent concrete structures?

- Yes, steel frame formwork can be used for both temporary and permanent concrete structures. Steel frame formwork is a versatile and durable system that is capable of withstanding the pressures and forces exerted during the concrete pouring process. It provides a stable and secure framework for pouring and shaping the concrete, ensuring accurate dimensions and a high-quality finish. For temporary structures, steel frame formwork can be easily assembled and disassembled, allowing for quick and efficient construction. It is commonly used for projects such as bridges, tunnels, and temporary structures like staging platforms. Once the concrete has cured, the formwork can be dismantled and reused for other projects. For permanent structures, steel frame formwork can also be utilized. Its strength and durability make it suitable for long-term use, especially in projects where the formwork needs to remain in place to support the structure. Steel formwork can withstand the weight and pressure of the concrete, providing the necessary support until the structure reaches its full strength. However, it is important to note that steel frame formwork may require additional protection or surface treatment for permanent structures to prevent corrosion and ensure long-term durability. This can be achieved through various methods such as applying protective coatings or using corrosion-resistant materials. In conclusion, steel frame formwork is a versatile solution that can be used for both temporary and permanent concrete structures. Its strength, durability, and ease of use make it a popular choice for construction projects of all scales.

- Q:How does steel frame formwork prevent the formation of concrete cracking during curing?

- Steel frame formwork prevents the formation of concrete cracking during curing by providing a strong and rigid support structure that holds the concrete in place and prevents it from shifting or settling. This ensures that the concrete maintains its intended shape and structural integrity throughout the curing process, minimizing the risk of cracks forming due to uneven curing or excessive stress.

- Q:How does steel frame formwork contribute to better dimensional accuracy in precast elements?

- Steel frame formwork contributes to better dimensional accuracy in precast elements by providing a rigid and stable structure that ensures precise alignment and positioning of the concrete during the casting process. The steel frame acts as a strong support system, preventing any deformation or movement that could result in inaccuracies or variations in the final dimensions of the precast elements. Additionally, the steel formwork allows for easy adjustments and fine-tuning, enabling precise control over the shape, size, and overall dimensional accuracy of the precast elements.

- Q:How does steel frame formwork contribute to the overall strength and stability of a structure?

- Steel frame formwork is a crucial component in the construction industry that significantly contributes to the overall strength and stability of a structure. Firstly, steel frame formwork provides a robust and durable framework to support the concrete during the pouring and curing process. It acts as a temporary mold, ensuring that the concrete is poured in the desired shape and form. The steel frame formwork is designed to withstand the pressure and weight of the wet concrete, preventing any deformation or collapse during the construction phase. Furthermore, steel frame formwork allows for precise and accurate construction. The rigid and stable nature of steel ensures that the formwork maintains its shape and alignment, resulting in a consistent and uniform structure. This is particularly important when constructing large-scale projects or structures with complex designs, as any deviation or inconsistency in the formwork could compromise the overall strength and stability of the structure. Moreover, steel frame formwork enhances the structural integrity of the building. The steel framework provides additional reinforcement to the concrete, making the structure more resistant to external forces such as wind, earthquakes, and heavy loads. By distributing the load evenly across the structure, steel frame formwork minimizes the risk of structural failure and increases the overall stability of the building. Additionally, steel frame formwork offers versatility and adaptability. It can be easily adjusted and modified to accommodate changes in design or construction requirements. This flexibility allows for efficient construction processes and reduces the need for additional materials and resources. Overall, steel frame formwork plays a vital role in ensuring the strength and stability of a structure. Its robustness, precision, reinforcement capabilities, and adaptability contribute to the overall integrity and durability of the building, making it a crucial component in the construction industry.

- Q:Can steel frame formwork be used for healthcare and medical facilities construction?

- Healthcare and medical facilities construction can indeed utilize steel frame formwork. The strength, durability, and versatility of steel frame formwork make it suitable for a range of construction projects, including healthcare and medical facilities. It offers a stable and secure framework capable of supporting heavy concrete structures, ensuring the safety and stability of the building. Furthermore, steel frame formwork can be easily assembled, disassembled, and adjusted, allowing for flexible design and efficient construction processes. In addition, steel is a non-combustible material, which is crucial for healthcare and medical facilities that must adhere to strict fire safety standards. In summary, steel frame formwork is a dependable and efficient option for the construction of healthcare and medical facilities.

- Q:How does steel frame formwork ensure proper alignment of columns and beams?

- Steel frame formwork ensures proper alignment of columns and beams by providing a rigid and stable structure that holds the concrete in place during the pouring and curing process. The steel frame formwork system is designed to be adjustable and customizable, allowing for precise positioning of the columns and beams. This ensures that they are aligned correctly and in the desired location, resulting in a structurally sound and visually appealing finished product.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

750 Series Adjustable Steel Frame Formwork with Special hollow steel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products