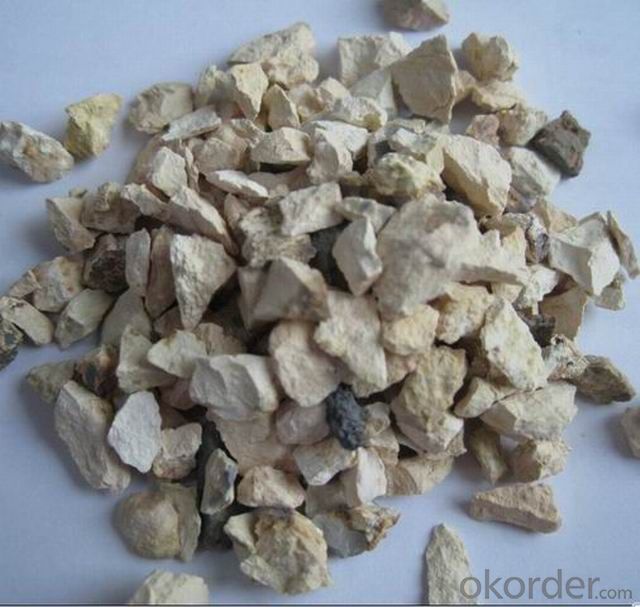

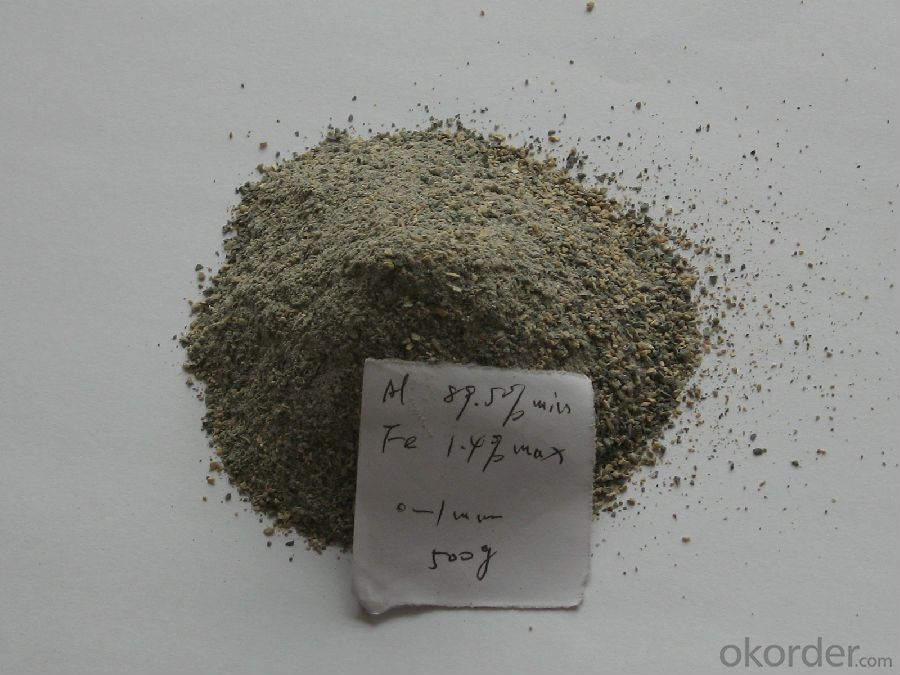

75% alumina 1-3mm calcined bauxite with low price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

75% alumina 1-3mm calcined bauxite with low price

Specifications

1,Manufacturer-Direct sale

2,Good fireproof insulation

3,High bulk density

Our Advantages;

1. We have substantial experience for material manufacture and export.

2. We establish a long-term relation of cooperation with raw material supplier, so we can offer you the best quality and price.

3. We have equipped 8 production lines and skilled workers to make the quality best.

4. We can control strictly quality at factory and third party testing institutions quality inspection.

5. We can also offer you the related test report, both at factory and the third party testing institutions.

6. We have sufficient manufacturing capability to deliver the goods safely and timely.

7. We can pack in 25kg bags, 1mt big bags, 1.25mt big bags or as your request. We can also pack with pallet.

8. We have professional service team keep customers informed from delivery to discharge.

Product Description:

Bauxite, alumina or bauxite miner , main ingredients are aluminum oxide, hydrate alumina containing impurities,

is an earthy mineral.White or grey, brown yellow or light red by iron.From 4 to 3.9 g/cm3 density, hardness, 1 ~ 3, opaque, very brittle.

Very difficult to melt.Insoluble in water, soluble in sulfuric acid, sodium hydroxide solution.Mainly used for aluminium, refractory material.

Packaging & Delivery

Packaging Details: In bulk or in 1-1.25mr bag

Product Pictures:

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q:What crusher is used for raw material of broken refractory material? What is the rough crushing process? What are the materials? Thank you!

- What is said above ia wrong. Crusher choosed by general refractory material factory is roller type, for example: Roll crusher,teeth-roller?cracker. Choose different crushing equipment according to your requirements. You can go "Zhengzhou Keda Machinery Co., Ltd." to inspect! ! ---Hope it is helpful to you!

- Q:What are fire?ratings of wall thermal insulation material?

- Grade A material has no ignition and is material with thermal insulation effect, anti-combustion material. Currently it mainly refers to inorganic thermal insulation mortars of vitrified micro bead, hole-closed?expanded perlite, rock wool,mineral wool,glass wool,cement base or gypsum base, inorganic thermal insulation mortars and self thermal insulation system of lightweight block. Grade B1 is nonflammable thermal insulation material, which is determined by fire endurance of this material. In addition, the division of the material of different parts is different! What is commonly seen, such as EPS / XPS insulation boards adding flame retardant through special treatment. Grade B2 is combustible thermal insulation materials, and what is commonly seen is EPS expanding polystyrene board and XPS extruded polystyrene board, that is, the general board. This material has low ignition point, and releases large amounts of harmful gases in the combustion process . Grade B3 is flammable insulation material. Thermal insulation material with polyphenyl foam as main material is commonly seen. Since this material is highly flammable, it has been eliminated external wall thermal insulation materials.

- Q:Would you like to know if there are any enterprises in Mianyang that need fire-resistant materials?

- Big business needs to be usedIntroduce several big: Jiuzhou 208827 and Changhong

- Q:What are grade classifications of the external walls fireproofing material?

- 1. The thermal insulation material of level A combustion performance: Rock wool, glass wool, foam glass, foamed ceramics, foam cement, hole-closed perlite, etc. 2. combustion performance is level B1 insulation materials: Extruded polystyrene board (XPS) after special treatment / Special treatment of polyurethane (PU), phenolic aldehyde and gelatine powder polyphenyl granule 3, combustion performance is level B2 insulation material: Molding polystyrene board (EPS), extruded polystyrene board (XPS), polyurethane (PU), polyethylene (PE), etc. See the 2009 edition construction technical measures 4.3.6 Level A insulation material is only for fireproofing, but its thermal insulation performance is not better than organic XPS \\ EPS and other materials.

- Q:Refractory inquiries

- Special refractories are new inorganic non-metallic materials developed on the basis of traditional ceramics and refractory materials.

- Q:How should refractory cement be used?

- Refractory cement is very easy to use. Add some water and mix, and it will harden. Generally there is no need to add other binding agents, but you can add some refractory aggregate and powder. If you use only refractory cement, it will generate a lot of cracks after high temperature. Generally refractory cement can withstand temperature of about 1300 degrees.

- Q:What is the acceptance standard of refractory?

- Feeler gauge is used to check the thickness of the refractory brickwork joint. The top of the gauge can not be sharpened. Feeler gauge is of the width of 15mm, length of 100mm and thickness of 1, 1.5, 2 or 3mm. The thickness is eligible when the depth which the feeler gauge is inserted in is less than or equal to 20mm. Ten places should be inspected per 5m2 of masonry surfaces. It is qualified when the condition in which thickness of the brickwork joint is 50% larger than a predetermined depth is not less than five times and it is excellent when the condition is no more than two times.

- Q:Who knows which chrome refractories produced by the Henan refractory plant can be used for continuous casting?

- Field casting experiments are needed to verify,

- Q:What do RH and DH stand for in refractories?

- DH :An agreement that allows strangers to build shared keys, originally invented by Diffie and Hellman.

- Q:What is glass furnace used high-grade refractory materials?

- It is said that building a furnace need 30 million? After the ignition, it can't be gone out. Only at the waste to maintenance?

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

75% alumina 1-3mm calcined bauxite with low price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords