7.5kw 380v 3 phase variable frequency drive ac motor controller

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 300 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Brand:CHINSC

2.37kw variable frequency drive

3.MOQ:1 set

4.Best price and quality

5.Quick delivery time

Technical Specification

Item | Specification | |

Input | Rated voltage | T4 series: Three phase 380v, ±15% |

Frequency | 50/60Hz ±5% | |

Output | Voltage | Three phase 0-380V |

Frequency | 0-600Hz | |

Overload ability | Type G: 150% rated current for 1 minute, 180% rated current for 2 second; Type P: 120% rated current for 1 minute, 150% rated current for 2 second. | |

Heat Dissipation | Cooling type | Forced Cooling |

Temperature protection | Heatsink temperature >85degree trip protection against overheat | |

Fan control | Heatsink temperature> 50degree, fan forced operation, frequency inverter continue work | |

Control Performance | Control mode | Open-loop vector control, V/F control, Torque Control |

Start torque | Open-loop vector control: 0.5Hz 180%; VF control:0.5Hz 150% | |

Speed range | Open-loop vector control: 1:200; VF control:1:100 | |

Speed control precision | Open-loop vector control: ±0.2%; VF control:±0.5% | |

Torque control precision | Open-loop vector control: ±5% | |

Torque response time | Open-loop vector control: <20ms< span=""> | |

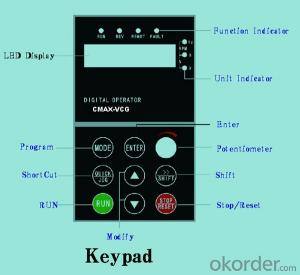

Function | Channel of operation command | Keyboard control,terminal control,communication control |

Start mode | Direct start, DC injection braking before start, speed tracking before start | |

DC injection braking | Start DC injection braking, stop DC injection braking | |

Dynamic braking | Built-in braking unit < = 11kw, get external braking unit>15kw | |

Frequency source choice | Keyboard digital frequency setting, analog V1 setting, analog V2 setting, Keyboard potentiometers setting, Multiple speed operation setting, PID control setting, telecommunications setting, PLC program operation setting, HDI High Speed Pulse setting | |

Main and auxiliary frequency combination set | Just main frequency setting, just auxiliary frequency setting, QUICK/JOG or terminal switching selection, main frequency + auxiliary frequency, main frequency - auxiliary frequency, maximum, minimum, could realize Frequency overlay and fine adjustment function | |

Frequency resolution | Keypad setting:0.01Hz; Analog setting: 0.1% | |

Carrier frequency | 0.5Khz~15.0Khz, both PWM mode could be chosen | |

Acc/Dec time | 0.1~3600.0s | |

Multiple VF curve | Linear V/F curve, 2.0 times power drop torque V/F curve, custom V/F percentage (can realize manual energy saving control), multipoint VF curve. | |

Built-in PID | Built-in PID controller, apply to process control occasion such as water or gas supply. Meanwhile the sleep wake up function could save energy to the great extent possible. | |

Simple PLC operation | 16 segment goal setting, frequency or mode of percentage setting could be chosen, each segment of operation time and direction could be set separately, and realize timing stop function. | |

Common function | Speed tracking, Cut-off restart, fault recovery, Automatic torque promotion, the motor’s parameters auto-learning, Pendulum frequency operation, hopping frequency, UP/DOWN control, AVR, Over-voltage stalling protection, rapid current-limiting, Instant power down and drop frequency operation | |

Input Output Signal | Analog input | V1:0~10V V2:4~20mA or 0~10V, Select through JP2 jumper Keyboard potentiometer input: 0~5V |

Analog output | FM1:0~10V or 0~20mA, Select through JP9 jumper FM2:0~10V or 0~20mA, Select through JP10 jumper. Need the support of SC-EXT1-IO expansion cards | |

Digital input | Standard configuration S1~S6, can expand S7~S10 through SC-EXT3-S expansion cards. A total of 30 kinds of function could be selected. | |

Digital output | Standard configuration 2 channel including SP1, SP2 electrode output; 1 channel relay output T1; Expanding 4 channel relay output T2~T5 through SC-EXT2-R expansion cards. | |

High-speed pulse input | HDI: 0~50.0Khz, support by expansion cards SC-EXT1-IO | |

High-speed pulse output | HDO: 0~50.0Khz, support by expansion cards SC-EXT1-IO | |

Communication Port | Communication protocol | Based on RS485 hardware, support standard MODBUS protocol, should match expansion cards SC-EXT1-IO |

Expansion Cards | 3 type expansion cards | Standard expansion cards SC-EXT1-IO, Relay expansion cards SC-EXT2-R (can realize one drives 2 function), Multifunctional input expansion card SC-EXT3-S, refer to the explanation in Appendix. |

Display Functions | Five digital tube display | Can monitor the operation state of frequency inverter flexibly and conveniently; can set normal monitoring parameters separately when operation and stop. |

Protection Function | 25 kinds of protection functions | Including over-voltage, over-current, overheat, overload, under-voltage, short circuit, ground fault, input and output default phase, protect the frequency inverter running reliably all-round. |

Installation Environment Requirement | Ambient temperature | -10degree~+40degree(ambient temperature is within 40degree~50degree, derating use is required), not allow to contact direct sunlight. |

Humidity | Less than 90%RH, without condensation | |

Application environment | Non-corrosive, flammable, explosive, dust absorbent material, all kinds of lint does not accumulate. | |

Vibration | Less than0.6G | |

Elevation | 0~1000m, reduce the rated specification 10% when lift 1000m for each. | |

Storage temperature | -20~60degree | |

Factory Overview

Application

Textiles, Plastics, Ceramics, Electronics, Numerical Controls, Foods Processing, Light Industry, And Pharmaceuticals. Oil, mining and other fields.

Certification

Welcome your inquiry!

Looking forward to cooperating with you!

- Q:How to choose a Siemens inverter for a 5.5KW three-phase motor (2 pole)?

- Beijing easy to create a website with Siemens inverter selection manual! You can log on online! Or contact them directly, they will give you professional answers!

- Q:How is the notebook with a power adapter?

- Clear use: Home use and office with the laptop power adapter to buy a home (AC), the car with the laptop power adapter, to buy a car, you want to use the aircraft on the basis of the car with a The aircraft head on it. Home, car, plane, want to take into account, to buy a two-in-one, or three in one. But if you do not want a few bags of computer weight, you can put a home, put a car, the office put a, so you can not bring to bring, plug to plug, more convenient, you can also give people around

- Q:If it is 8-pole variable frequency motor, enter the motor nameplate parameters in the inverter input for the 4 pole can?

- If the control accuracy is not high, then you can use the ordinary control. Since the choice of the inverter, it is best based on the motor nameplate to set parameters to ensure the stability of the motor running

- Q:Laptop adapter heat

- In fact, as long as the power adapter temperature is within the design range, that is, the temperature in the normal range, the general is not dangerous! So why is the power supply hot? What kind of temperature range is the normal range? Switching power supply conversion efficiency can only reach 75% -85% or so. The answer is here. Switching power supply conversion efficiency is high enough, it is still difficult to find a better way to convert. Switching power supply in the voltage conversion, a part of the energy loss, in addition to a small part of the loss in the form of waves, the majority of the way out of the heat. Switching power supply power is missing, the loss of energy is also missing, the power of the heat is also large. This is why the desktop power supply to add a fan for cooling reasons. We may wish to count, a 100W switching power supply, in the use of how much energy loss in the above!

- Q:ASUS notebook power adapter can be universal? is it?

- Under normal circumstances, as long as other ASUS notebook power adapter voltage, current and interface with your notebook the same, you can use. Not ASUS adapter even if the voltage, the interface is the same is best not to use, easy to cause damage to the computer. I suggest you can call the ASUS national service hotline to see, consult the current market can support your laptop adapter model, and then to the computer store or online purchase. If you feel that my answer is satisfied, please adopt Wo take

- Q:Inverter signal line analog 4-20mA connection positive and negative can be reversed?

- Theoretically reverse seems to be possible, but the operation will be normal, you can do experiments to try what is the result. Various manufacturers of the inverter may be the treatment of this problem will be different.

- Q:What is the laptop power adapter? Is it the battery?

- so that the book can be normal operation, or else you think the notebook is 220V Is the voltage at work?

- Q:What is the meaning of the bipolar polarity in the inverter ah There is a +10V signal input is a -10V What is the meaning of ah?

- That is to say that the potentiometer at both ends of the line between + 10v and -10v, tap can be given with a potentiometer to control the positive and negative!

- Q:What is the base blockade in the drive?

- Normal work, the bridge between the upper and lower pipes can not be turned on at the same time, while conduction will occur short-circuit accident. It is necessary to open a tube at the same time block the same bridge of the other pipe base can be safe to work.

- Q:How do I select a drive? Which brand is better

- ???4, when the inverter is used to control several motors in parallel, be sure to consider the inverter to the motor cable length of the sum of the inverter in the allowable range. If you exceed the specified value, to enlarge one or two steps to select the inverter. In addition, in this case, the inverter control mode can only be V / F control mode, and the inverter can not protect the motor over-current, overload protection, this time in each motor on the fuse to achieve protection. ????5, for some special applications, such as high ambient temperature, high switching frequency, high altitude, etc., this time will cause the inverter derating, the inverter need to enlarge a file selection. ????6, the use of inverter control high-speed motor, due to high-speed motor reactance small, high harmonics also increase the output current value. Therefore, when selecting a frequency converter for a high-speed motor, it should be slightly larger than the inverter of an ordinary motor. ????7, the inverter for the variable pole motor, should pay full attention to select the inverter capacity, so that the maximum rated current in the inverter rated output current below. In addition, in the operation of the number of pole conversion, you should first stop the motor work, otherwise it will cause the motor idling, bad will cause damage to the inverter.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

7.5kw 380v 3 phase variable frequency drive ac motor controller

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 300 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products