6 inch Welded Stainless Steel Pipe 316l handrails

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description

C | Si | Mn | P | S | Ni | Cr | |

| SS304 | 0.046 | 0.316 | 1.481 | 0.0424 | 0.0028 | 8.001 | 18.019 |

| SS201 | 0.111 | 0.31 | 9.45 | 0.029 | 0.006 | 0.871 | 14.110 |

| SS316 | ≤0.08 | ≤1 | ≤2 | 0.035 | 0.03 | 1.0~14.0 | 16.0~18.5 |

Shape | Round / Square Etc. |

Brand | PEMCO/OEM/ODM |

Material | SS Stainless Steel 201, 304 , 316 |

Quality | First Grade |

Finish | Satin/Mirror |

Technology | Casting |

Certificate | ISO 9001-2000 |

Application | *Construction And Stair , Handrail , Railing Use |

*Shopping Mall,House,Outdoor | |

Feature | Beautiful Outlook, Easy To Clean, Low Maintenance Cost |

Usage | Widely Used On Stainless Steel Balustrade & Handrails, Indoor Or Outdoor Decorations,Etc. |

MOQ | 10 Pieces |

Delivery Time | 15-20 Days |

Colors for you to choose:

hot sale

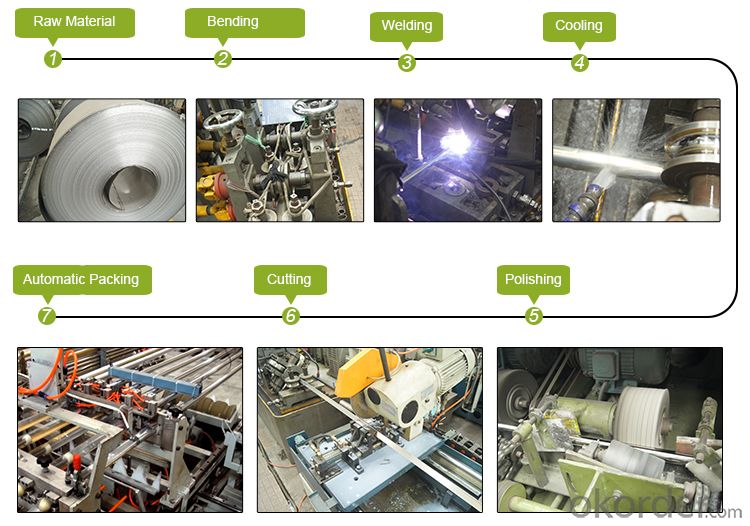

Production Process

Our Services

Pre-sale service:

1. Quotation: stainless steel pipe handrails price will be quoted according to material grade, size, thickness, length of each piece, finish and your quantity you want.

2. Sample: free samples can be sent for your reference.

3. OEM/ ODM Service: Your 2D/3D drawings or samples are welcome.

4. Other reasonable requests: factory photos, test reports, certifications, etc. to show.

Sale service:

1. Payment Method:

For samples, freight can be paid via Paypal, Westernunion or to our bank account.

Deposit and the balance can be paid via bank account or Alibaba Onetouch.

2. Business Term: EXW, FOB, CIF, etc.

3. Delivery: To door service - Internationl Express (DHL, FedEx, TNT, etc.)

Airport or shipping transportation

4. Payment and Shipping Terms:

Alibaba Onetouch Paypal Western Union Bank Transfer

- Q:Are stainless steel pipes resistant to chemicals?

- Yes, stainless steel pipes are generally resistant to chemicals. Stainless steel is known for its corrosion resistance properties, which makes it an ideal material for various applications, including pipes that are exposed to different chemicals. The high levels of chromium in stainless steel create a protective layer on the surface of the material, preventing it from reacting with most chemicals and corrosive substances. However, it is important to note that the resistance of stainless steel pipes to chemicals can vary depending on the specific type and grade of stainless steel used. In some cases, certain aggressive chemicals or extreme conditions may still cause corrosion or damage to stainless steel pipes, so it is always advisable to consult with experts or refer to specific chemical resistance charts for accurate information on the compatibility of stainless steel pipes with different chemicals.

- Q:What brand of stainless steel pipe cutting machine is good?

- Cut stainless steel tube, choose what brand is good, not the most important, first of all depends on what method to cut the best, the current cutting methods are saw blade, saw blade, laser, plasma, turning tools and so on.

- Q:How do you prevent backflow in stainless steel pipes?

- There are several essential measures that can be taken to prevent backflow in stainless steel pipes. Firstly, the installation of a backflow preventer is crucial. This mechanical device ensures that water flows in only one direction, effectively preventing any backflow. Various types of backflow preventers, such as check valves, double check valves, and reduced pressure zone devices, are available. The selection of the appropriate one depends on the specific system requirements and local codes and regulations. Regular maintenance and inspection of the backflow preventer are also important. It is necessary to ensure that the device is functioning properly and promptly address any signs of wear or damage. Regular maintenance may involve cleaning and replacing worn-out parts to maintain optimal performance. Maintaining proper pressure in the stainless steel pipes is another preventive measure. High pressure can lead to water flowing in the opposite direction, causing backflow. By installing pressure regulators or pressure-reducing valves, the water pressure can be controlled and kept within the recommended range. Incorporating air gaps into the system provides an additional layer of protection against backflow. Air gaps create a physical separation between the water source and the point of use, eliminating any direct connection that could allow backflow to occur. Proper system design is also crucial in preventing backflow. This includes ensuring correct sizing of the stainless steel pipes, appropriate slope, and proper connections. Additionally, locating the backflow preventer in an easily accessible area facilitates regular maintenance and inspection. By implementing these preventive measures, the risk of backflow in stainless steel pipes can be significantly reduced. This promotes the safe and efficient flow of water in the system.

- Q:Why can't stainless steel tubes be cut with acetylene?

- That is because the iron element in the high temperature, if the above 99,6% will occur on the oxygen oxidation phenomenon is very strong, because of the heat transfer cycle, in order to make the cutting to continue uninterrupted, continuous heating it when cutting calories.

- Q:Can stainless steel pipes be used in power plants?

- Indeed, power plants can utilize stainless steel pipes. Thanks to its remarkable resistance to corrosion, stainless steel proves to be an ideal material for a wide range of power plant applications, especially when dealing with high temperatures, pressures, and corrosive surroundings. In power plants, stainless steel pipes serve the purpose of fluid transportation, including water, steam, and chemicals. Additionally, they find their place in several components like heat exchangers, boilers, condensers, and turbines. The dependability, robustness, and corrosion resistance of stainless steel make it an undeniable and trustworthy option for power plant endeavors.

- Q:What are the different types of stainless steel pipe bends?

- In the market, one can find various stainless steel pipe bends with different characteristics. Some commonly used types include: 1. Long radius bends: These bends have a larger radius compared to other types, resulting in a smoother flow of fluid or gas through the pipe. They are suitable for applications where a consistent flow speed is required or when there are concerns about pressure drop. 2. Short radius bends: These bends have a tighter curvature due to their smaller radius. They are typically used in limited space applications, such as tight corners or compact piping systems. 3. U-bends: U-bends form a U-shape with a 180-degree curve. They are commonly used in heat exchanger systems to efficiently transfer heat between fluids. 4. 3D bends: With a radius three times the diameter of the pipe, 3D bends offer a gradual change in direction, resulting in a smoother flow compared to sharper bends. 5. 5D bends: 5D bends have a radius five times the diameter of the pipe. They are used when strict requirements for fluid or gas flow are necessary, minimizing pressure drop and turbulence. 6. Mandrel bends: These bends are created using a solid rod called a mandrel inserted into the pipe during the bending process. This helps maintain the shape and integrity of the pipe, resulting in a smooth and uniform bend. Mandrel bends are ideal for applications where roundness and smoothness are crucial. It is crucial to select the appropriate stainless steel pipe bend based on specific application requirements, such as the transported fluid or gas, pressure and temperature conditions, and any spatial limitations. Seeking advice from professionals or suppliers can ensure the correct selection of pipe bends for a particular application.

- Q:Can stainless steel pipes be used for chemical reactors?

- Yes, stainless steel pipes can be used for chemical reactors. Stainless steel is known for its excellent corrosion resistance and durability, making it suitable for handling various chemicals and maintaining the integrity of the reactor system.

- Q:Can stainless steel pipes be chrome plated?

- Yes, stainless steel pipes can be chrome plated.

- Q:What are the different end connections available for stainless steel pipes?

- There are several different end connections available for stainless steel pipes, depending on the specific application and requirements. Some of the commonly used end connections include: 1. Threaded Ends: Stainless steel pipes can have threaded ends, which allow them to be easily connected to fittings or other pipes using threaded connections. This type of end connection is commonly used in plumbing and industrial applications. 2. Socket Weld Ends: Socket weld ends are another type of end connection for stainless steel pipes. They involve inserting the pipe into a socket in a fitting and welding it in place. This type of connection provides a strong and leak-proof joint, making it suitable for high-pressure and high-temperature applications. 3. Butt Weld Ends: Butt weld ends involve welding the ends of two stainless steel pipes together. This type of connection is typically used for larger diameter pipes and provides a strong and durable joint. Butt weld ends are commonly used in industries such as oil and gas, chemical processing, and power generation. 4. Flanged Ends: Flanged ends are used when the stainless steel pipe needs to be connected to equipment or components using flanges. Flanges are flat, circular discs with raised edges that allow the pipe to be bolted to the flange. This type of connection is commonly used in industries such as petrochemical, water treatment, and HVAC. 5. Grooved Ends: Grooved ends involve cutting grooves into the ends of stainless steel pipes and using grooved couplings to connect the pipes together. This type of connection is quick and easy to install, making it popular in applications such as fire protection systems and plumbing. It's important to note that the choice of end connection depends on factors such as the pipe size, pressure rating, temperature requirements, and the specific application. Consulting with a professional or referring to industry standards and guidelines can help determine the most suitable end connection for a particular stainless steel pipe.

- Q:Are stainless steel pipes suitable for brewing systems?

- Yes, stainless steel pipes are highly suitable for brewing systems. Stainless steel is the preferred material for brewing equipment due to its excellent corrosion resistance, hygienic properties, and durability. Stainless steel pipes do not react with the acidic components present in brewing, ensuring that there are no unwanted flavors or contaminants introduced into the beer. Additionally, stainless steel pipes are easy to clean and maintain, making them ideal for the brewing process. Overall, stainless steel pipes provide a reliable and long-lasting solution for brewing systems, ensuring the production of high-quality and uncontaminated beer.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

6 inch Welded Stainless Steel Pipe 316l handrails

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords