5W CNBM Monocrystalline Silicon Panel for Home Using

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 watt

- Supply Capability:

- 1000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

5W CNBM Monocrystalline Silicon Panel for Home Using

Production description

Solar energy is radiant light and heat from the Sun harnessed using a range of ever-evolving technologies such assolar heating, photovoltaics, solar thermal energy, solar architecture and artificial photosynthesis.

It is an important source of renewable energy and its technologies are broadly characterized as either passive solar oractive solar depending on the way they capture and distribute solar energy or convert it into solar power. Active solar techniques include the use of photovoltaic systems,

Feature

1.High conversion efficiencies resulting in superior power output performance.

2.Outstanding power output even in low light or high temperature conditions

3.Optimized design for ease of soldering and lamination

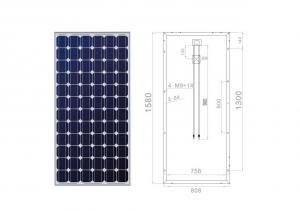

Physical characteristic

1. Rigorous quality control meets the highest international standards.

2. High-transmissivity low-iron tempered glass, strong aluminium frame.

packaging

26pcs in one carton 6pallets in 20foot container 14pallets in 40 foot container.

- Q:Do solar panels require a battery backup system?

- No, solar panels do not require a battery backup system, but it can be beneficial to have one for storing excess energy for use during cloudy days or at night.

- Q:Can solar panels be used to power a hotel?

- Yes, solar panels can be used to power a hotel. By installing a sufficient number of solar panels, a hotel can generate a significant amount of electricity to meet its power needs. This not only helps to reduce energy costs but also promotes sustainability and environmental responsibility.

- Q:If you were to shine, for example, heat lamps onto the solar panel along with the sun, will the solar panel eventually not work? Or will they produce more light as long as more light is directed onto them.

- Solar panels have a upper temperature limit, and it's only a bit more than it would reach in a very bright sunny day near the equator. Start shining heat lamps on it and you will raise it past it's max temperature, and it will die. .

- Q:Can solar panels be installed in a shaded area?

- Solar panels can still be installed in a shaded area, but their efficiency will be significantly reduced as they rely on direct sunlight to generate electricity.

- Q:Please tell me what they are made of and how the materials help the solar cell produce electricity. Im doing a science projects so i need help on knowing all this info. Its a debate, so i need correct information please.I will please need more information about the bad things about solar energy and solar panels. Please say what solar panels do to create pollution or do anything that is not friendly to the environment. If you want just give me a website. Thank you

- Solar cells are mainly made of a semiconductor called silicon,when sunshine on it,solar energy is converted into electrical energy by photovoltaic.The energy knocks electrons loose, allowing them to flow freely.This flow of electrons is a current, this current, together with the cell's voltage (which is a result of its built-in electric field or fields), defines the power (or wattage) that the solar cell can produce.

- Q:I paid for an appraisal and the home was valued at $25,000. The problem I have with this is my house is equipped with solar panels. I paid about $25000 for them. A comparable house sold for $225,000 4 months ago. Same amount of rooms, bathrooms, square feet, lot size and curb appeal (landscaping). But no solar panels. Home prices in my neighborhood have also gone up. I would like to know if there is any way I can dispute this as I feel I just wasted a lot of money on a incorrect appraisal.

- Zillow ? Great at guessing value. Start with ur property tax agencies valuation. Solar panels seldom GET any return on costs. Often creating negative value. Contact actual Realtors for neighborhoods Comparison of ur house NOT appraisal. Two different animals

- Q:What happens to solar panels during a power outage?

- During a power outage, solar panels do not generate electricity as they rely on the grid for their functioning. This is because most solar panel systems are grid-tied, meaning they are designed to feed excess power back into the grid and draw power from the grid when needed. However, some off-grid solar systems equipped with battery storage can continue to operate during a power outage, providing electricity to the connected devices or storing excess energy for later use.

- Q:Is it possible for the everyday person to increase the efficiency of solar panels that they own? If so, how is it done?

- There are 3 (simple) ways to increase the efficiency of a solar panel at home - they all work by increasing the amount of light that falls onto it: . Have the solar panel track the sun throughout the day so that it always faces it; 2. Place a lens (larger than the panel) in front of the panel that focuses the light from the sun onto it. 3. Have mirrors around the panel than redirect light from themselves onto the solar panel. (e.g. imagine a satellite dish with the solar panel at the front and the dish being all mirrored.)

- Q:Also, what's the solar panel's rate of producing electricity?

- Solar thermal in commercial applications is more productive than natural gas, taking in consideration the sun must be out. the reason being is when natural gas is exposed to a heating element(boiler, hot water heater) it loses efficiency. lets say solar thermal can produce a therm of hot water, but that would equal .2 therms of natural gas using an 80 percent efficient boiler. solar being close to 95 percent efficient. No boiler can do that. now when the sun goes down, fossil fuel can beat electrically stored energy, not stored steam energy in a thermal plant for example. but that all depends on efficient steam generators.

- Q:Can solar panels be used in areas with high levels of pollution from industrial activities?

- Yes, solar panels can be used in areas with high levels of pollution from industrial activities. While pollution can have some impact on the efficiency of solar panels, they are still able to generate electricity even in polluted areas. Regular cleaning and maintenance of the panels may be required to ensure optimal performance. Additionally, installing solar panels in such areas can help offset some of the carbon emissions from industrial activities, contributing to a cleaner and more sustainable energy future.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

5W CNBM Monocrystalline Silicon Panel for Home Using

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 watt

- Supply Capability:

- 1000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords