5005 5052 5083 5754 Aluminum Tread Plate with Wide Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

l Production Introduction

1. Commodity: Factory manufacture low price high quality aluminum dimond plate sheets

2. Alloy No.: 050 1060 1100 3003 3004 3104 3005 3105 5005 5052 8011

3. Size: Thickness: 0.15-5.00mm(Tolorance±0.02mm)

Width:200-1600mm(Tolorance±1mm)

Length: 500-1500mm(Tolorance±1mm)

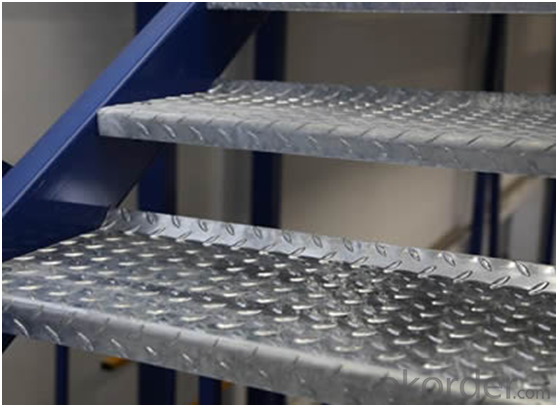

4. Application:

1) air plane, refrigerators ,audio equipment

2) building materials: ceilings, walls

3) telephones, digital cameras

4) plastic composite board, aluminum and plastic pipe

5.Month Capacity: 5000MT/Month

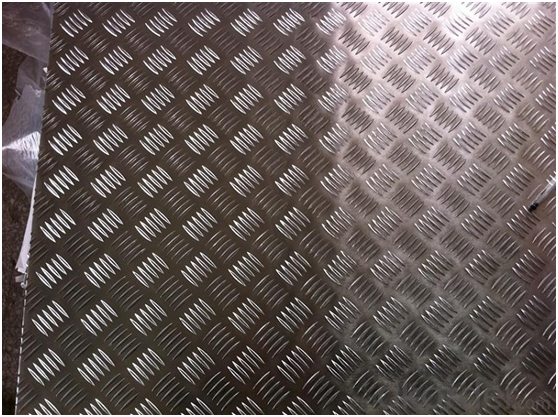

6.Pattern: 2 bars, 3 bars, 5 bars, diamond bar

l Packaging & Delivery

Packaging detail: First, plastic cloth; Second, Pearl Wool ; Third, wooden cases with dry agent ,without fumigation, wooden pallets

Delivery detail: Within 25days

l CNBM Images

l Product Images and Application

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q:How would you write the formula for aluminum sulfate and calcium chloride?

- Aluminium sulfate: Molecular formula Al2(SO4)3·16H2O Calcium chloride: Molecular formula CaCl2

- Q:Can aluminum sheets be coated with protective films?

- Yes, aluminum sheets can be coated with protective films. These films are typically made of materials such as polyethylene or polypropylene and are designed to provide a barrier against scratches, abrasions, and other forms of damage. The protective film is applied to the surface of the aluminum sheet, creating a layer that shields it from potential harm during handling, transportation, or processing. This coating process helps to maintain the integrity and appearance of the aluminum sheet, ensuring that it remains in excellent condition until it is ready for use.

- Q:The idea that you can adequately protect yourself from the Alien and government thought transmissions with a 'tin-foil / aluminum hat is just a myth. The correct and real thing to use is an aluminum construction site type of hard-hat. That is why the government and all major defense contractors wore aluminum hard-hats back in the 1950's. The plastic and fiber glass hard-hats that they use now is only because the Aliens got wise to the old aluminum hard-hat trick and outlawed them after the Aliens and their Illuminati minions took over after President Truman got out of office. Everyone knows that.So does any company anywhere in the world currently defy the Alien’s production ban on aluminum hard hats? Or is e-bay and garage sales the only source of aluminum construction site hard hats?

- are u serious? remember that aliens are demons. most of the time dreams are from the devil. so, don't believe in dreams. antichrist is pale with red eyes and wears gloves just like jigsaw from saw movie. but antichrist makes fire come down from the sky and moves at the speed of light 'cause demons (who appear as angels of light) carry him. mark of the beast is similar to the in time movie tattoo. when people stretch hands to receive small grey world passport, this 666 tattoo is given by lasers. chips and electronic tattoos are ways to track people to laser them. food stores will be set up to laser people. police will laser people on highways. those who go to be healed in ufo ships by demons will become spiritual zombies.

- Q:Can aluminum sheets be anodized in different finishes?

- Different finishes can be achieved when anodizing aluminum sheets. Anodizing, an electrochemical process, enhances the natural oxide layer on aluminum, increasing its thickness and durability. It is possible to customize this process to achieve clear, colored, or textured surfaces. The finish type relies on factors such as alloy composition, anodizing technique, and desired appearance. Due to their corrosion resistance, aesthetic appeal, and ability to maintain color over time, anodized aluminum sheets find extensive use in architecture, automotive, and electronics industries.

- Q:Can aluminum sheet be used for cookware?

- Yes, aluminum sheet can be used for cookware. Aluminum is a popular choice for cookware due to its excellent heat conductivity and lightweight properties. However, it is usually combined with other materials, such as stainless steel or non-stick coatings, to enhance its durability and prevent any potential reactions with certain foods.

- Q:Are aluminum sheets suitable for electronic enclosures?

- Certainly, aluminum sheets are a fitting choice for electronic enclosures. Aluminum is extensively employed in the production of these enclosures owing to its exceptional characteristics. It possesses the advantage of being both lightweight and sturdy, ensuring optimal protection for electronic components. Moreover, aluminum exhibits excellent thermal conductivity, effectively dissipating heat generated by electronic devices. Additionally, it is non-magnetic and non-sparking, thereby guaranteeing safety and preventing interference with electronic signals. Furthermore, aluminum can be easily molded, machined, and finished, providing opportunities for customization and aesthetic appeal. All in all, aluminum sheets offer a dependable and cost-efficient solution for electronic enclosures.

- Q:Can aluminum sheets be used for automotive applications?

- Yes, aluminum sheets can be used for automotive applications. Aluminum is a lightweight and corrosion-resistant material, making it ideal for various automotive components. It is commonly used in the construction of car bodies, engine parts, wheels, and other structural components. Aluminum sheets offer excellent strength-to-weight ratio, which helps improve fuel efficiency and overall performance of vehicles. Additionally, aluminum has good thermal conductivity, allowing for effective heat dissipation in automotive applications. Overall, the use of aluminum sheets in automotive manufacturing has become increasingly popular due to its numerous advantages.

- Q:What are the different types of alloys used in aluminum sheet?

- There are several different types of alloys used in aluminum sheet. Some of the most commonly used alloys include: 1. 3003 alloy: This alloy is known for its excellent resistance to corrosion and is often used in applications where exposure to moisture is a concern. It is also easy to form and weld, making it a popular choice for various structural components. 2. 5052 alloy: This alloy is highly corrosion-resistant and has good formability. It is often used in marine and automotive applications, as well as in architectural elements. 3. 6061 alloy: This alloy offers excellent strength and is commonly used in applications that require high structural integrity. It is often used in aerospace and marine industries, as well as in the construction of heavy-duty machinery. 4. 7075 alloy: This alloy is known for its high strength-to-weight ratio and is often used in aerospace and defense applications. It is also used in the manufacturing of bicycle frames, rock climbing equipment, and other high-performance applications. 5. 2024 alloy: This alloy is known for its high strength and excellent fatigue resistance. It is often used in aerospace applications, as well as in the production of structural components and fasteners. These are just a few examples of the many different types of alloys used in aluminum sheet. Each alloy has its own unique properties and advantages, making it suitable for specific applications and industries.

- Q:How does aluminum sheet perform in high-pressure applications?

- Due to its inherent properties, aluminum sheet is exceptionally effective in high-pressure applications. Its impressive strength-to-weight ratio makes it a suitable option for withstanding high-pressure environments. Additionally, aluminum exhibits excellent corrosion resistance, a crucial feature when dealing with high-pressure conditions that involve exposure to moisture or aggressive chemicals. Moreover, aluminum sheet is highly malleable, allowing it to be shaped and formed into various configurations to meet the specific requirements of high-pressure applications. Its flexibility enables it to endure the forces and stresses exerted during high-pressure processes without compromising its structural integrity. Furthermore, aluminum demonstrates good thermal conductivity, which aids in dissipating heat generated by high-pressure systems. This characteristic helps prevent overheating and ensures efficient operation. However, it is important to consider that the performance of aluminum sheet in high-pressure applications can be influenced by factors such as sheet thickness and alloy composition. Therefore, it is crucial to carefully select the appropriate grade and thickness of aluminum sheet based on the specific requirements and operating conditions of the high-pressure application. In conclusion, aluminum sheet is a dependable and efficient choice for high-pressure applications due to its strength, corrosion resistance, malleability, thermal conductivity, and overall performance under demanding conditions.

- Q:Can aluminum sheets be waterjet cut?

- Indeed, it is possible to employ waterjet cutting for aluminum sheets. By utilizing a combination of high-pressure water and an abrasive substance, waterjet cutting proves to be an adaptable approach in severing a range of materials, including aluminum and other metals. The efficacy of this technique in cutting aluminum stems from its ability to avoid heat generation, thereby preventing potential distortion or harm to the metal. Moreover, it ensures exceptional precision and accuracy, facilitating the effortless cutting of intricate shapes and designs. Consequently, waterjet cutting has become a prevalent practice in industries necessitating immaculate and precise cuts in aluminum sheets, such as aerospace, automotive, and manufacturing.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

5005 5052 5083 5754 Aluminum Tread Plate with Wide Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords