40Cr / 41Cr4 / 5140 alloy steel specifications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

40Cr / 41Cr4 / 5140 alloy steel specifications

Product Description:

1. Standards

GB 40Cr, 40X, ASTM 5140, BS 520M40, JIS SCR440, NF 42C4, DIN 41Cr4(1.7035)

2. Size:

Round steel bar: Dia. 8-10000mm

Flat steel bar: 10-600*205*1500mm

Length: <12m

3. Machine Capability

Tensile strength (N/mm2Mpa): >=835

Elongation %: >=10

Yield strength: >=540

Hardness: HBS<=179

Reduction of area: >=40%

4. Machinability

Long, gummy chips characterize this alloys machinability. It can be machined in the annealed condition, however condition H1150M will yield best results. Post machining solution treatment of parts will be required prior to final hardening if machining in this condition.

5. Welding

Successfully welded by common fusion and resistance methods, this alloy should not be joined by oxyacetylene welding. AWS E/ER630 filler metal is recommended if required.

6. Process:

EAF+LF+VD+ Forged+ Heat Treatment (Annealed, A Normalized, Q+T)

7. Inspection

100% Ultrasonic according to the test standards: SEP1921-84, GR. 3 CLASS C/C

Chemical Composition:

Chemical Composition(for reference only) (%) | |||||||

C | Si | Mn | Cr | Ni | P | S | Cu |

0.37~0.44 | 0.17~0.37 | 0.50~0.80 | 0.8~1.1 | ≤ 0.03 | ≤ 0.035 | ≤ 0.035 | ≤ 0.30 |

Application:

(1) Generally used for producing the important parts with high strength and good plastic.

(2) After nitrogen treatment, used for producing the important parts with special performance

requirements, such as shafts, gears, fasteners, bolt of large dia steamer etc.

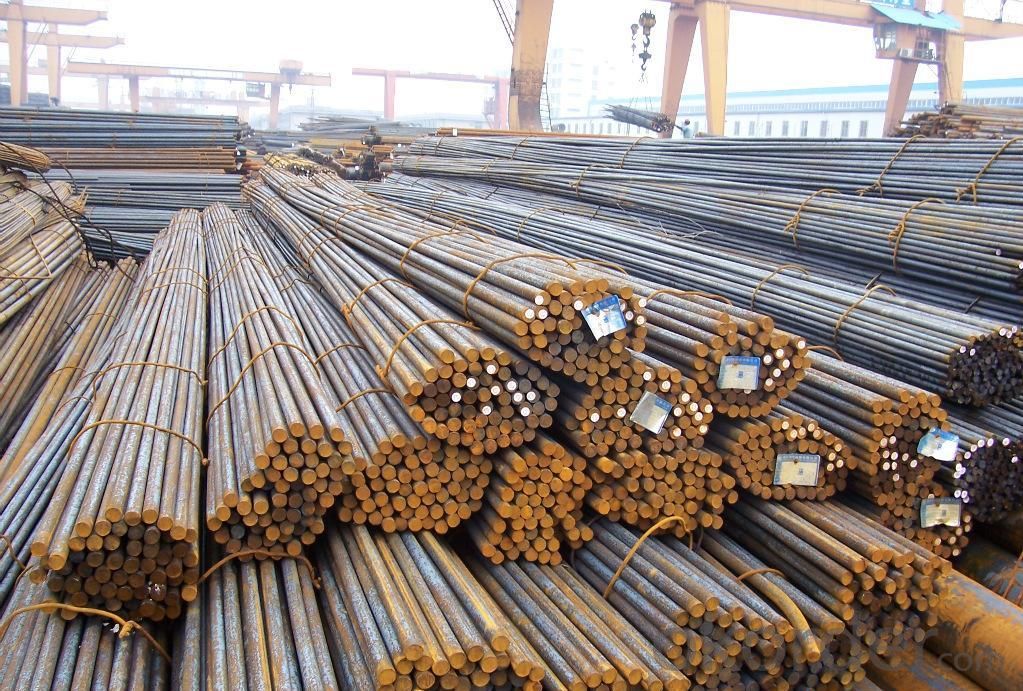

Product Show:

- Q:How does special steel perform in low-temperature environments?

- Special steel, also known as low-temperature steel, is specifically designed to perform exceptionally well in low-temperature environments. One of the key features of special steel is its ability to maintain its strength and toughness even at extremely low temperatures. This is crucial in industries such as oil and gas, where equipment and structures are exposed to extreme cold conditions. When exposed to low temperatures, regular steel tends to become brittle and lose its mechanical properties, making it prone to cracking and failure. However, special steel is formulated with specific alloying elements, such as nickel, chromium, and molybdenum, which enhance its low-temperature performance. These alloying elements help to prevent the formation of brittle phases, which allows the steel to retain its toughness and ductility even at sub-zero temperatures. Special steel is extensively used in cryogenic applications, where temperatures can reach as low as -196 degrees Celsius (-320 degrees Fahrenheit). It is commonly employed in the construction of cryogenic storage tanks, liquefied natural gas (LNG) carriers, and other components that come into contact with extremely cold fluids or gases. In low-temperature environments, special steel not only maintains its mechanical properties but also exhibits excellent resistance to corrosion. This is vital, as low temperatures can exacerbate corrosion issues in many materials. The corrosion resistance of special steel is attributed to its high nickel content, which forms a protective oxide layer that prevents the steel from corroding, even in harsh conditions. Overall, special steel is specifically engineered to withstand the challenges posed by low-temperature environments. Its ability to retain strength, toughness, and corrosion resistance makes it an ideal choice for various industries operating in extreme cold conditions.

- Q:How is precipitation-hardening steel used in the aerospace industry?

- Precipitation-hardening steel, also known as PH steel, is extensively used in the aerospace industry due to its exceptional strength-to-weight ratio and excellent corrosion resistance. This type of steel undergoes a heat treatment process that enables the formation of fine precipitates within its structure, resulting in improved mechanical properties. In aerospace applications, precipitation-hardening steel is commonly utilized for manufacturing critical components such as landing gear, engine parts, and structural elements. Its high strength and durability allow for the construction of lighter and more fuel-efficient aircraft, enhancing overall performance and safety in the aerospace sector.

- Q:What are the main elements in special steel alloys?

- The composition of special steel alloys varies depending on the specific type of alloy and its intended use. However, there are several shared elements that are often found in these alloys. These elements include: 1. Iron (Fe): Iron is the primary component of steel alloys, providing the foundation for their strength and durability. 2. Carbon (C): Carbon plays a crucial role in steel alloys, greatly impacting their hardness and strength. Different carbon levels can result in varying properties, such as high carbon steel for increased hardness or low carbon steel for improved flexibility. 3. Chromium (Cr): Steel alloys are frequently enriched with chromium to enhance their resistance to corrosion. It forms a protective layer on the alloy's surface, preventing oxidation and rusting. 4. Nickel (Ni): Nickel is commonly incorporated into special steel alloys to enhance their heat and corrosion resistance. It also contributes to improving the material's strength and toughness. 5. Manganese (Mn): Manganese is often added to steel alloys to improve their workability and machinability. It also enhances their strength and impact resistance. 6. Molybdenum (Mo): Special steel alloys often contain molybdenum to increase their strength, hardness, and ability to withstand high temperatures. It also improves their resistance to corrosion. 7. Vanadium (V): Vanadium is frequently used in steel alloys to enhance their strength, toughness, and heat resistance. It also aids in refining the alloy's grain structure, resulting in improved performance. These are just a few examples of the common elements found in special steel alloys. Depending on specific requirements and desired properties, other elements like tungsten, cobalt, copper, and titanium may also be present in varying proportions. The combination of these elements allows for the creation of specialized steel alloys with unique properties tailored for specific applications in industries such as aerospace, automotive, construction, and manufacturing.

- Q:Can special steel be coated?

- Yes, special steel can be coated. Coating special steel provides several benefits such as corrosion resistance, improved aesthetics, increased durability, and enhanced functionality. There are various coating materials and techniques available for special steel, including but not limited to electroplating, hot-dip galvanizing, powder coating, and ceramic coating. These coatings help protect the steel from environmental factors, chemical exposure, and wear and tear, thereby extending its lifespan and maintaining its performance. Additionally, coatings can also be customized to provide specific properties like non-stick surfaces, heat resistance, or anti-microbial properties, depending on the intended application of the special steel.

- Q:What are the main characteristics of pressure vessel steel forgings?

- Pressure vessel steel forgings possess several key features that render them suitable for utilization in pressure vessels. Firstly, these forgings are renowned for their exceptional strength and toughness. This attribute is of utmost importance as pressure vessels typically encounter significant internal pressure, necessitating steel capable of withstanding such force without deformation or rupture. Meticulous design and manufacturing ensure that the forgings possess the requisite strength and toughness to endure these pressures. Secondly, pressure vessel steel forgings exhibit remarkable resistance to corrosion. Given that pressure vessels frequently house corrosive fluids or gases, it becomes imperative for the steel employed in their construction to possess corrosion resistance. This feature guarantees the durability and dependability of the pressure vessel. The steel forgings are often crafted with specific alloying elements that enhance their resistance to corrosion. A further notable characteristic of pressure vessel steel forgings lies in their ability to retain their mechanical properties at elevated temperatures. Pressure vessels may be subjected to heightened temperatures due to the nature of the processes or fluids they contain. The forgings are designed to maintain their strength and toughness even in these high-temperature conditions, thereby ensuring the safety and reliability of the pressure vessel. Moreover, pressure vessel steel forgings typically undergo stringent quality control measures during their manufacturing process. This is essential to ensure that the forgings meet the prescribed standards and specifications for pressure vessel applications. The manufacturing process incorporates comprehensive inspections, testing, and documentation to guarantee compliance with the necessary quality and safety requirements. In summary, the primary characteristics of pressure vessel steel forgings encompass high strength and toughness, exceptional corrosion resistance, the ability to endure high temperatures, and stringent quality control measures. These attributes render pressure vessel steel forgings ideal for utilization in pressure vessels, providing the requisite strength, reliability, and safety demanded by such applications.

- Q:What are the different methods for improving the heat resistance of special steel?

- There are various techniques available to enhance the heat resistance of special steel. These techniques comprise: 1. Alloying: Enhancing the heat resistance of steel can be achieved by alloying it with specific elements. The addition of chromium, nickel, or molybdenum, for instance, significantly augments the steel's ability to withstand high temperatures. 2. Heat treatment: Heat treatment processes like annealing, quenching, and tempering can be employed to enhance the heat resistance of special steel. These processes refine the steel's microstructure and enhance its mechanical properties, including heat resistance. 3. Surface modification: The heat resistance of special steel can be improved by applying specialized coatings or surface treatments. Processes such as nitriding, carburizing, or ceramic coating create a protective layer on the steel's surface, preventing oxidation and enhancing its ability to withstand high temperatures. 4. Grain refinement: Heat resistance can be improved by controlling the grain size of the steel through processes like grain refinement or recrystallization. Smaller grain sizes reduce the diffusion of atoms within the material, making it more resistant to high temperatures. 5. Precipitation hardening: Precipitation hardening involves the formation of small particles within the steel matrix, strengthening the material and improving its resistance to heat. This technique requires a specific heat treatment process to enable the formation of these particles. 6. Controlled cooling: Optimizing the cooling process after heat treatment can also enhance the heat resistance of special steel. By controlling the cooling rate, the formation of unwanted phases or microstructural defects can be minimized, ensuring better heat resistance. 7. Material selection: Selecting the appropriate type of special steel with inherent high heat resistance properties is another method to improve heat resistance. Stainless steel, tool steel, or superalloys, for instance, are renowned for their excellent heat resistance and are often chosen for applications involving high temperatures. It is important to note that the choice of the suitable method or combination of methods for enhancing heat resistance depends on the specific requirements and limitations of the application.

- Q:How does special steel compare to other materials, such as aluminum or titanium?

- Special steel is known for its exceptional strength, durability, and resistance to wear and tear, making it superior to materials like aluminum or titanium in various applications. While aluminum is lightweight, it lacks the same level of strength and toughness as special steel. Titanium, on the other hand, offers comparable strength but is significantly more expensive. Special steel strikes a balance between strength, cost-effectiveness, and versatility, making it a preferred choice in many industries.

- Q:What is the composition of special steel?

- The composition of special steel can vary depending on its intended use and the specific properties required. However, in general, special steel is typically an alloy of iron and carbon, with additional elements added to enhance its strength, toughness, corrosion resistance, or other desired characteristics. Some common elements that can be found in special steel compositions include chromium, nickel, manganese, molybdenum, vanadium, tungsten, and cobalt. These alloying elements are carefully selected and added in specific amounts to achieve the desired mechanical, physical, and chemical properties of the steel. The composition of special steel can be tailored to meet specific industry requirements, such as for applications in aerospace, automotive, oil and gas, or construction.

- Q:What are the different quality control measures for special steel production?

- Some of the different quality control measures for special steel production include strict material sourcing and selection, thorough testing and inspection during the manufacturing process, adherence to specific industry standards and specifications, regular calibration and maintenance of equipment, proper handling and storage of finished products, and continuous monitoring and improvement of overall production processes.

- Q:How does special steel perform in magnetic applications?

- Special steel, also known as stainless steel, generally performs well in magnetic applications. However, it is important to note that not all types of stainless steel are magnetic. The magnetic properties of special steel depend on its composition and the presence of certain elements such as nickel, manganese, and chromium. Austenitic stainless steel, which is the most common type, is non-magnetic due to its high nickel content. This makes it ideal for applications where magnetic interference is undesirable, such as in sensitive electronic devices or medical equipment. On the other hand, ferritic and martensitic stainless steels, which have lower nickel content, are magnetic. These types of special steel are commonly used in applications where magnetic properties are required, such as in magnetic separators, transformers, and electric motors. It is worth mentioning that the magnetic strength of stainless steel is relatively weak compared to other magnetic materials like iron or nickel. Therefore, if a strong magnetic field is needed, alternative materials may be more suitable. Overall, special steel can perform well in magnetic applications depending on the specific type and composition. It is important to consider the desired magnetic properties and consult with experts or refer to material specifications to ensure the appropriate selection for a particular application.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

40Cr / 41Cr4 / 5140 alloy steel specifications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords