409 410 stainless steel sheetsCold rolled/hot rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Item specifice

Standard:

ASTM

Technique:

Cold Rolled

Shape:

Square,Round

Surface Treatment:

Coated

Steel Grade:

400 Series

Certification:

BV

Thickness:

2.5

Width:

1000

Length:

2000

Net Weight:

15

410 and 430 stainless steel sheet

1.Description of products

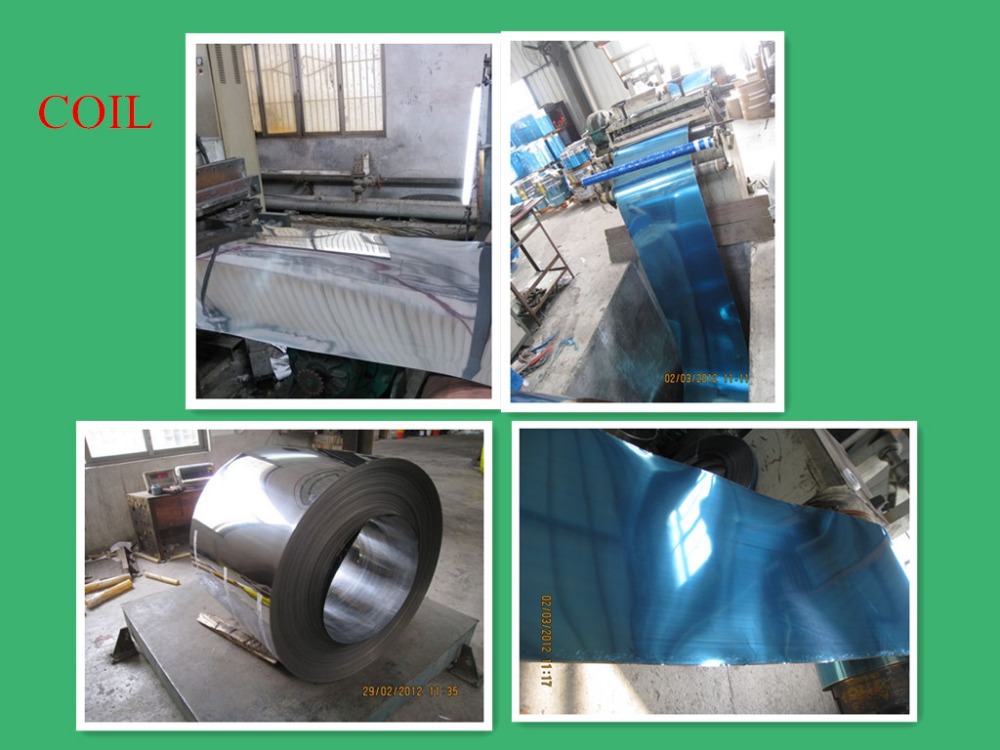

| Item: | Cold rolled stainless steel coil |

| Grade: | 410 430 |

| Standard: | JIS,AISI,ASTM,GB,DIN, |

| Thickness: | 0.16mm-2.0mm |

| Width: | max:1080mm |

| Place of Orgin: | Jieyang,China(Mainland) |

| Brand name: | baosteel , lisco,tisco,jisco |

| Type: | Plate,Coil,Circle,Sheet |

| Application: | Building ,household appliance. kitchen utensiles, industry and medical equipment,electric cooker etc. |

| Technical processing: | Cold rolled |

| Surface: | BA, 8K ,NO.4, mirror, hairline according to customer's request. |

| Certificate: | the third inspections |

| Port: | SHENZHEN, SHANTOU |

| Packaging Details: | Export standard package |

| Delivery Time: | About 10-30 days |

| Payment Terms: | T/T,Irrevocable L/C at sight,D/P |

| Supply Ability: | 2500Ton-3000Ton/per Month |

2. Products

Application

Building, elevator decoration,

household appliance. kitchen utensiles

6.Tips

If you are interested in our products,please tell us about the type,finish,size,thickness ,QTY and terms of shipment so that we can make an exact and favorable quotation for you.

Our philosophy:“Quality First”, advanced equipments together with experienced technicians ,hope we will have a chance to work for you,welcome to inquiry.

- Q:What are the bending limits of stainless steel sheets?

- The bending limits of stainless steel sheets are contingent upon several factors, including the stainless steel grade, sheet thickness, and the specific bending process employed. Stainless steel sheets are renowned for their exceptional strength and durability, enabling them to be bent to a certain degree without fracturing or breaking. As a general rule, stainless steel sheets can be bent to a radius that is at least twice the thickness of the sheet. For instance, a 1mm thick sheet can typically be bent to a minimum radius of 2mm. It is crucial to note, however, that this is merely a general guideline, and the actual bending limits may differ based on the particular stainless steel grade. Certain stainless steel grades, such as 304 and 316, possess higher yield strengths and greater resistance to deformation, rendering them suitable for more demanding bending applications. Thicker sheets also exhibit higher bending limits in comparison to thinner ones, as they possess more material to withstand the forces of bending. Moreover, it is important to mention that the chosen bending process can impact the bending limits of stainless steel sheets. Press brake bending and roll bending are commonly employed methods for bending stainless steel sheets. These processes employ distinct techniques and equipment, resulting in varying bending limits. To ascertain the exact bending limits for a specific stainless steel sheet grade and thickness, it is advisable to refer to the manufacturer's specifications or seek guidance from a professional metal fabricator. They possess the expertise and knowledge to provide precise information and guidance on the bending capabilities of stainless steel sheets tailored to your specific application.

- Q:Are stainless steel sheets resistant to caustic soda?

- Yes, stainless steel sheets are generally resistant to caustic soda. Caustic soda, also known as sodium hydroxide, is a highly corrosive substance, but stainless steel is known for its excellent corrosion resistance. Stainless steel contains chromium, which forms a protective oxide layer on the surface of the metal, preventing it from reacting with caustic soda. However, it is important to note that the exact resistance of stainless steel to caustic soda may vary depending on the grade or type of stainless steel. Therefore, it is always recommended to consult the specific material specifications or consult with a qualified professional to ensure the appropriate choice of stainless steel for specific applications involving caustic soda.

- Q:How do you clean and maintain stainless steel sheets?

- In order to clean and maintain stainless steel sheets, you will require a few basic supplies. These include a microfiber cloth or soft sponge, mild dish soap or a stainless steel cleaner, warm water, and a towel for drying. Begin by rinsing the stainless steel sheet with warm water to eliminate any loose dirt or grime. Next, gently scrub the surface of the stainless steel sheet using a small amount of mild dish soap applied to the microfiber cloth or sponge. It is important to avoid using abrasive materials or harsh chemicals as these can cause scratches or damage to the stainless steel. After cleaning, make sure to thoroughly rinse the sheet with warm water to remove any remaining soap residue. To prevent water spots, use a clean towel to dry the surface. Always remember to dry the stainless steel sheet after cleaning to prevent the formation of water spots or streaks. If there are stubborn stains or fingerprints that cannot be removed with soap and water, you can employ a stainless steel cleaner that is specifically designed for this purpose. Follow the instructions provided with the cleaner and use a soft cloth to apply it to the sheet. To avoid scratching the surface, wipe in the direction of the grain. Rinse thoroughly and dry as mentioned earlier. To maintain the shine and luster of stainless steel sheets, it is important to refrain from using abrasive cleaners, scouring pads, or steel wool as these can harm the surface. Additionally, avoid using cleaners that contain bleach or chlorine as they can cause discoloration. Regularly cleaning the stainless steel sheets is crucial to prevent the buildup of dirt, grease, or other contaminants that can result in corrosion. For most applications, a weekly cleaning routine should be sufficient, although in high-traffic or heavily used areas, more frequent cleaning may be necessary. In conclusion, the process of cleaning and maintaining stainless steel sheets involves gently scrubbing with mild dish soap or a stainless steel cleaner, rinsing with warm water, and ensuring thorough drying. By following these steps and avoiding abrasive materials, your stainless steel sheets will remain clean, shiny, and in optimal condition for years to come.

- Q:What are the main chemical constituents of stainless steel plates?

- Stainless steel not only refers to a stainless steel, but more than one hundred kinds of industrial stainless steel, the development of each kind of stainless steel in its specific application areas have good performance. The key to success is to find out what the purpose is, and then determine the correct type of steel. There are usually only six kinds of steel related to the application of building construction. They all contain 17 to 22% chromium, and better steel also contains nickel. The addition of molybdenum can further improve atmospheric corrosion, especially for atmospheric corrosion resistant chlorides.

- Q:Are stainless steel sheets resistant to pitting and crevice corrosion?

- Yes, stainless steel sheets are generally resistant to pitting and crevice corrosion. Stainless steel is known for its high corrosion resistance due to the presence of chromium, which forms a passive oxide layer on the surface of the material, protecting it from corrosion. This oxide layer acts as a barrier, preventing the penetration of corrosive substances that could cause pitting and crevice corrosion. However, it is important to note that the resistance to pitting and crevice corrosion can vary depending on the specific grade of stainless steel and the environmental conditions in which it is exposed. Some grades of stainless steel, such as 316 or 317, have enhanced resistance to these types of corrosion. In addition, certain aggressive environments, such as those with high chloride concentrations or acidic conditions, can still pose a risk to stainless steel and may require the use of more corrosion-resistant grades or additional protective measures. Overall, stainless steel sheets are highly resistant to pitting and crevice corrosion, but the specific grade and environmental factors should be considered for optimal performance.

- Q:What is the abrasion resistance of stainless steel sheets?

- Stainless steel sheets are widely acknowledged for their high level of abrasion resistance. They possess exceptional durability and hardness, which render them impervious to damage caused by friction or contact with abrasive substances. The extent of this abrasion resistance can differ, depending on factors such as the grade and finish of the stainless steel sheet, as well as the particular purpose it serves. Nonetheless, stainless steel sheets are renowned for their outstanding ability to withstand scratches, scuffs, and other types of abrasion, thereby making them a preferred option across diverse industries that prioritize longevity and durability.

- Q:Are stainless steel sheets suitable for outdoor furniture?

- Yes, stainless steel sheets are highly suitable for outdoor furniture. Stainless steel is known for its exceptional durability, resistance to corrosion, and ability to withstand various weather conditions. It also offers a sleek and modern appearance, making it a popular choice for outdoor furniture that can withstand the elements and maintain its aesthetic appeal.

- Q:What are the advantages of using stainless steel sheets in the aerospace industry?

- There are several advantages of using stainless steel sheets in the aerospace industry. Firstly, stainless steel is known for its exceptional strength and durability. It can withstand high temperatures and extreme conditions, making it ideal for aircraft components that require superior performance and longevity. This strength allows stainless steel sheets to resist corrosion, which is crucial in an industry where safety is of utmost importance. Secondly, stainless steel sheets offer excellent resistance to impact and fatigue. This is particularly vital in the aerospace industry, where components are subjected to constant vibrations and stress. Stainless steel can absorb these forces without compromising its structural integrity, ensuring the safety and reliability of the aircraft. Thirdly, stainless steel sheets have a high strength-to-weight ratio, making them lightweight yet strong. This is crucial in aviation, where reducing weight is a primary concern for fuel efficiency and overall performance. By using stainless steel sheets, aircraft manufacturers can achieve the desired strength without adding unnecessary weight, contributing to improved fuel economy and increased payload capacity. Furthermore, stainless steel sheets are highly versatile. They can be easily formed, welded, and machined into complex shapes and sizes, allowing for the production of intricate aerospace components. This versatility enables engineers to design and manufacture innovative aircraft parts, leading to improved aerodynamics, reduced drag, and enhanced overall performance. Lastly, stainless steel sheets have excellent heat resistance properties. They can withstand high temperatures without losing their strength or shape, making them suitable for applications that involve exposure to extreme heat, such as jet engines or exhaust systems. This heat resistance ensures the longevity and reliability of these critical components, contributing to the overall safety and efficiency of aircraft. In conclusion, the advantages of using stainless steel sheets in the aerospace industry are their exceptional strength and durability, resistance to impact and fatigue, high strength-to-weight ratio, versatility in manufacturing complex components, and excellent heat resistance properties. These qualities make stainless steel sheets an ideal choice for aircraft manufacturers, ensuring the safety, reliability, and efficiency of aerospace vehicles.

- Q:Can stainless steel sheets be used for backsplashes?

- Stainless steel sheets are indeed suitable for use as backsplashes. The reason why stainless steel is a popular option for this purpose is because it is durable, resistant to both heat and moisture, and requires minimal maintenance. Given that kitchen areas often experience high levels of heat and moisture, stainless steel is capable of withstanding these conditions, making it an ideal material for safeguarding walls behind stovetops and sinks. Moreover, stainless steel backsplashes can enhance the kitchen's appearance by providing a modern and sleek touch that complements various design styles. Additionally, cleaning stainless steel backsplashes is a breeze, as they can easily be wiped down using a damp cloth or cleaned with mild soap and water. All in all, stainless steel sheets are a practical and visually appealing choice for both residential and commercial backsplashes.

- Q:How do you calculate the bending radius for stainless steel sheets?

- In order to determine the bending radius for stainless steel sheets, several factors need to be taken into consideration. To begin with, the thickness of the stainless steel sheet must be determined. Thinner sheets necessitate smaller bending radii, whereas thicker sheets can accommodate larger radii. The type of stainless steel being used should also be identified. Various grades of stainless steel possess different levels of ductility, which impacts their ability to be bent. Higher ductility allows for smaller bending radii. Furthermore, the desired angle of the bend should be considered. The sharper the angle, the smaller the bending radius required. To calculate the bending radius, the following formula can be utilized: Bending Radius = (2 x Sheet Thickness) + (Bend Angle x Sheet Thickness) For instance, if a stainless steel sheet has a thickness of 0.5mm and a 90-degree bend is desired, the bending radius would be: Bending Radius = (2 x 0.5mm) + (90 x 0.5mm) = 1mm + 45mm = 46mm It is essential to note that this formula serves as a general guideline and may vary depending on the specific properties of the stainless steel being used. Consulting technical specifications or manufacturers' guidelines is always recommended for accurate bending radius calculations.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

409 410 stainless steel sheetsCold rolled/hot rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords