400/1000# Sharpening Whetstone of Double Sides Diamond Sharpener

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

400/1000# Sharpening Whetstone of Double Sides Diamond Sharpener

Diamond Stone Simple Introduction:

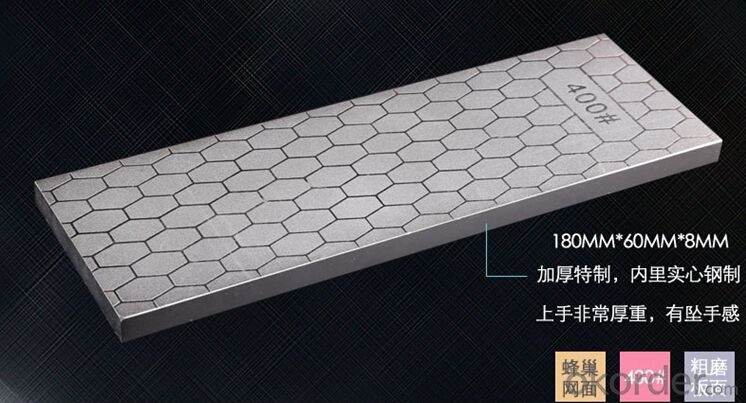

Name: 400 # / 1000 # double-sided high-grade grindstone

Size : 210*90*33mm

Stone Size:180x60x8mm

Weight: 795g

Package:Color box

Usage:Widely used in kitchen knives and garden tools, woodworking tools.

Package including:1x whetstone/1x plastic holder

Diamond Stone Description:

white fused alumina corundum material a high purity, white, with a high hardness, excellent self-sharpening, grinding power, high efficiency, is an acid corrosion, high temperature and other characteristics on both sides of the duplex Whetstone different granularity from the will of each particle size Whetstone different grinding effect, so a Whetstone has two grinding performance, affordable and versatile.

Diamond Stone Features:

1, high-grade corundum to ensure efficient and sharp sharpening effect.

2 sided sharpening design (400 # coarse 1000 # fine)

3, with plastic non-slip base to ensure sharpener security.

Product Show:

How to use:

First Whetstone placed soaked in water for about 5 minutes, and then on a stable platform, according to the blunt tool of the extent decided to adopt one or two steps:

Step one: 1000 # kibble for the blade or repair the damaged blade, suitable for a blunt tool.

Knife angle of 10 to 30 degrees the abrasive blade back and forth, with a small force in Whetstone surface. Grinding tools sharp can.

Tool sharpening general use after half a year the kibble once, also according to the specific circumstances.

Step Two: 3000 # finely ground, this is a necessary step, with the elimination of the burr on the knife-edge.

The use of smaller efforts, repair, smooth sharp blade edge can repeat the first step in sharpening method.

Under normal circumstances, it is recommended that once a week or daily use to keep your blade sharp.

2, tool wear, wipe with a damp cloth or rinse with water, then wipe dry. Cleanup Whetstone surface with a soft brush, put dry in a well-ventilated place

Note:

.Brothers to fully use the entire surface of the Whetstone, to keep Whetstone surface consistency.

.Use protection Whetstone avoid falls from a height.

.with the the sharpening oil use better.

.Sharpener and tool Do not put in easy reach of children to avoid accidents.

- Q:Sharpener good, advantages, disadvantages

- Is not good, it is recommended not to use, good knives are worn out, with the most primitive stone on the line

- Q:Do you have a Tupperware sharpener?

- Can you imagine corrugated cardboard.You want to fold the cardboard, along the texture is very easy to fold, vertical texture is very difficult.The blade is very easy to wear.And often, a knife, the knife is the best point.It's done.

- Q:Can a Zwilling knife be sharpened by another sharpener?

- Can be self grinding, blade angle to the original angle. I am self grinding, the effect is good, with the purpose of 3000 ruby stone.

- Q:Which kind of brand is good

- Locating the sharpener, can also be used with, and grinding after not easily scratch the hand, I hope to help you!

- Q:Stainless steel kitchen knife blunt how to profit? I sharpen the knife sharpener seems more blunt

- Stainless steel knife also has its special knife sharpener, most of the knife is put in the design of a good card slot back and forth grinding can be a. Of course, there are many kinds of knife grinder, if it is a good knife, a good horse with a good saddle, but also to buy a good sharpener, in accordance with the instructions to do, are very useful.There is a sharpener, the butcher used, the effect is also good, sharpening immediately becomes faster, but maintaining the sharpness of the relatively short time.Of course, the most traditional grindstone also can grind stainless steel knife, but involves a lot of technical problems, such as grinding angle, grindstone grain thickness, but will not get a knife is worn out, so if there is no point, or don't use.

- Q:Enrich the knife sharpener?

- The sharpener is characterized by use of the traditional single knife to double knife, sharpening method, angle changed efficiency, cutting the most blunt no more than half a minute, and make it very sharp, its efficiency is really incomparable, the knife sharpener is material with special material processing refined, long service life, simple operation and cheap, it is an indispensable good helper housewife. Compared with the traditional knife sharpener, modern sharpener has the advantages of high speed, simple operation, easy to carry, beautiful appearance and so on. In addition, the knife does not need to add water and oil and other liquids. Very safe and sanitary to use. There are many kinds of types is the sharpener necessary sharpener modern kitchen supplies, a fixed angle, there are flat and rodlike; grinding material, high performance ceramics, diamond hard alloy and stone; the product is different, the price difference is large. So how to choose their own sharpener and satisfactory? We can discuss from several aspects, for reference for everyone to choose: first, knives or tools and material hardness: if your tool or tool steel for the better or higher hardness, diamond knife sharpener, high performance ceramic sharpener and stone three optional; if your tool and tool material is also hard alloy material than steel, the choice of high performance ceramic diamond knife sharpener, sharpener, especially recommended is diamond sharpener (such as grinding ceramic knife or hard alloy cutting tools, diamond sharpener is the only choice). Second, single edge tool or double...

- Q:If there is no counter near the mill, you can grind it?

- Can be used sharpening stone, grinding time to use a little peanut oil or other oil can not use water! Force to light, knife and stone surface is about 45 degrees, a few light grinding on it. The sharpened edge is very smooth and sharp.

- Q:How do you use the sharpener? How to use

- Very simple! You can Baidu query: --- Fumin knife factory --- staff will be enthusiastic to answer for you. Hope to help you. Hope adoption.

- Q:Is it necessary to buy a Zwilling or a sharpener?

- Zwilling's knives are provided with a regular dealer counters free grinding service, consumers can be worn in the tool after the Zwilling counter free knife. But the cycle is very long, usually a month to two months.Zwilling counters also have a special knife sharpener and stick to sell, consumers can choose to buy their own knife at home.

- Q:Do you have a knife sharpener? Is there any good sharpener?

- Now there are many models such as Gangfeng sharpener, sharpener, knife fast three seconds

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

400/1000# Sharpening Whetstone of Double Sides Diamond Sharpener

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords