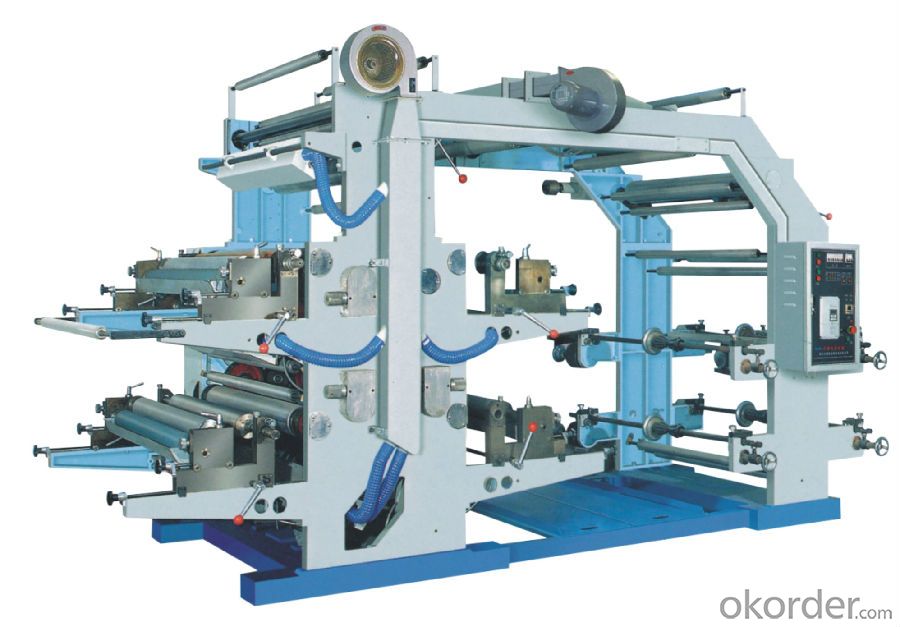

4 Colors High Speed Flexo Printing Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

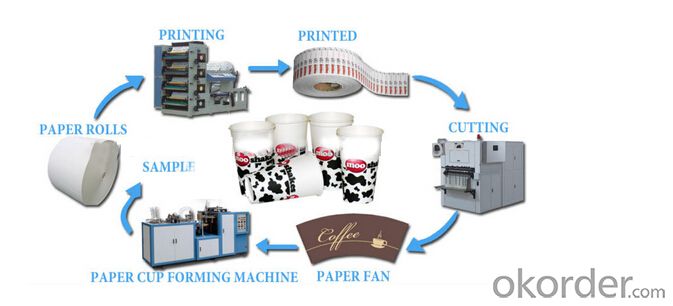

Product introduction

This machine is suitable for printing such packing materials as polyethylene,polypropylene plastic bag,cellophane and roll paper,etc.And it is a kind of ideal printing equipment for producing paper packing bag for food ,supermarket handbag and clothes bag,etc.

Station for 5-color flexo printing machine:

1.One mounting machine

2.One anilox roller for each group (lpi is optional, made in shanghai)

3.Three sets printing rollers (3*5=15)

4.Printing both sides at the same time (with turn bar)

5.With the lamination station

6.One unwinding tension controller (Mitsubishi Japan)

7.One rewinding tension controller

8.One rotary die cutting station

9. One rotary sheeting station

Main technical parameter

Model | CMAX 320-5D |

Printing speed | 60m/min |

Printing color | 5colors |

Max. Web width | 320mm |

Max. Printing width | 310mm |

Max. Putting diameter | 600mm |

Max. Winding diameter | 550mm |

Printing girth | 175-580mm |

Precision of chromatography | ±0.10mm |

Dimensions | 3100*1100*2300(mm) |

Machine weight | About 2300kg |

Product show

RFQ:

1, Q: How about the after service?

A: We have a strong team, special for after service. We can arrange engineers to do service for you.

2, Q: Are you factory or trading company?

A: We are a factory in this field nearly 20 years (Formally named Ruian Donghai Printing Machinery Co.,Ltd.).

3, Q: Where is your factory located? How can I visit there?

A:Our factory is located in Beijing City, China, You can fly to Beijing airport directly.

4, Q:How does your factory do regarding quality control?

A:Quality is priority. We always attach great importance to quality controlling from the beginning.

5, Q: why choose CNBM Machinery?

A: We are one of leader in this field(in China). Our quality products and service have enabled us to expand our market from china to more than 60 countries.

- Q:What is the direction of the printing press?

- For example: in the original main type on the basis of the same type of unit together, can make single-sided, monochrome printing into a single-sided, multi-color printing, but also make double-sided, monochrome printing into a single,

- Q:What is a screen printing machine?

- Production of wire mesh material in addition to silk, but also available nylon wire, copper wire, wire or stainless steel wire

- Q:What is the printing machine?

- Printing machinery is the printing press, binding machines, platesetter and other mechanical equipment and other auxiliary machinery and equipment collectively.

- Q:What is gravure printing machine?

- Then, the ink layer on the surface of the printing plate is scraped off, the raised portion is formed as a blank, and the recessed portion fills the ink, and the deeper the ink layer is deeper.

- Q:What is a lithographic printer?

- Lithographic printing press has been widely used electronic computer control device, technically increasingly advanced.

- Q:What is the historical development of presses?

- World printing machinery since the 20th century, 80 years has made great development. For more than 20 years, the development of printing machinery has gone through three stages.

- Q:What is the development of printing machinery?

- China's printing machinery manufacturing industry production and demand and investment strategic planning analysis report [1] data show that China's printing machinery industry above the scale of enterprises have 381, the annual sales income of 20.35 billion yuan, an increase of 18.40%;

- Q:What is the basic classification of printing machinery?

- Fourth, in accordance with the printing format is divided into "eight open printing presses, four open printing press, off the printing press, full Zhang printing press, super full Zhang printing press;

- Q:What is a letterpress printing machine?

- The letterpress printing press is the oldest digital press for printing presses, and the graphic part of the plate surface is raised and the blank part is concave.

- Q:What is the application of the press?

- The speed of the motor is fixed, but in the actual use of the process, sometimes to lower or higher speed operation, so the frequency conversion is very necessary.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

4 Colors High Speed Flexo Printing Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords