4.0 Heat Tempered Glass Anti-fire Glass Fire Place Fireproof Glass For Fireplaces

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 carton

- Supply Capability:

- 10000 carton/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

4.0 Heat Tempered Glass Anti-fire Glass Fire Place Fireproof Glass For Fireplaces

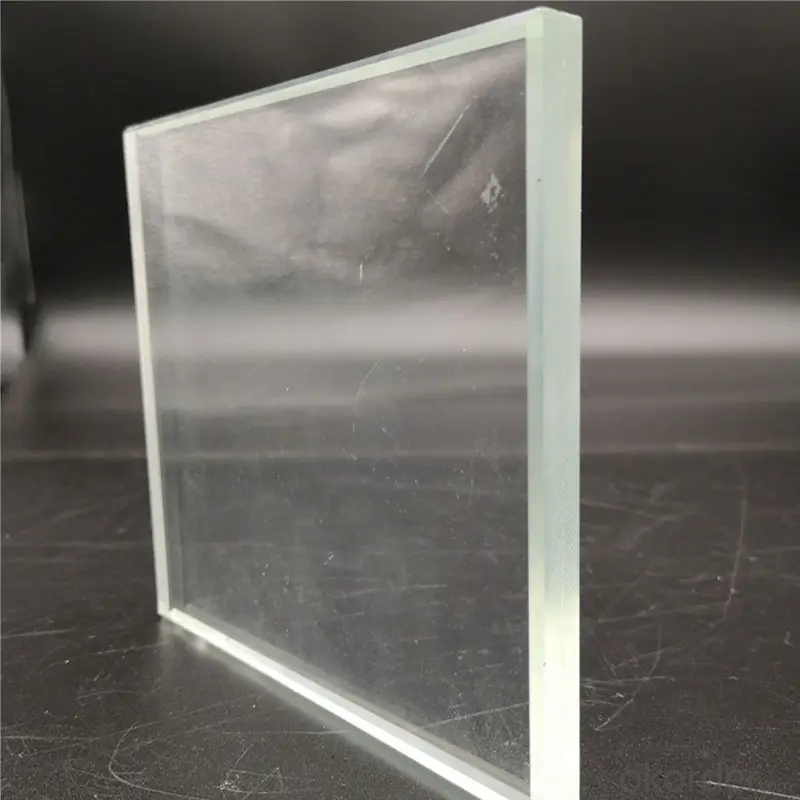

Fireproof Glass alway use microcrystalline glass, also called ceramic glass is made of a special glass-ceramic, is an extremely heat-resistant, transparent glass ceramic which can be produced in a wide variety of shapes and sizes to meet your specific needs.

Fireproof Glass Advantages:

Our top quality fire-proof glass is widely used for luxury hotel, theater, exhibition hall, airports, gymnasium,hospital,

commercial building and other public building. And all our fire-proof glass has the following features:

(1) Fire-resistance: fire-proof glass can keep down the spread of fire effectively;

(2) Safety: If it is broken, it usually breaks into relatively small pieces, which are less likely to cause serious injury;

(3) High temperature resistance:Fire-proof glass can endure more than 300°C temperature

Bullet-proof glass

Layered with glass,PVB and polycarbonate,the kinetic energy of the bullet is convered into heat by the glass and interlayer.The Bullet-proof glass is widely used for museum artifacts,banks bulletproof,showcase,villa doors and windows etc.

Thickness:3-19mm(can be customized)

Max Size:4800*2440mm

Product Property:Tempered,Laminated

The factory mainly produces

Borosilicate 4.0 fireproof glass is widely used in household appliances, electronics, instrumentation, optics, aerospace and other fields.

Borosilicate 4.0 fireproof glass has good thermal properties, mechanical properties, optical properties and ultra-high chemical stability. The visible light transmittance is 92%, and the high light transmittance in the near-infrared and ultraviolet bands exceeds 90%. The sign of fluorescence is far lower than that of soda lime glass.

1)Water resistance (International Organization for Standardization 719): Grade A

2)Acid resistance (International Organization for Standardization 195): Grade A

3)Alkali resistance (International Organization for Standardization 695): Grade B

The thickness of the glass ranges from 2.5mm to 15mm, and the maximum size can reach 4800mm×2440mm.

Specification:

Type | fireproof glass |

Thickness can choose | 3-4.5mm |

Glass edging | Flat polish, pencil polish, miter, bevel, O.G. bull nose and etc |

Features | Fireplace glass |

Certificate for factory | ISO 9001 2008, ISO 14001 2004 |

Color | Clear, Ultra Clear, Various Green, Blue, Gray, Brown |

Shape | bent, curved and flat |

Package | Pckage with foam board, cardboard boxes, wooden crates,also can pcak according to cusomer's requirement |

Application | Door for fireplace and stove |

OUR PACKING

Wooden crate, carton box, plastic film, customized, all packing can be fulfilled at Glass.

professional and experienced working stuff, all packing and loading is guaranteed to be strong and seaworthy to reduce the breakage rate to as low as possible.

Package Type:

1)Inter package is paper or plastic between two sheets;

2)Seaworthy wooden crates;

3) Iron belt for consolidation for insulated glass

Company introduction

CNBM is a subsidiary of China National Building Materials Group Co., LTD., one of the World's top 500 enterprises CNBM line adopts oxygen combustion + electric boosting technology + platinum system technology with completely independent intellectual property rights. It is equipped with a melting furnace, tin bath, annealing furnace, and cold end cutting system suitable for the production of borosilicate glass. There are well-known international brands suitable for cutting and edging of borosilicate glass in Italy, and the latest tempering furnace in Finland. The company mainly produces borosilicate 3.3 heat-resistant glass and borosilicate 4.0 fire-resistant glass.

FAQ

Q:How to get a quotation?

A: we need to get specific details, such as size, color, thickness, quantity, edge,etc.

Q: Can you do the production as customized?

A: Yes, we have a professional technique team, we could produce the glass depends on your requirements.

Q: What the your glass package ? Are they safe ?

A: Wooden Crates Worthy for Ocean and Land Carriage .The crates will be very strong and every loading worker has 12years packed,

loading and fixation crates with container experience. And we send the loading pictures for you after we loading .

Q:. What is your minimum order quantity?

A:Our MOQ is one full 20 feet container.

Products of different sizes and specifications could be mixed in one container.

Q: Can you supply a free samples ?

A: yes, if you want us to provide big size sample according to your requirements, you should pay the cost of production.

- Q:Why do the cabinets in the bathroom use fireproof board material, the bathroom is easy to fire?

- Because the fire board has: waterproof performance. The concept of the fire board is easy to confuse with the professional name. In fact, the fireproof plate we talk about is the fireproof sheet (for example, on the cupboard). It is made of fireproof board (or fire board veneer) and substrate MDF or particleboard) by hot sol high temperature and pressure made by paste. Fireproof board (fire board veneer), also known as fire board, formerly known as thermosetting resin impregnated paper high pressure decorative laminated board, abbreviated as HPL, is a surface decoration with refractory building materials, a rich surface color, pattern and special Physical properties and ease of processing, widely used in interior decoration of the surface material. It is impregnated with phenolic resin for the core (bottom) layer and the amino resin (mainly melamine resin) impregnated paper for the surface layer by heating and bonding at a pressure of not less than 5MPa, the outer layer of one or two A decorative color or pattern. Fire board / fire board is the base paper after melamine resin and phenolic resin processing, the main physical properties are shown by the resin characteristics. Melamine resin thermosetting after a good gloss, good transparency, high surface hardness, wear resistance, high temperature, impact resistance, surface pores are not easy to be pollution, chemical resistance, water resistance, solvent resistance, Such as excellent performance, mechanical strength, electrical insulation, good arc resistance and easy aging. Phenolic resin resin after heat curing and heat and hard and other properties. After the combination of two resins, fire board / fire board both the performance of both.

- Q:What are the general differences? The The

- LS said the two are modified plastic, that is, the material may itself is not good flame retardant, but by adding flame retardant, you can make the material to achieve a certain level of flame retardant, in other words, that is, most of the material added Flame retardants have flame retardant properties, but this should not be the answer to the landlord want it fundamentally speaking, the flame retardant test material is to see the material off the fire after the extinguishing time, or material burning time, according to material Different, different sizes, different testing methods, of course, there are many natural flame retardant materials, such as PVC (PVC) without adding flame retardant, it is extinguished from the fire. (PEEK), polyetherimide (PEI), polyphenylene sulfide (PPS), polyphenylene sulfone (PPSU), polyphenylene sulfide (PPS) , Polyether sulfone (PES), polyvinylidene fluoride (PVDF) and liquid crystal polymer (LCP) and so on. PBT itself is not very good flame retardant, halogen-free flame retardant can also be modified, the so-called halogen-free flame retardant or halogen-containing flame retardant, it means that the use of the taste is a bit of fat, Flame retardant, halogen-containing combustion in the general produce toxic gases, but the flame retardant effect is very good, the price is low. As for how you mention the difference, do not know what you want to distinguish, I feel you are not like to ask how the difference between the plastic resistance is not flame retardant, the general is a direct test friends, fundamentally speaking, and molecular structure has a great relationship, such as PVC (Polyvinyl chloride) containing Cl, burning produce HCl, so the flame retardant effect is good, but the HCl toxic, look at the polymer aspects of the bar, I hope to help you

- Q:Pipeline insulation materials, which are generally several types of fire protection

- Building materials fire rating of the following four grades: A: non-flammable Building materials: almost no combustion. B1 level: flame retardant building materials: a good flame retardant effect, in the air case of fire or high temperature is not easy to fire, not easy to spread, and in the open fire will immediately stop burning. B2 grade: flammable building materials: a certain role in the fire, in the air in case of fire or high temperature will immediately fire burning, easy to lead to fire spread, such as wood structure housing. B3: Flammable Building materials: no flame retardant effect, easy to burn, fire a great danger.

- Q:Does the ceiling need to brush fire paint?

- The use of the roof is not flammable materials, in accordance with the construction of Gong Yu Gui Yi Yi see the color of the design of fire code is not brush fire retardant paint, but the master's roof must be painted fire retardant paint, a fire 1.5h, two fire 1h. If it is needed with wooden keel

- Q:A1 grade external wall insulation materials which

- Rock wool fire isolation zone "rock wool board" mainly by the pendulum production of hydrophobic rock wool board for the thermal insulation material Hu Dan high citrus spong corpse for the construction, the use of sticky and nail combination process and the base wall Body connection fixed, and by the surface of the mortar and reinforced with fiberglass mesh made of composite layer and decorative mortar finishes or paint composition of the A-class non-combustible building energy-saving insulation system. Rock wool board exterior insulation system, low thermal conductivity, good air permeability, high level of combustion performance advantages, can be applied to the new, expansion, alteration of residential buildings and public buildings external wall of energy-saving insulation works, including external insulation, Non-transparent curtain wall insulation and EPS insulation system of the fire isolation zone. The system is the European top insulation brand-Barumit (Fort Mitter) launched, access to the European Technology Certification (ETA).

- Q:How is the distinction between fire grade?

- How is the distinction between fire grade?...

- Q:What are the materials for the kitchen ceiling that meet the fire protection requirements?

- In all the interior decoration of the fire design, the ceiling of the fire design in the most important position. This is because the fire is burning up the fire, the ceiling first and directly accept the fire test; the same time, there is a direct impact on the evacuation, will directly constitute a threat to the safety of evacuated personnel. Therefore, in the interior ceiling decoration design, should give full consideration to its fire problem. "Fire protection within the building design fire code" on the different civil buildings of indoor ceiling material fire performance has a detailed requirement. Ceiling (prungroof), refers to the roof of the living environment of the decoration. The ceiling is an important sub-division of the building decoration project. The ceiling has the function of insulation, insulation, sound insulation and sound absorption. It is also a hidden layer of electrical, ventilation and air conditioning, communication and fire prevention, alarm pipeline equipment and so on. The ceiling in the whole room decoration occupies a very important position on the top of the room for the appropriate decoration, not only to beautify the indoor environment, but also create a colorful interior space art image. In the choice of ceiling decoration materials and design programs, to follow the two materials, solid, safe, and beautiful, practical principles.

- Q:Ventilation duct fan outsourcing fireproof material specifically what

- 8.5.6 Ventilation, air conditioning system piping, etc., should be made of non-burning materials, but contact with corrosive media duct and flexible joints, can be made of refractory materials. 8.5.7 Insulation materials, silencers and adhesives for pipes and equipment shall be non-combustible materials or refractory materials. Through the firewall and deformation of the duct on both sides of the 2.00m should be used within the scope of non-combustion materials and binders. 8.5.8 When the electric heater is installed in the duct, the fan shall be interlocked with the electric heater. Electric heater before and after the 800mm within the duct and through the fire and other places with easy fire parts of the pipeline, must use non-combustible insulation materials

- Q:Decorative materials Fireproof paint three degrees What does it mean

- Paint the number of Road, that is, times, three degrees, that is, three or three times

- Q:What kind of good insulation materials for cold storage?

- High-end with a vacuum insulation board composite cold storage board, A-class fire, good insulation effect.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

4.0 Heat Tempered Glass Anti-fire Glass Fire Place Fireproof Glass For Fireplaces

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 carton

- Supply Capability:

- 10000 carton/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products