33016 Tapered Roller Bearigs Single Row Bearing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

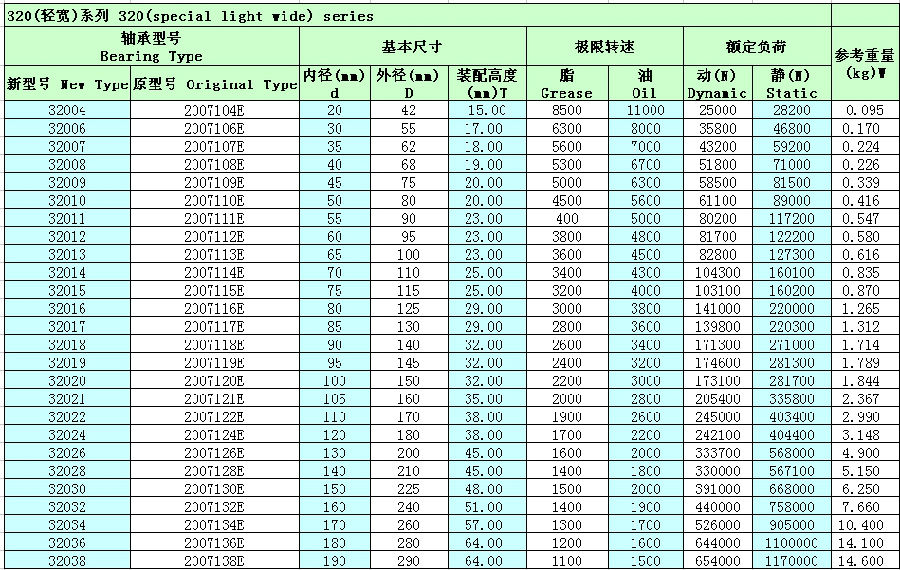

Specificatioin of Taperder Roller Bearings:

The tapered roller bearing is to bear the combination of radial and axial load but mainly afford radial load. The loading capibility is determined by the raceway angle of outer ring, the larger angle afford larger load. This kind of bearings can be seperated and it can be divided into single-row and double-row tapered roller bearings by the number of columns. The clearance for single-row tapered roller bearing should be adjusted by the customers when installation. For the double-row tapered roller bearings,the clearance has already set by the manufacture before ex-factory. Tapered roller bearing has taper shaped inner ring and outer ring raceway,and the roller elements arrange between them. All projection lines from the surface of rollers meet at the same point on bearing axis. This design makes tapered roller bearings particular suitable for combined (axial and radial) loads.The axial loading capacity is determined by the contacting angle α, the bigger angle for α, the larger axial loading capacity is. Tapered roller bearing is usually a seperated bearing, that is,the inner ring assembly including roller and cages, is seperated installed with the cup.

Taper roller bearings are mainly used for radial and axial joint load with radial load as main subject. Axial load capacity relies on raceway angle of outer ring: the bigger the angle is, the bigger the bearing capacity is. Outer ring can be separated and can be easily assembled. During installing and using process, axial clearance and radial clearance and radial clearance can be adjusted and pre-interference installation can be allowed.

Product application:

In many applications tapered roller bearings are used in back-to-back pairs so that axial forces can be supported equally in either direction.

- car and vehicle wheel

- mining equipment

- moderate speed

- engine motors

- axle systems

- construction

- agriculture

- reducers

- gear box

- Q:Can tapered roller bearings be installed in a vertical direction? In a vertical direction rather than in a horizontal direction..

- Whether horizontal mounting or vertical installation, the axial direction is axial and radial is radial

- Q:What are the general uses of tapered roller bearings?

- Widely used in machinery and equipment, water conservancy and Hydropower Engineering, railway, automobile, steel, textile, packaging, medicine, metallurgy, mining, petroleum, electric power, papermaking, computer, motor, sports equipment, office equipment, instrumentation, auto motor, precision instruments and other fields

- Q:Is the tapered roller bearing so correct?

- Tapered roller bearingTapered roller bearings are designed for the inner ring, outer ring raceway and roller cone vertex on the central axis of the bearing, radial load acting on the bearing, axial force is generated. Therefore, it is necessary to use the 2 bearings for use, or as double pairs of bearings, double row bearings. Combination and double row tapered roller bearings, when radial loads act on tapered roller bearings

- Q:Why is the cage of tapered roller bearings loose?

- You can come up with the relevant standards, must belong to the bearing standard parts, as long as you meet the standard requirements of the bearing can be spread!

- Q:Tapered roller bearing suffix code YA2 stands for what does that mean?

- Mr. Liu five love reading, "gladly forget to eat" every knowing; ong drinking is not wine, but for mountains and rivers ". So Mr. Qian Zhongshu proposed" all happiness enjoy all belong to the spirit of "the world as truth, but think, feel spiritual satisfaction is also flawed, sometimes even the feeble.

- Q:How does the roller of tapered roller bearings fit in?

- Tapered roller bearings are made up of outer rings, inner rings, rollers, and cages. The outer ring is a single body, and the inner ring, roller and cage are assembled together. They are called inner components. Tapered roller bearings belong to separable bearings, and when installed, the two components (inner and outer rings) can be fitted together.

- Q:The installation of tapered roller bearings

- 2, when installed, the direction of the roller tilt there is a regulation? Must be the same as the following picture?:You say that the direction of the tilt is actually the same direction of the bearings, the installation of the problem to different ah!

- Q:The roller of tapered roller bearings is cylindrical or cylindrical body? Why roller drawing method of drawing section for the rectangular (here I want to add: I have seen the N version, some of the paintings is rectangular, trapezoidal and some paintings, 2 versions, a few of my book is that the proportion is A/2 the roller projection) it indicates that the real roller should be a cylinder or a cylindrical body roller is... What master?

- Cylindrical rollers are used only when the raceway is a cylinder.Mechanical drawing clearly stipulates the simplified drawing method of tapered roller bearings. Rollers are drawn into cylinders.

- Q:There is a slot in the inner ring of tapered roller bearings, right? Is the roller in the slot?

- Yes.AskIs there a gap between the roller and the slot when the roller is placed in the slot?Chasing the answerNo

- Q:What is the 30207 judgment coefficient e of tapered roller bearings?

- What do you need to see for yourself?:Tapered roller bearings: 30207Internal diameter d:35mmOutside diameter D:72mmInner ring height B:17mmOuter ring height C:15mmTotal height (assembly height) T: 18.25mm

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

33016 Tapered Roller Bearigs Single Row Bearing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords