316TI Stainless Steel Round Bar price per kg for medical equipment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Specifications

Name:Stainless Steel Round Bar

1) Standard:ASTM

2) Material: Stainless steel

3) Grade: 201,202,304,304L,316,316L,321...

4) Shape:round bar

5) Surface: Black, Hairline, Bright, Polished

6) Finish: Cold drawn, Hot rolled

7) Diameter: 4-300mm

8) Length: 1000mm-12000mm

9) Payment terms: T/T 30%payment in advance, 70% T/T before shipment or by L/C

10) Packing: Export sea worthy package

11) Delivery time: Within 30 days after receiving 30%T/T of deposit or L/C

Name | Stainless Steel Round Bar for construction |

Standard | ASTM |

Material | Stainless steel |

Grade | 201,202,304,304L,316,316L,321... |

Surface finish | Black, Hairline, Bright, Polished |

Shape | stainless steel Round bar |

Finish | Cold drawn, Hot rolled |

Diameter | 4-300mm |

Length | 1000mm-12000mm |

Packing | Export sea worthy package |

Delivery | Within 30 days after receiving 30%T/T of deposit or L/C |

MOQ | 1MT |

Price terms | FOB, CFR, CIF |

Payment terms | T/T, L/C |

Application | Stainless Steel Round Bar applies to construction,Petroleum & chemical industries, construction field, machinery and hardware fields, food processing and medical industry, high or low temperature resistance, electricity industries, etc. |

Quality control: | a)Mill Test Certificate is supplied with shipment. b)Third party inspection is highly welcomed. |

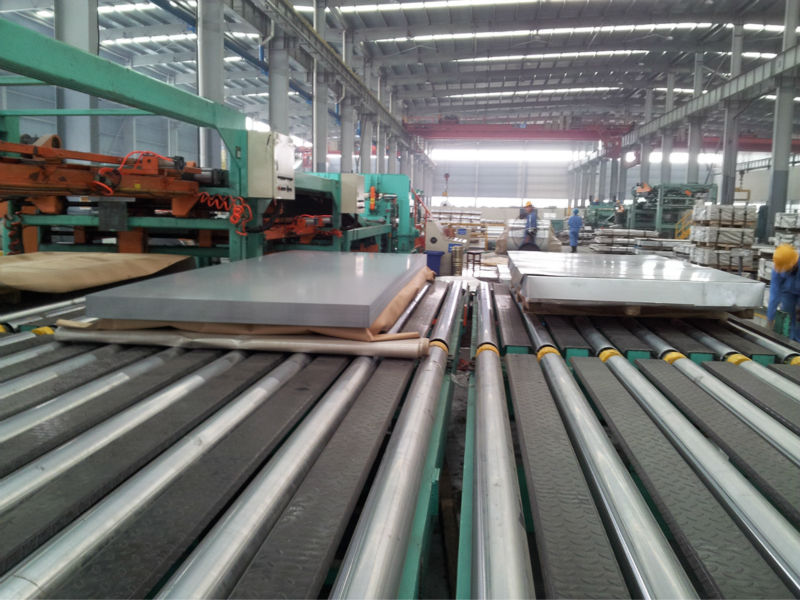

Workshop

Packaging & Shipping

- Q:What are the different heat treatment processes for stainless steel bars?

- Some of the different heat treatment processes for stainless steel bars include annealing, solution annealing, quenching and tempering, and precipitation hardening.

- Q:Can stainless steel bars be used in the transportation aftermarket?

- Indeed, the transportation aftermarket can make use of stainless steel bars. With their exceptional corrosion resistance, stainless steel proves to be a flexible and long-lasting material, rendering it the perfect option for applications within the transportation sector. In fact, stainless steel bars can be employed in an assortment of aftermarket components, including but not limited to truck accessories, trailer parts, railings, and brackets. These bars not only provide robustness and stability but also endure harsh environmental conditions, such as moisture, chemicals, and extreme temperatures. Moreover, stainless steel bars possess aesthetic appeal and necessitate minimal upkeep, ultimately making them a cost-effective solution for the transportation aftermarket.

- Q:Are stainless steel bars suitable for manufacturing tools?

- Yes, stainless steel bars are highly suitable for manufacturing tools due to their high strength, corrosion resistance, and durability. Stainless steel bars can withstand heavy loads, retain their shape and hardness even in extreme temperatures, and are resistant to rust and corrosion. These properties make stainless steel bars an excellent choice for various tool manufacturing applications, ensuring long-lasting and reliable tools.

- Q:What's the price of 202 stainless steel round bar?

- The basic alloying elements of stainless steel, as well as nickel, molybdenum, titanium, niobium, copper, nitrogen and so on, to meet the various requirements for the use of stainless steel structure and performance. Stainless steel is easy to chloride corrosion, because chromium nickel chloride is collocated elements, elements will be collocated to form stainless steel corrosion exchange assimilation.

- Q:Can stainless steel bars be polished to a mirror finish?

- Stainless steel bars possess the ability to attain a mirror finish when polished. Attaining a mirror finish on stainless steel bars involves a series of steps. Initially, imperfections or scratches on the surface are eliminated by sanding the bars with increasingly finer abrasive material. Once the surface becomes smooth, a polishing compound is utilized to further refine and enhance the shine of the surface. Subsequently, the bars are buffed with a soft cloth or polishing wheel to generate a reflective, mirror-like finish. By implementing the appropriate equipment and techniques, stainless steel bars can be polished to a remarkable level of shine, ultimately achieving a mirror finish.

- Q:Are stainless steel bars easy to clean and maintain?

- Yes, stainless steel bars are easy to clean and maintain. They have a smooth surface that resists stains and corrosion, making them simple to wipe clean. Additionally, stainless steel has inherent durability and can withstand harsh cleaning agents without losing its shine or structural integrity. Regular maintenance involves routine cleaning and occasional polishing to keep the bars looking their best.

- Q:Can stainless steel bars be used in the pulp and paper industry?

- Indeed, the pulp and paper industry can utilize stainless steel bars. Renowned for its resistance to corrosion, stainless steel proves to be a fitting material for a plethora of applications within industries commonly exposed to chemicals, liquids, and high temperatures. Within the realm of the pulp and paper industry, stainless steel bars serve various purposes, including the fabrication of machinery components, the construction of tanks and vessels, and the design of conveyor systems. The unparalleled strength and durability of stainless steel render it an ideal choice for withstanding the demanding conditions and harsh environments typically encountered in pulp and paper mills. Furthermore, stainless steel's hygienic properties and ease of cleaning make it highly suitable for industries that impose stringent sanitation standards, guaranteeing the production of pristine and first-rate paper products.

- Q:Can stainless steel bars be mirror polished?

- Indeed, it is possible to achieve a mirror-polished appearance on stainless steel bars. The process of mirror polishing involves meticulously polishing the surface of stainless steel until it attains a remarkably reflective and lustrous finish. This is accomplished by employing increasingly finer polishing abrasives and buffing compounds to eliminate any flaws and establish a flawlessly smooth and reflective surface. By undergoing mirror polishing, stainless steel bars are not only enhanced aesthetically but also fortified against corrosion, thus providing an additional layer of protection.

- Q:Can stainless steel bars be used in the manufacturing of reactor vessels?

- Yes, stainless steel bars can be used in the manufacturing of reactor vessels. Stainless steel is a type of alloy that contains iron, chromium, and other elements, which gives it excellent corrosion resistance properties. This makes stainless steel bars an ideal material for applications where the reactor vessel needs to withstand harsh conditions, such as high temperatures and corrosive environments. Stainless steel bars offer several advantages for reactor vessel manufacturing. Firstly, they have high strength and durability, allowing the vessel to withstand the internal pressure and external forces that it may encounter during operation. Secondly, stainless steel has excellent resistance to corrosion, which is crucial for reactor vessels that often come into contact with corrosive substances or high-temperature chemicals. This corrosion resistance helps to extend the lifespan of the reactor vessel and ensures its safe and reliable operation. In addition, stainless steel bars can be easily fabricated and welded, allowing for various shapes and sizes of reactor vessels to be produced. They also have good heat resistance properties, which is important for reactor vessels that experience high-temperature operations. Overall, stainless steel bars are a suitable choice for manufacturing reactor vessels due to their strength, corrosion resistance, and ability to withstand harsh operating conditions.

- Q:What are the different types of corrosion testing for stainless steel bars?

- There are several different types of corrosion testing methods that can be used to evaluate the corrosion resistance of stainless steel bars. Some of the most common types of corrosion testing include: 1. Salt Spray Test: This test involves exposing the stainless steel bars to a salt spray environment for a certain period of time. The bars are then inspected for signs of corrosion, such as rust or pitting. 2. Immersion Test: In this test, the stainless steel bars are immersed in a corrosive liquid, such as an acid or a salt solution, for a specific duration. The bars are then examined for any signs of corrosion. 3. Electrochemical Testing: This method involves using electrochemical techniques, such as polarization resistance or electrochemical impedance spectroscopy, to determine the corrosion rate and behavior of the stainless steel bars. It provides more detailed information about the corrosion process. 4. Crevice Corrosion Test: This test focuses on evaluating the susceptibility of stainless steel bars to crevice corrosion, which occurs in tight spaces or gaps. It involves creating a crevice between the bar and another material and exposing it to a corrosive environment. 5. Intergranular Corrosion Test: This test is performed to assess the susceptibility of stainless steel bars to intergranular corrosion, which can occur due to sensitization during welding or heat treatment. It typically involves subjecting the bars to a specific chemical solution or heat treatment and examining them for signs of intergranular corrosion. 6. Pitting Resistance Test: Pitting corrosion is a common form of corrosion in stainless steel. This test is designed to determine the resistance of stainless steel bars to pitting corrosion by subjecting them to a corrosive environment and evaluating the extent of pitting. These different types of corrosion testing methods help manufacturers and users of stainless steel bars to assess their corrosion resistance and choose the most suitable material for their specific applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

316TI Stainless Steel Round Bar price per kg for medical equipment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords