316L STAINLESS STEEL COILMADE in WUXI GOOD QUALITY AND CHEAP

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Description of the 316 stainless steel coil

316L stainless Steel adds Mo (2-3%), so it has excellent corrosion resistance and high temperature strength; SUS316L carbon content is lower than SUS316, therefore, the resistance to intergranular corrosion resistance is better than SUS316: high temperature creep strength is high. It can be used in harsh conditions.good strain hardening and non-magnetic.

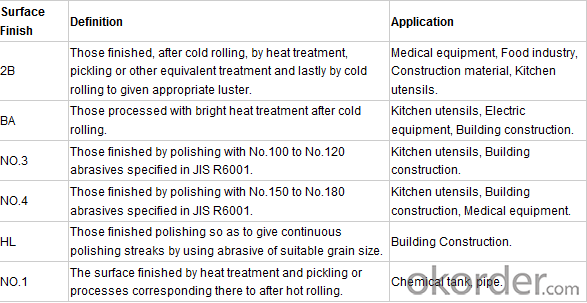

2,Applications of Stainless Steel Coils

3,related products show

4,Specification of the 316L stainless steel coil.

1. Our company has been dedicated to producing stainless steel seamless pipe since 2003, owning complete producing technology and abundant managing experience.

2. The raw material such as mother tube, round bar we use is from Chinese biggest and well-known steel mill: Walsin Steel and Yongxing Steel.

3. We have advanced NDT equipments for the tests such as Eddy Current test, Ultrasonic test, Hydraulic test and so on.

4. We have ISO 9001 and PED certificate, and the Third Party Inspection Certificates such as TUV, BV, Lloyd’s, SGS, etc, also can be provided according to customers’ requirements,

5. Wooden case package which is strong and suitable for sea transportation is our main method to pack the pipes. And the economical packing method such as packed in bundles is also welcomed by some customers.

6. The tolerance control we use is D4/T4 (+/-0.1mm) on both inside and outside Diameter and Wall Thickness, which is much higher than international standard ASTM, DIN.

7. The surface condition is one of our main advantages: in order to meet different requirements for surface condition, we have annealing and pickling surface, bright annealing surface, OD polished surface, OD & ID polished surface etc.

8. In order to keep the inside surface of pipe clean and make it free from deburring, our company develops the unique and special technology --- Sponge Washing with high pressure.

9. We have complete after-sale service to deal with the problems in time.

5,FAQ

1,How do you guarantee the quality of your product?

A: Every process will be checked by responsible QC which insures every product's quality.

2,How much is your daily output?

We can rate our daily output at about 200Ton-300Ton.

- Q:How do stainless steel strips handle exposure to caustic solutions?

- Stainless steel strips are highly resistant to caustic solutions due to their corrosion-resistant properties. They can withstand prolonged exposure to caustic solutions without undergoing any significant damage or corrosion, making them a reliable choice for applications in industries such as chemical processing, food processing, and pharmaceuticals.

- Q:What are the advantages of using stainless steel strips in the automotive industry?

- There are several advantages of using stainless steel strips in the automotive industry. Firstly, stainless steel is highly resistant to corrosion, which makes it ideal for use in vehicles that are exposed to harsh weather conditions and road salt. This helps prolong the lifespan of automotive components, reducing maintenance and replacement costs. Secondly, stainless steel strips offer excellent strength and durability, allowing them to withstand high levels of stress and impact. This makes them suitable for various applications in the automotive sector, such as structural supports, exhaust systems, and body panels, enhancing vehicle safety and performance. Furthermore, stainless steel strips have a sleek and attractive appearance, enhancing the aesthetics of automotive components. Their ability to retain a polished finish even after prolonged use adds to the overall appeal of vehicles. Lastly, stainless steel is a sustainable and eco-friendly material. It is fully recyclable, contributing to the reduction of waste and environmental impact in the automotive industry. Overall, the advantages of using stainless steel strips in the automotive industry include corrosion resistance, strength and durability, aesthetic appeal, and sustainability.

- Q:What are the factors affecting the electrical conductivity of 111 stainless steel strips?

- There are several factors that can affect the electrical conductivity of 111 stainless steel strips. 1. Alloy composition: The specific composition of the stainless steel alloy, including the type and amount of elements, can significantly impact its electrical conductivity. For instance, the presence of certain alloying elements like chromium, nickel, and manganese can enhance the conductivity, while other elements like carbon can decrease it. 2. Heat treatment: The heat treatment process used during the manufacturing of stainless steel strips can also influence their electrical conductivity. Heat treatment can modify the microstructure of the material, affecting the movement of electrons and thus altering its conductivity. 3. Grain size and orientation: The grain size and orientation of the stainless steel strips can have a notable impact on their electrical conductivity. Generally, smaller grain sizes and a more uniform grain orientation tend to result in higher conductivity as they allow for better electron flow. 4. Surface condition: The surface condition of the stainless steel strips can influence their electrical conductivity. Factors such as roughness, contamination, or oxidation can hinder the flow of electrons, leading to decreased conductivity. 5. Temperature: Temperature plays a significant role in the electrical conductivity of stainless steel strips. In general, the conductivity decreases with an increase in temperature due to the increased thermal vibrations of atoms, which can impede the movement of electrons. 6. Impurities and defects: The presence of impurities or defects within the stainless steel strips can affect their electrical conductivity. Impurities can introduce additional scattering centers for electrons, while defects like dislocations can hinder the flow of electrons, leading to reduced conductivity. 7. Mechanical deformation: Mechanical deformation, such as rolling or stretching, can alter the electrical conductivity of stainless steel strips. Deformation can modify the crystal structure and introduce dislocations, which can influence the movement of electrons and thus impact conductivity. It is important to note that the specific combination and interaction of these factors will ultimately determine the electrical conductivity of 111 stainless steel strips.

- Q:What is the tensile strength of stainless steel strips?

- The tensile strength of stainless steel strips can vary depending on their specific grade and thickness. However, stainless steel stands out for its superior tensile strength compared to other materials. On average, stainless steel strips exhibit a tensile strength range between 515 and 2,000 megapascals (MPa). It is worth noting that the manufacturing process and any additional treatments applied to the stainless steel can also impact its tensile strength. As a result, it is always recommended to consult the technical data sheet or seek guidance from a supplier for precise and comprehensive information regarding the tensile strength of a specific stainless steel strip.

- Q:Are stainless steel strips corrosion-resistant?

- Yes, stainless steel strips are corrosion-resistant due to the presence of chromium in their composition, which forms a protective layer on the surface, preventing rust and corrosion.

- Q:Can stainless steel strips be used in medical applications?

- Yes, stainless steel strips can be used in medical applications. Stainless steel is a commonly used material in the medical field due to its excellent corrosion resistance, high strength, and ease of sterilization. Stainless steel strips are often used for various medical devices and equipment, such as surgical tools, implants, dental instruments, and medical tubing. The material's resistance to corrosion and ability to withstand high temperatures make it ideal for applications where cleanliness and sterility are crucial. Additionally, stainless steel is biocompatible, meaning it does not cause any adverse reactions when in contact with living tissue. Overall, stainless steel strips are a suitable choice for medical applications due to their durability, reliability, and compatibility with the human body.

- Q:Can stainless steel strips be used for heat exchanger plates?

- Yes, stainless steel strips can be used for heat exchanger plates. Stainless steel is a popular choice for heat exchangers due to its excellent corrosion resistance, high strength, and thermal conductivity. The strips can be formed into the required shape and size, making them suitable for use as heat exchanger plates.

- Q:Can stainless steel strips be used in the production of HVAC grilles?

- Yes, stainless steel strips can be used in the production of HVAC grilles. Stainless steel is a popular material choice for HVAC grilles due to its durability, corrosion resistance, and aesthetic appeal. The use of stainless steel strips in the production of HVAC grilles ensures that the grilles will be able to withstand the harsh conditions of heating, ventilation, and air conditioning systems without rusting or deteriorating over time. Additionally, stainless steel strips offer a sleek and modern appearance, making them an ideal choice for architectural and design purposes. Overall, stainless steel strips are a suitable and reliable option for manufacturing HVAC grilles.

- Q:What is the embrittlement temperature of stainless steel strips?

- The embrittlement temperature of stainless steel strips can vary depending on the specific grade and composition of the stainless steel. Generally, stainless steel is known for its excellent toughness and resistance to brittleness, even at low temperatures. However, certain conditions may cause embrittlement in stainless steel. One factor that can contribute to embrittlement is the presence of hydrogen. In certain environments, such as high-pressure hydrogen gas or hydrogen sulfide-containing environments, stainless steel can undergo hydrogen embrittlement. The embrittlement temperature in these cases can be relatively low, typically in the range of 200-500°C (392-932°F). Another factor that can affect the embrittlement temperature is the carbon content of the stainless steel. Higher carbon content can lead to sensitization, which can make the steel susceptible to intergranular corrosion and subsequent embrittlement. The embrittlement temperature due to sensitization can vary depending on the specific grade of stainless steel, but it is generally in the range of 450-850°C (842-1562°F). It is important to note that these embrittlement temperatures are approximate ranges and can vary based on the specific grade, composition, and processing history of the stainless steel. Therefore, it is always recommended to consult the specific technical data and guidelines provided by the stainless steel manufacturer or industry standards to determine the embrittlement temperature for a particular stainless steel strip.

- Q:Can stainless steel strips be bent or shaped?

- Yes, stainless steel strips can be bent or shaped. Stainless steel is a highly malleable material, meaning it can be easily manipulated into various forms and shapes. With the proper tools and techniques, stainless steel strips can be bent, curved, or formed into a desired shape. The bending or shaping process typically involves using specialized machines such as press brakes, rollers, or mandrels, which apply force to the stainless steel strip to achieve the desired shape. Additionally, the thickness and tempering of the stainless steel strip can also affect its bendability and shapeability. Overall, stainless steel strips offer a great amount of flexibility and can be easily manipulated to fit various applications and designs.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

316L STAINLESS STEEL COILMADE in WUXI GOOD QUALITY AND CHEAP

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords