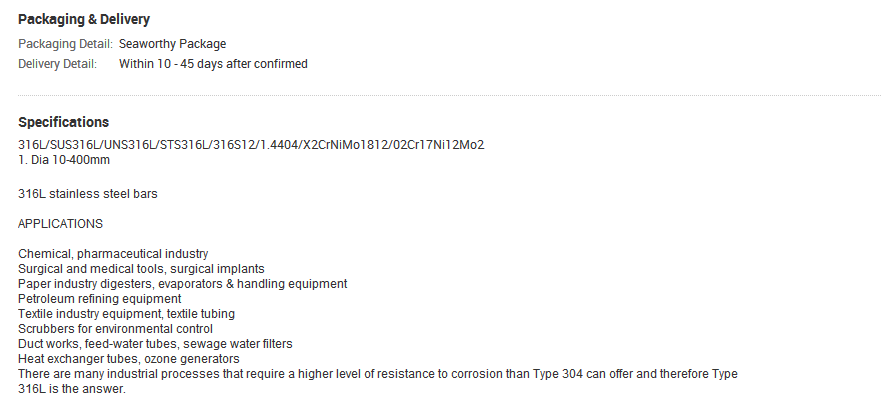

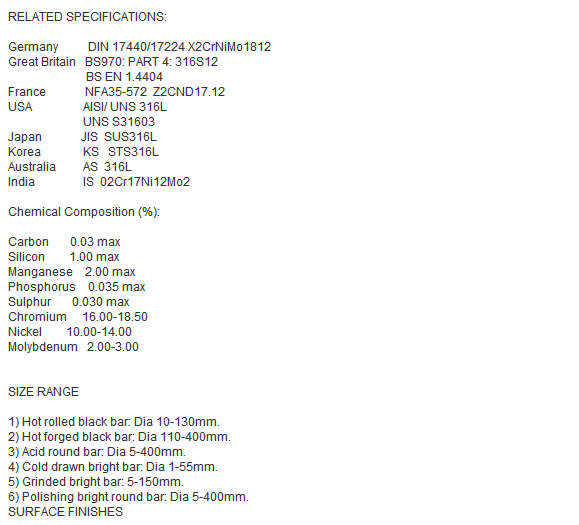

316L Black/Acid/Bright/Grinded stainless steel bars

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q:What is the difference between 2205 and 2507 stainless steel pipes?

- The main difference between 2205 and 2507 stainless steel pipes lies in their chemical composition and corrosion resistance properties. 2205 stainless steel is a duplex stainless steel that contains a balanced proportion of austenite and ferrite phases. It consists of about 22% chromium, 5% nickel, 3% molybdenum, and small amounts of nitrogen and other elements. This composition provides 2205 stainless steel with good strength, excellent corrosion resistance, and high resistance to stress corrosion cracking. On the other hand, 2507 stainless steel is a super duplex stainless steel that contains higher levels of chromium, nickel, molybdenum, and nitrogen compared to 2205. It typically comprises approximately 25% chromium, 7% nickel, 4% molybdenum, and 0.25% nitrogen, along with other alloying elements. These additions enhance the corrosion resistance, strength, and overall performance of 2507 stainless steel pipes, particularly in highly corrosive environments such as seawater, chemicals, and acidic solutions. In terms of corrosion resistance, 2507 stainless steel pipes offer superior resistance to pitting, crevice corrosion, and general corrosion compared to 2205 stainless steel. This makes 2507 stainless steel pipes highly suitable for applications where extreme corrosion resistance is required, such as offshore oil and gas platforms, chemical processing plants, and desalination plants. Overall, while both 2205 and 2507 stainless steel pipes are duplex stainless steels, the higher alloy content and enhanced corrosion resistance of 2507 stainless steel pipes make them more suitable for severe and corrosive environments. However, 2205 stainless steel pipes still offer excellent performance and can be a cost-effective alternative in less demanding applications.

- Q:How do you calculate the weight of stainless steel pipes?

- In order to determine the weight of stainless steel pipes, several factors should be taken into account. Firstly, one needs to establish the pipe's outer diameter (OD) and thickness (T). Once these measurements have been obtained, the weight per foot (or meter) of the stainless steel pipe can be calculated using the following formula: Weight per foot (or meter) = (OD - T) * T * 0.0246615 It should be noted that this formula assumes the stainless steel pipe is of a circular shape. By multiplying the weight per foot by the length of the pipe in feet (or meters), the total weight can be determined. It is important to acknowledge that the density of stainless steel may vary depending on the specific grade and composition. Therefore, the weight calculated using this formula will provide an approximate value. For precise weight calculations, it is advisable to consult a reference table or contact the manufacturer for more accurate information.

- Q:Can stainless steel pipes be used for brewery applications?

- Yes, stainless steel pipes can be used for brewery applications. Stainless steel is highly resistant to corrosion and can withstand the harsh conditions of a brewery environment, such as exposure to moisture and chemicals. It is also easy to clean and maintain, making it a suitable choice for transporting liquids in a brewery setting.

- Q:Are stainless steel pipelines buried in need of corrosion protection?

- The factors of the material itself: stainless steel pipe structure exists because of the equipment, or the existence of cracks of metal or non-metal deposits on the surface, in the sediment and the stainless steel tube surface in the formation of cracks, corrosion, will give priority to produce punctate and ulcer like damage in the crevice, which is crevice corrosion.

- Q:What are the limitations of using stainless steel pipes?

- Some limitations of using stainless steel pipes include their higher cost compared to other materials, their susceptibility to corrosion in certain environments, and their lower thermal conductivity compared to materials like copper. Additionally, stainless steel pipes may be more difficult to cut and weld, and their strength and durability may vary depending on the specific grade of stainless steel used.

- Q:Can stainless steel pipes be mirror polished?

- Yes, stainless steel pipes can be mirror polished.

- Q:Can stainless steel pipes be coated with epoxy?

- Yes, stainless steel pipes can be coated with epoxy. Epoxy coating provides excellent corrosion resistance and can be applied to stainless steel pipes to enhance their durability and protect against various environmental factors.

- Q:Are stainless steel pipes suitable for chemical storage tanks?

- Yes, stainless steel pipes are typically suitable for chemical storage tanks. Stainless steel is highly resistant to corrosion and can withstand the harsh chemicals stored in tanks, making it a preferred material for chemical storage applications.

- Q:Can stainless steel pipes be used for solar power plants?

- Yes, stainless steel pipes can be used for solar power plants. Stainless steel is highly resistant to corrosion and can withstand the harsh environmental conditions typically found in solar power plants. It offers excellent durability and longevity, making it a suitable choice for transporting various fluids and gases in the solar power plant infrastructure.

- Q:How do you prevent discoloration in stainless steel pipes?

- To avoid discoloration in stainless steel pipes, there are several precautions that can be implemented: 1. Implement proper cleaning techniques: It is recommended to regularly cleanse the stainless steel pipes using mild soap or detergent and warm water. The use of harsh chemicals or abrasive cleaners that could potentially harm the surface and result in discoloration should be avoided. 2. Thoroughly rinse the pipes: After cleaning, ensure that the pipes are rinsed thoroughly with clean water to eliminate any residue or cleaning agents that might cause discoloration. 3. Steer clear of corrosive substances: It is advised to keep stainless steel pipes away from direct contact with corrosive substances such as strong acids, alkaline solutions, or chlorides. These substances have the potential to initiate chemical reactions, resulting in discoloration. 4. Apply protective coatings: The application of protective coatings, such as clear lacquer or specialized stainless steel protective sprays, can effectively prevent discoloration by creating a barrier between the metal surface and the environment. 5. Control temperature levels: Excessive heat has the capacity to cause discoloration in stainless steel pipes. Hence, it is crucial to regulate the temperature of the surrounding environment or the fluid passing through the pipes to prevent overheating. 6. Regularly maintain the pipes: Consistent inspections and maintenance should be conducted to promptly identify any indications of discoloration or damage and address them accordingly. This includes checking for leaks, corrosion, or any other factors that may contribute to discoloration. By adhering to these preventive measures, the risk of discoloration in stainless steel pipes can be significantly reduced, enabling them to maintain their aesthetic appeal and functionality for an extended duration.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

316L Black/Acid/Bright/Grinded stainless steel bars

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords