316 Stainless Steel Sheet Hot Rolled NO.1

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2400 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

CNBM International Corporation

CNBM International Corporation

Stainless steel

CNBM began to domestic trade since 70S,now we also sell stainless steel aborad.

We are the agent of TISCO,BAOSTEEL,LISCO,JISCO,ZPSS.

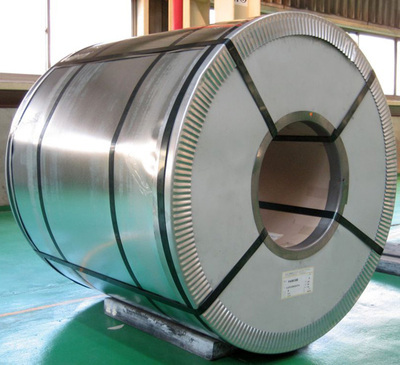

Our main products are stainless steel inox sheet/plate,coil/roll,strip,bar,angle,pipe and tube.

Grade-- 201,202,304,304L,316,316L,310S,309S,301,321,904L,410,420,430,409.

Surface--2B,BA,No.4/HL/Hairline/brushed/satin,8K/No.8/mirror,SB,gold,etch,No.1,polish.

Thickness--0.2-6mm for cold rolled; 3-150mm for hot rolled.

Width:10mm-2000mm for coil.

Standard size --1000×2000mm,1219×2438mm=4ft×8ft=1220×2440mm,

1250×2500mm,1500×3000/6000mm,1524×6096mm.For sheets/plates.

Certificate--ISO,BV,SGS,TUV,IQI or other third inspections.

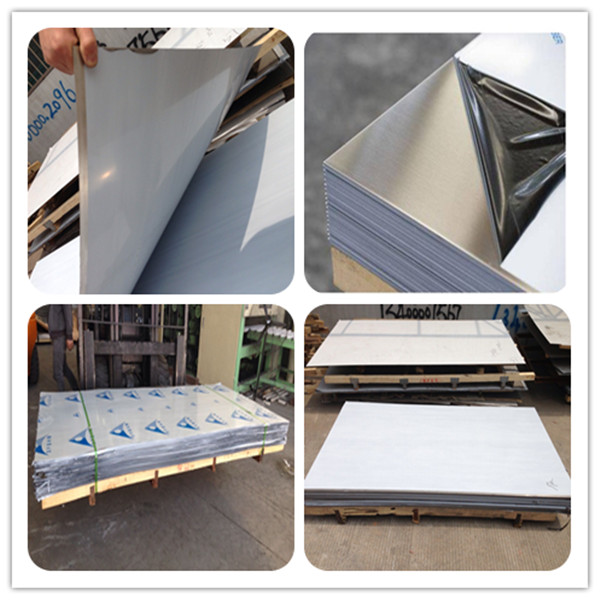

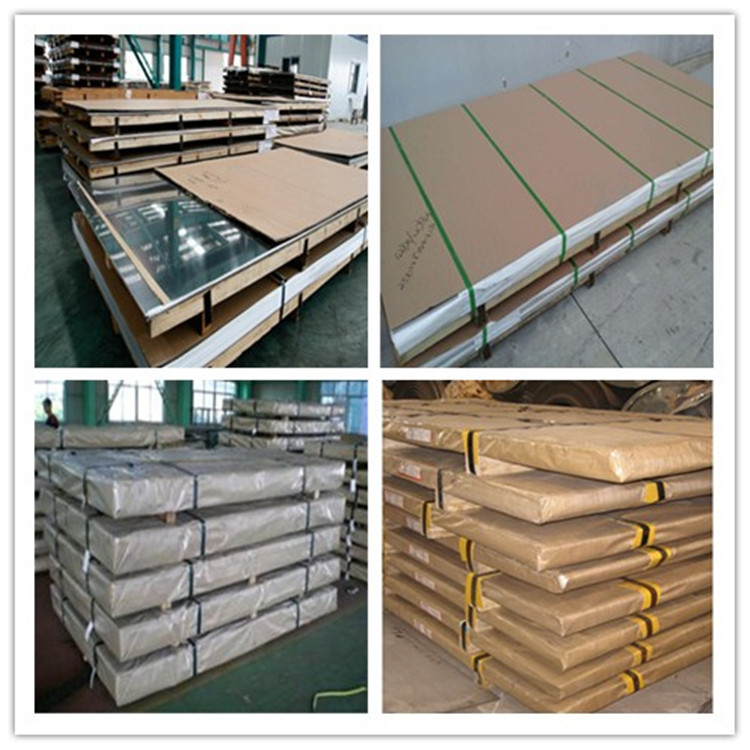

Package--wooden pallets with fimugated,iron pallets,water proof papers,

interleaved paper,pvc film,20'GP or 40'GP container.

Product Description

Description of 316 stainless steel hot rolled no.1

1 | Product Name | 316 stainless steel hot rolled no.1 |

2 | Material | ASTM 301, ASTM304,ASTM304L, ASTM 316, ASTM316Ti,ASTM309S, ASTM310S, ASTM321, ASTM347H,ASTM A317,ASTMA317L, ASTM409,ASTM409L,ASTM410,ASTM420,ASTM430 ASTM 201,ASTM202, |

3 | Technique | Cold Rolled Stainless Steel plate Cold Drawn Stainless Steel plate Hot Rolled Stainless Steel plate |

4 | Standard | ASTM,AISI,ASME,JIS,SUS,DIN,EN,GB,BS |

5 | Thickness | 0.2-6.0mm for cold rolled 3.0-300mm for hot rolled |

Width | 600-3000mm | |

Length | Any, as your requirement | |

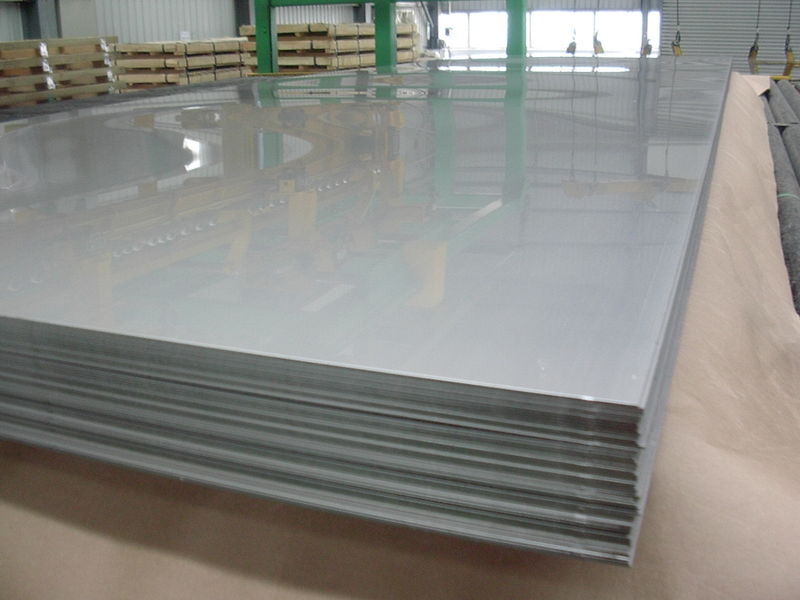

6 | Surface Treatment | No.1, NO.4 ,2B, BA, Hair Line,8K,Brush,Embossed and Mirror Finish or as your demand |

7 | Packing | Standard export packing-For stainless steel sheet 1.surface polish 2. bundle package 3. wooden case , wooden pallet package 4:container or bulk 5. special according to customer request |

8 | Delivery | Normally according to the order quantity or upon negotiation |

9 | Price Item | FOB,CFR,CIF Or as negotiated |

10

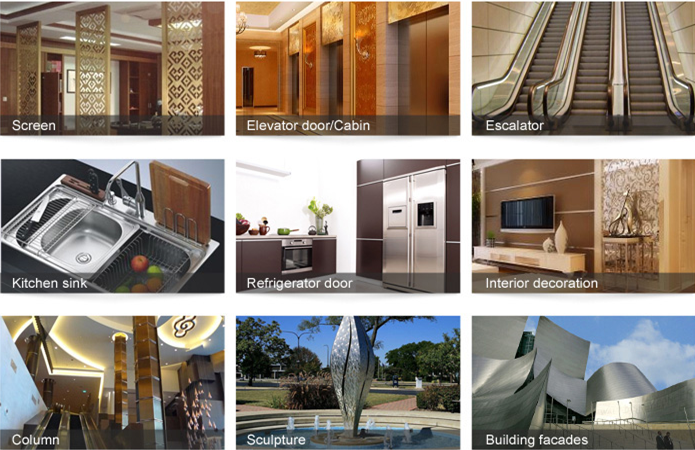

| Application | Stainless Steel plate are widely used in below fields: 1: Construction feild,shipping building industry 2: Petroleum and Chemical Industries 3: Food and Machenical Industries 4: Boiler Heat Exchange 5: Machinery and Hardware Industries |

Production of 316 stainless steel hot rolled no.1

Mechanical property of 316 stainless steel hot rolled no.1

| Tensile Strength | σb (MPa)≥520 |

| Offset Yield Strength | σ0.2 (MPa)≥205 |

| Elongation | δ5 (%)≥40 |

| Hardness | ≤187HB;≤90HRB;≤200HV |

| Density(20℃,g/cm3) | 7.98 |

Chemical composition of 316 stainless steel hot rolled no.1

| 316 | C | Si | Mn | P | S | Ni | Cr | Mo |

| % | ≤0.08 | ≤1 | ≤2 | ≤0.035 | ≤0.030 | 10.0~14.0 | 16.0~18.5 | 2.00-3.00 |

Maintenance of 316 stainless steel hot rolled no.1

Regular cleaning and maintenance

Pay attention to prevent the occurrence of the phenomenon of surface scratches

Use soap, weak detergent or warm water to remove surface dust, dirt

In addition to the surface of the binder with alcohol or an organic solvent (ether, benzene)

Use neutral detergent or ammonia solution in addition to surface oil

With 10% nitric acid or abrasive detergent in addition to the surface of the embroider caused by the dirt.

Packaging & Shipping

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

After-sale service:

CNBM provides the services and support you need for every step of our cooperation.

We’re the business partners you can trust; you can relax and get on with doing business.

For any problem, please kindly contact us at any your convenient time,

we’ll reply you in our first priority within 24 hours

Application

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories

- Q:Can stainless steel sheets be used for outdoor furniture or fixtures?

- Yes, stainless steel sheets can be used for outdoor furniture or fixtures. Stainless steel is highly resistant to corrosion, making it a suitable material for outdoor applications. It is durable, weather-resistant, and can withstand harsh environmental conditions. Additionally, stainless steel has an attractive appearance and can be easily cleaned and maintained, making it an ideal choice for outdoor furniture or fixtures.

- Q:Is there a big price difference between the SUS304 stainless steel plate and the drawing plate?

- The ordinary 304 stainless steel plate and the processed 304 drawing stainless steel plate, the price difference is not very big. You can consult the specific price.

- Q:Are stainless steel sheets suitable for industrial applications?

- Yes, stainless steel sheets are highly suitable for industrial applications due to their exceptional strength, durability, corrosion resistance, and heat resistance properties. They can withstand harsh conditions, maintain their integrity, and provide long-lasting performance, making them ideal for various industrial sectors such as automotive, aerospace, construction, and manufacturing.

- Q:Stainless steel sheet welding method, thickness of 0.5mm

- Common welding method: pulse DC TIG welding.

- Q:Stainless steel plate surface treatment: ink, wire drawing, polishing what role?

- Oil mill, also known as "snow silk", "broken wire", is a kind of anti fingerprint drawing, used in the elevator car. It is to use the 4# wire drawing machine grinding, with grease to reduce the temperature generated by the board, so that the board surface to maintain smooth, non deformation

- Q:How do you remove rust from stainless steel sheets?

- To remove rust from stainless steel sheets, there are a few effective methods you can try. Here are a few options: 1. Vinegar: Vinegar is an excellent natural cleaner that can remove rust from stainless steel. Soak a cloth or sponge in white vinegar and rub it onto the rusted areas. Let it sit for a few minutes, then scrub the rust away with a soft-bristle brush. Rinse the sheet with water and dry it thoroughly. 2. Lemon juice and baking soda: Create a paste by mixing lemon juice and baking soda together. Apply the paste to the rusted areas and let it sit for about 10-15 minutes. Scrub the rust away with a soft cloth or sponge, rinse the sheet, and dry it completely. 3. Commercial rust remover: If the rust is stubborn or extensive, you can use a commercial rust remover specifically designed for stainless steel. Follow the instructions on the product and wear protective gloves as some rust removers can be harsh. After applying the rust remover, rinse the sheet thoroughly and dry it well. 4. Sanding or wire brushing: For more severe rust, you can use sandpaper or a wire brush to remove the rust manually. Start with a coarser grit sandpaper or brush and gradually move to a finer grit until the rust is completely removed. Be sure to sand or brush in the direction of the grain to avoid scratching the stainless steel surface. Afterward, clean the sheet with a mild detergent, rinse, and dry thoroughly. Remember to always test any cleaning method or product on a small, inconspicuous area of the stainless steel sheet first to ensure it doesn't cause any damage. Additionally, regular maintenance and proper storage can help prevent future rust formation on stainless steel sheets.

- Q:How do I prevent corrosion under insulation on stainless steel sheets?

- To prevent corrosion under insulation on stainless steel sheets, there are several steps you can take: 1. Proper insulation selection: Choose insulation materials that are compatible with stainless steel and have a low water absorption rate. Avoid using materials that can cause galvanic corrosion when in contact with stainless steel. 2. Adequate insulation thickness: Ensure that the insulation thickness is sufficient to prevent moisture condensation on the stainless steel surface. Condensation can trap moisture and accelerate corrosion. Consult with an insulation specialist to determine the appropriate thickness for your specific application. 3. Vapor barriers: Install vapor barriers between the insulation and the stainless steel sheets. Vapor barriers act as a moisture barrier, preventing the ingress of water or moisture that can lead to corrosion. These barriers can be made of materials such as foil or plastic films. 4. Proper installation: Ensure that the insulation is properly installed, with no gaps or areas where moisture can accumulate. Pay close attention to joints, seams, and connections, making sure they are tightly sealed to prevent water penetration. 5. Regular inspection and maintenance: Regularly inspect the insulation system to identify any signs of damage, such as leaks or deterioration. Promptly repair any damaged insulation or vapor barriers to prevent moisture from reaching the stainless steel surface. 6. Ventilation: Provide adequate ventilation to prevent moisture buildup in enclosed spaces. Good airflow can help reduce the chances of condensation and subsequent corrosion. 7. Cathodic protection: Consider using cathodic protection methods, such as sacrificial anodes or impressed current systems, to protect stainless steel sheets from corrosion. These methods create an electrical current that counteracts the corrosion process, extending the lifespan of the stainless steel. Remember, it is essential to consult with corrosion specialists or insulation experts to ensure the best practices are implemented for your specific application and environment.

- Q:What is the strength of stainless steel sheets?

- The strength of stainless steel sheets can be attributed to several factors. Firstly, stainless steel is an alloy of iron and chromium, which provides it with excellent corrosion resistance. This resistance to corrosion makes stainless steel sheets ideal for various applications, including in environments where they may be exposed to moisture, chemicals, or extreme temperatures. In addition to corrosion resistance, stainless steel sheets also possess high tensile strength. Tensile strength refers to the maximum amount of tensile stress a material can withstand before failure. Stainless steel sheets have a high tensile strength, allowing them to withstand heavy loads and resist deformation or breaking under pressure. Furthermore, stainless steel sheets exhibit excellent durability and hardness. This means that they can withstand wear and tear, making them suitable for applications that require long-lasting and robust materials. Stainless steel sheets are also known for their high resistance to heat, which enables them to maintain their structural integrity even at elevated temperatures. Another strength of stainless steel sheets is their versatility. They can be fabricated into various shapes and sizes, making them suitable for a wide range of applications. Additionally, stainless steel sheets can be easily formed, welded, and machined, allowing for customization to meet specific requirements. Overall, the strength of stainless steel sheets lies in their corrosion resistance, high tensile strength, durability, hardness, heat resistance, and versatility. These properties make stainless steel sheets a reliable and trusted material in numerous industries, including construction, automotive, aerospace, food processing, and many others.

- Q:Can stainless steel sheets be painted?

- Yes, stainless steel sheets can be painted. However, it is important to properly prepare the surface to ensure good adhesion. This typically involves cleaning, sanding, and applying a primer before painting.

- Q:Are stainless steel sheets resistant to chlorine?

- Stainless steel sheets possess a general resistance to chlorine, as they are renowned for their corrosion-resistant properties. They are capable of enduring exposure to chlorine without experiencing substantial degradation. Hence, stainless steel sheets prove to be an appropriate option for implementing in environments containing chlorine, such as swimming pools, water treatment plants, and chemical processing facilities. Nevertheless, it is crucial to acknowledge that extended exposure to high concentrations of chlorine or specific chemicals can still induce corrosion or discoloration on the surfaces of stainless steel. To maintain the longevity and aesthetic appeal of stainless steel sheets in chlorinated settings, regular maintenance and adherence to proper cleaning procedures are imperative.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

316 Stainless Steel Sheet Hot Rolled NO.1

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2400 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords