316 Hard Stainless Steel Sheet Mirror Finish Hot Rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Mirror Finish Hot Rolled 316 Hard Stainless Steel Sheet

Name | Mirror Finish Hot Rolled 316 Hard Stainless Steel Sheet |

Grade | 304/316L/321/310S/2205 |

Thickness | 0.3mm-20.00mm |

Width | 1000mm-2000mm |

Length | 6m or as customers' request |

Tolerance | Thickness: ±0.02mm Length: ± 5mm |

Brand | BAOSTEEL,TISCO,ZPSS |

Standard | ISO,ASTM,SUS,GB etc |

Surface | 2B,BA,6K,8K,12K,No1,Polished, |

Place of origin | Wuxi China (mainland) |

Application | Decoration Industry Kitchenwave Building Elevator Upholstery

|

Packing | Standard export seaworthy package or as customer |

Payment terms | 1.30%T/T in advance ,the balance against the B/L copy 2.30%T/T in advance,the balance be paid by L/C at sight |

Surface--stainless steel sheet

Surface | Definition | Application | Photo |

| NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |  |

| 2B | Those finished, after cold rolling, by heat treatment,pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry,Construction material, Kitchen utensils. |  |

| BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils. Electric equipment,Building construction. |  |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction,Medical equipment. |  |

| HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size | Building Construction. |  |

Chemical Composition(%) of Stainless Steel Sheet

No. | Grade | Chemical Composition % | ||||||||||

C | Cr | Ni | Mn | P | S | Mo | Si | Cu | N | Other | ||

201 | 1Cr17Mn6Ni5N | ≤0.15 | 16.00-18.00 | 3.50-5.50 | 5.50-7.50 | ≤0.060 | ≤0.030 | - | ≤1.00 | - | ≤0.25 | - |

202 | 1Cr18Mn8Ni5N | ≤0.15 | 17.00-19.00 | 4.00-6.00 | 7.50-10.00 | ≤0.060 | ≤0.030 | ≤1.00 | - | ≤0.25 | - | |

301 | 1Cr17Ni7 | ≤0.15 | 16.00-18.00 | 6.00-8.00 | ≤2.00 | ≤0.065 | ≤0.030 | - | ≤1.00 | - | - | - |

304 | 0Cr18Ni9 | ≤0.07 | 17.00-19.00 | 8.00-10.00 | ≤2.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | - | - | - |

304L | 00Cr19Ni10 | ≤0.030 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | - | - | - |

310S | 0Cr25Ni20 | ≤0.08 | 24.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | - | - | - |

316 | 0Cr17Ni12Mo2 | ≤0.08 | 16.00-18.50 | 10.00-14.00 | ≤2.00 | ≤0.035 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | - | - |

0Cr18Ni12Mo2Ti | ≤0.08 | 16.00-19.00 | 11.00-14.00 | ≤2.00 | ≤0.035 | ≤0.030 | 1.80-2.50 | ≤1.00 | - | - | Ti5*C%-0.70 | |

316L | 00Cr17Ni14Mo2 | ≤0.030 | 16.00-18.00 | 12.00-15.00 | ≤2.00 | ≤0.035 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | - | - |

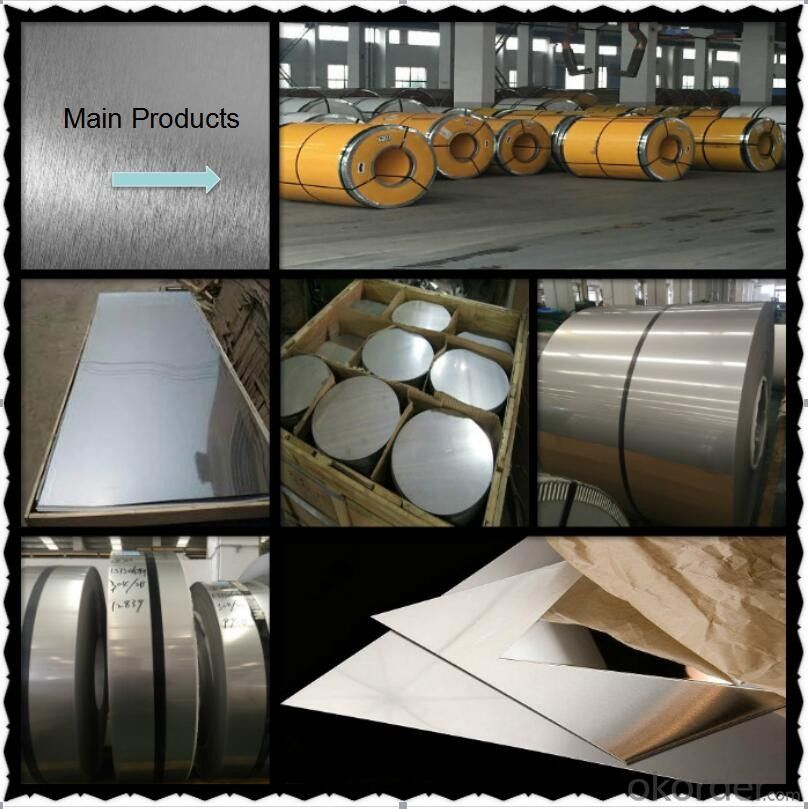

Production Show

Applications

Be extensively applied to architectural decoration, such as elevator decoration, luxurious doors, outdoor projects, wall decoration, advertisement nameplates, sanitary ware, ceiling, corridor, hotel hall, shop facade.Kitchenware, food industry, electronic industry, medical equipment, etc.

Chemical Compositon and Physical Property:

| Type | Chemical Composition (%) | |||||

| 410 | C | SI | Mn | S | P | Cr |

| 0.03 | 0.32 | 0.25 | 0.001 | 0.019 | 12.21 | |

- Q:What are the bending limits of stainless steel sheets?

- The bending limits of stainless steel sheets depend on several factors such as the grade of stainless steel, thickness of the sheet, and the specific type of bending process being used. Stainless steel sheets are known for their excellent strength and durability, which allows them to be bent to a certain extent without breaking or cracking. In general, stainless steel sheets can be bent to a radius that is at least twice the thickness of the sheet. For example, if the sheet is 1mm thick, it can typically be bent to a minimum radius of 2mm. However, it is important to note that this is just a general guideline and the actual bending limits may vary depending on the specific grade of stainless steel. Certain grades of stainless steel, such as 304 and 316, have higher yield strengths and are more resistant to deformation, making them suitable for more severe bending applications. Thicker sheets also have higher bending limits compared to thinner ones, as they have more material to withstand the bending forces. It is also worth mentioning that the type of bending process used can affect the bending limits of stainless steel sheets. Processes like press brake bending and roll bending are commonly used for bending stainless steel sheets. These processes utilize different techniques and equipment, which can result in varying bending limits. To determine the exact bending limits for a specific grade and thickness of stainless steel sheet, it is best to consult the manufacturer's specifications or seek guidance from a professional metal fabricator. They can provide accurate information and guidance on the bending capabilities of stainless steel sheets for your specific application.

- Q:What is the magnetic permeability of stainless steel sheets?

- The magnetic permeability of stainless steel sheets is typically very low, making them non-magnetic or only weakly magnetic.

- Q:Are stainless steel sheets fire resistant?

- The fire resistance properties of stainless steel sheets are exceptional. With their high melting point and low thermal conductivity, stainless steel can endure prolonged exposure to high temperatures without experiencing significant structural alterations or losing strength. As a result, stainless steel sheets possess remarkable resistance to fire and heat harm. Furthermore, stainless steel does not emit toxic fumes when exposed to fire, further enhancing its safety in environments prone to fires. Consequently, stainless steel sheets are frequently employed in situations where fire resistance is of utmost importance, such as the construction of fire doors, fire escapes, and fire-resistant enclosures.

- Q:Can stainless steel sheets be used for water tanks?

- Yes, stainless steel sheets can be used for water tanks. Stainless steel is highly resistant to corrosion and can withstand the demands of storing water. It is a common material choice for water tanks due to its durability, hygiene, and longevity.

- Q:Can stainless steel sheets be used for water pipelines?

- Yes, stainless steel sheets can be used for water pipelines. Stainless steel is highly resistant to corrosion and has excellent strength, making it a suitable material for water pipelines that require durability and longevity. Additionally, stainless steel's smooth surface helps to maintain water flow efficiency and prevent contamination.

- Q:Can stainless steel sheets be cut or shaped?

- Yes, stainless steel sheets can be cut or shaped to meet specific requirements. Stainless steel is a versatile material that can be easily manipulated using different cutting and shaping techniques. Cutting stainless steel sheets can be done using methods such as shearing, laser cutting, or waterjet cutting. Shaping stainless steel sheets can be achieved through processes like bending, rolling, or stamping. These techniques allow for the creation of various forms and designs, making stainless steel sheets a popular choice in industries such as construction, automotive, and manufacturing.

- Q:What is the abrasion resistance of stainless steel sheets?

- The abrasion resistance of stainless steel sheets is generally high due to their strong and durable nature. They are able to withstand mechanical wear and tear, making them suitable for applications where frequent contact or friction occurs.

- Q:Are stainless steel sheets resistant to nitric acid?

- Stainless steel sheets are typically known for their resistance to nitric acid. Nitric acid, an extremely powerful oxidizing agent, has the ability to corrode and dissolve numerous metals. However, stainless steel contains a significant amount of chromium, which creates a protective oxide layer on the material's surface. This oxide layer acts as a barrier, effectively preventing direct contact between the nitric acid and stainless steel, thereby providing corrosion resistance. It is crucial to acknowledge that the level of resistance may differ depending on various factors such as the grade and composition of the stainless steel, as well as the nitric acid's concentration and temperature.

- Q:Are stainless steel sheets suitable for architectural applications?

- Architectural applications greatly benefit from the suitability of stainless steel sheets. This material, known for its versatility and durability, offers numerous advantages for architectural projects. Its exceptional corrosion resistance makes it an ideal choice for outdoor applications exposed to harsh weather conditions. Additionally, stainless steel is easily cleaned and maintained, ensuring a visually appealing and long-lasting finish. Not only does stainless steel provide functional benefits, but it also enhances the architectural design with its aesthetic appeal. Its sleek and modern appearance can complement a variety of styles, ranging from contemporary to industrial. Architects have ample design flexibility as stainless steel can be fabricated into different shapes and sizes. Moreover, stainless steel sheets find extensive use in various architectural applications. They are commonly employed in cladding, roofing, and façade systems, adding a distinct and eye-catching element to buildings. Furthermore, stainless steel can be incorporated into interior design elements such as wall panels, handrails, and decorative finishes, creating a sophisticated and luxurious atmosphere. Overall, stainless steel's exceptional properties, combined with its aesthetic appeal and versatility, make it an excellent choice for architectural applications. Its durability, corrosion resistance, and ease of maintenance make stainless steel sheets a reliable and long-lasting option for architects and designers.

- Q:Are stainless steel sheets resistant to acetic acid?

- Yes, stainless steel sheets are generally resistant to acetic acid. Acetic acid is a weak acid and does not cause significant corrosion or damage to stainless steel. However, prolonged exposure to highly concentrated or boiling acetic acid may cause some corrosion or staining on the surface of the stainless steel. It is important to note that the resistance of stainless steel to acetic acid can vary depending on the specific grade and composition of the stainless steel.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

316 Hard Stainless Steel Sheet Mirror Finish Hot Rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords