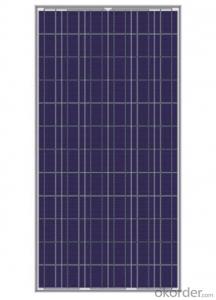

315W Polycrystalline silicon solar panels

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200000 watt

- Supply Capability:

- 20000000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Solar cell module production process

Line called packaging line components, packaging is the production of solar cells a key step in the packaging process without a good, multi-well battery is also not a good component of production boards. Battery package not only the battery life is guaranteed, but also to enhance the combat strength of the battery. Product quality and high service life is to win can be the key to customer satisfaction, so the quality of components of the package board is very important.

Process is as follows:

1, the battery test

2, positive Welding - Inspection –

3, on the back of cascading - Inspection –

4, laying (glass cleaning, material cutting, glass pre-processing, laying) –

5, laminating –

6, to flash ( to the side, cleaning) –

7, fitted border (glue, loading angle keys, punching, install box, scrub I glue) –

8, the welding junction box –

9, high-pressure test –

10, component testing -- -

11 appearance inspection, packaging and storage;

Data sheet

Maximum power | 315W |

Cell type(mm) | Polycrystalline solar cell 156*156 |

Number of cell(pcs) | 72(6*12) |

Manufacture site | China |

Open-circuit voltage(voc) | 45.1V |

Maximum power voltage(vmp) | 37.3V |

Short-circuit current(isc) | 8.88A |

Optimum operating current(imp) | 8.45A |

Power tolerance | 0~+5W |

Module efficiency | 16.2% |

Dimensions(mm) | 1956*992*40 |

Weight | 27 kg |

Backsheet | Silver |

Frame Colar | White |

Frame | Anodized Aluminum Alloy |

Standard Test Conditions of Polycrystalline Silicon Solar Panel

The opto-electrical specifications shown below are stabilized values being measured at Standard Test Conditions of multicrystalline silicon Solar Panel, Irradiance: 1000W/m2, Spectrum: AM1.5 at 25°C, The info below is subject to manufacturing tolerances. Where appropriate minutes of measurement are available and are used for the dimensioning of the installation.

Advantages of Polycrystalline Silicon Solar Panel

A&M Solar performance guarantees for 25 years

12 years guarantee for workmanship for multicrystalline silicon Solar Panel

Timeliness of delivery

Quality Products certified (TÜV, UL, CE, VDE, ISO)

- Q:How do solar panels affect the property's energy management strategy?

- Solar panels can have a significant impact on a property's energy management strategy. By harnessing the sun's energy, solar panels generate clean and renewable electricity, reducing the property's dependence on traditional power sources. This can lead to lower energy costs, increased energy independence, and a reduced carbon footprint. Solar panels also provide a stable and reliable source of energy, allowing for better energy planning and management. Additionally, excess energy generated by solar panels can be stored or sold back to the grid, providing additional financial benefits. Overall, solar panels play a crucial role in shaping and optimizing a property's energy management strategy.

- Q:Can solar panels be used to power a camping trip?

- Yes, solar panels can be used to power a camping trip. They are a sustainable and portable energy source that can be used to charge electronic devices, power lights, and even run small appliances while camping.

- Q:i need technical and non technical details to generate MW power by solar panels

- I like Rouse's answer, which points to the factors to consider. If you are in India, adjust the inputs to match your local situation. For example, the peak equivalent sun-hours per day might be twice his figure, leading to half the cost. You might find panels that have a 25-year life, reducing the cost per kWh by another 20%. Land and/or labor may be cheaper, also reducing the cost.

- Q:Can solar panels be damaged by birds or other animals?

- Yes, solar panels can be damaged by birds or other animals. Birds may build nests under the panels or peck at the wiring, leading to potential system malfunctions. Similarly, other animals like squirrels or rodents may chew on the wires or cause physical damage to the panels. It is advisable to take preventive measures to protect solar panels from such animal interference.

- Q:My family has been interested in solar technology for a long time. I want to know how to save money so I can get as many solar panels as possible. I know the government has different discounts/ grants, and there may be tax incentives. I am not looking to sell energy to the energy company I want to use the energy directly.

- Nothing good comes from the government ,nothing .so why would you think they would really help in this matter . If the government is involved , that is a good indicator to stay away.

- Q:I want to install a solar panel on my car. I want to know that how much energy can be generated by a panel of size 4 foot by 6 foot. and the cost of installation.

- A little more than 0 watts per square foot, so that size panel would generate 250 watts under ideal conditions, which is noon on a sunny but not too hot day, near the equator. That's about /3 horsepower, or the same power as a man working hard. That is larger than needed to keep the battery of the car charged, unless you plan to run a laptop or something off it at night. The power is also too small to power the car for driving. If it's an electric car, you could get maybe another 2 miles per day out of the car, again, under ideal conditions. An RV store might have an idea of how much installation would cost. They would be accustomed to solar panels for RV's, but probably not small cars. A panel of that size would cost perhaps $500-800 just for the panel.

- Q:I'm very interested in how solar panels work. I understand the bigger picture of how it can be used for solar heating or as a generator, but I'm lost at the smaller details. Things like: - Could my computer work on solar? It has a 900 watt power supply (this is excluding monitor/speakers) - if a panel is for example, a 60 watt panel, does this mean it will pump 60 watts a second into a battery? - Does solar heating make the water electrified?

- Solar water heating is low technology. There are do it your self plans for it all over the internet. There is no electricity involved. Simply laying a garden hose on the ground in the hot Sun can heat the water to really high temperatures. Just have a shutoff nozzle on the hose, turn on the tap and open the nozzle until water comes out and then close the nozzle at the end of the hose. Let the hose full of water sit in the sun for an hour or so and then open the nozzle and feel how hot the water is that comes out. Be careful, because it can be so hot you can get a burn! When the gallon or so that can fit in the hose has all come out and is replaced by other water from the tap, it will feel cold again. Close the nozzle and wait another hour to heat it up again. A solar hot water heater is just a very long coil of pipe in the Sun, maybe with a pump to slowly circulate water from a holding tank so you can make and store more hot water that fits in the hose. Solar electric power is completely different. It uses semiconductor devices called solar cells to make electricity directly from light. Many of solar cells are usually arranged into large panels to make larger amounts of power. In electricity, Watts = Volts * Amps. Battery capacity is usually measured in Amp-hours. Small solar panels are often designed to produce electricity at 2 volts. A 60 Watt, 2 volt panel makes 5 Amps of electric current, because 2*5=60. So if you use it to charge a 2 volt battery with a capacity of 5 Amp-hours it will take hour to charge. A 0 Amp-hour battery would take 2 hours to charge with the same panel.

- Q:Can solar panels be used in areas with high levels of rainfall?

- Yes, solar panels can be used in areas with high levels of rainfall. Rainfall does not necessarily affect the functioning of solar panels as they primarily rely on sunlight to generate electricity. However, it is important to ensure that the solar panels are properly installed and maintained to prevent any water damage or reduced efficiency caused by excessive rain.

- Q:What is the most affordable, yet highest watt solar panels available?

- Those two requests are somewhat at odds with each other. Trina and Suntech make panels that are generally good value. You can search the web and find your best price. If this is for something that does not need to last long, you could get amorphous panels and save some money. But they will degrade quickly in a few months, then slowly over a few years.

- Q:I contend:As far as the solar panels causing global warming I'll try to explain. If you put a black panel on the ground or on your house and don't connect it to anything, it will absorb solar energy (heat) during daylight and release it at night (radiation). The net heat gain is zero. If you hook up a solar panel in the same place but hook it up to batteries, charge the batteries during sunlight hours and using that energy to electrically heat the home at night. The panels will absorb solar energy during the day but will convert that to electrical energy in the batteries instead of radiating it back into space at night. The result is a net gain in earth's temperature.Right or wrong?

- Third Law of Thermodynamics (in normal speak): “Not only can you never get ahead, you can’t even break even.” This is a truism that applies to all activities involving energy exchange (and almost everything else as well). Energy in the form of solar radiation falls on the earth. That energy is absorbed by the planet (everything) and heat results. Some portion of that energy is lost in the absorption process and the net released as heat is less than that absorbed from the sun. This is true in all cases. Solar panels, both photovoltaic and heat collectors are subject to the Third Law and they all lose some of the radiant energy striking them in the process of converting that energy into either hot water (or whatever fluid) or electrical energy. Regardless of the process there is always a net loss of energy. The time delay you mention has no bearing on the total heat gain or loss for the planet. In fact the “solar panel effect” reduces the net energy put back into the ecosystem because it introduces another iteration of energy loss through conversion. The Holy Grail of energy conservation it the ability to use, store or recover the entire amount of energy produced regardless of the source of that energy, burning hydrocarbons, geothermal heat exchange, solar radiation, mice on treadmills …..all forms of energy suffer a net loss in any exchange! If we could avoid that loss we could dramatically reduce the heat lost into the atmosphere or ground water and our net energy gain would also be dramatic! Check out the super cooled circuits in use to reduce resistance in sophisticated electronic equipment for a good example of the energy savings. (Of course the savings do not account for energy lost in the cooling process. In any event NO….. solar panels do not contribute to global warming via their operation. (Their manufacture is another story altogether!)

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

315W Polycrystalline silicon solar panels

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200000 watt

- Supply Capability:

- 20000000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords