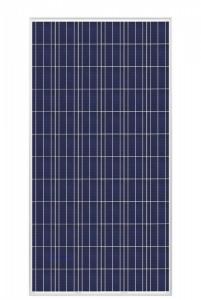

315W Polycrystalline Silicon Solar Panel

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200000 watt

- Supply Capability:

- 20000000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

About us

We are a high-tech group wich specializes in solar products design,research, manufacture, sales,solar projects design and installation.

Our national sales service covers seven parts, including northeast, north, east, middle, south, northwest and southwest, international sales covers five continents and over forty countries, including Germany, Italy, Spain, France, America and Brazil etc.

Our present annual capacity is 6 million for wafer, 60MWp for solar cells,200MWp for solar modules and one hundred thousand for solar applications. It is expected that the annual capacity of 2012 will be up to 30 million for wafer, 300MWp for solar cells, 1000MW for solar modules and 2 million for solar applications.

Solar cell module production process

Line called packaging line components, packaging is the production of solar cells a key step in the packaging process without a good, multi-well battery is also not a good component of production boards. Battery package not only the battery life is guaranteed, but also to enhance the combat strength of the battery. Product quality and high service life is to win can be the key to customer satisfaction, so the quality of components of the package board is very important.

Process is as follows:

1, the battery test

2, positive Welding - Inspection –

3, on the back of cascading - Inspection –

4, laying (glass cleaning, material cutting, glass pre-processing, laying) –

5, laminating –

6, to flash ( to the side, cleaning) –

7, fitted border (glue, loading angle keys, punching, install box, scrub I glue) –

8, the welding junction box –

9, high-pressure test –

10, component testing -- -

11 appearance inspection, packaging and storage;

Data sheet

Maximum power | 315W |

Cell type(mm) | Polycrystalline solar cell 156*156 |

Number of cell(pcs) | 72(6*12) |

Manufacture site | China |

Open-circuit voltage(voc) | 45.1V |

Maximum power voltage(vmp) | 37.3V |

Short-circuit current(isc) | 8.88A |

Optimum operating current(imp) | 8.45A |

Power tolerance | 0~+5W |

Module efficiency | 16.2% |

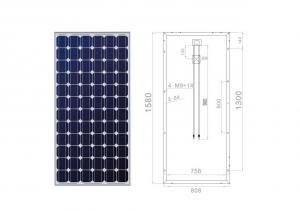

Dimensions(mm) | 1956*992*40 |

Weight | 27 kg |

Backsheet | Silver |

Frame Colar | White |

Frame | Anodized Aluminum Alloy |

FAQ:

1. How long will my inquiry get response?

Your inquiry related to our products or prices will be replied within 24 hours.

2. Can I get professional service and suggestion?

Well-trained and experienced staffs to answer all your questions in fluent English.

3. Do you accept OEM or customized design?

OEM & ODM, any your customized lightings we can help you to design and put into product.

4. What if I need specific design?

Distributorship are offered for your unique design and some our current models.

- Q:I have a cabin in the woods and need more light. I do have enough sun but I was wondering how or where do I get a solar panel to lead to a power outlet? In a perfect world I would like to get a solar panel with a connecting wire to an outlet or something so I could power a small TV. I know its hard enough but can I get that pre-made? Or even lastly should I look at wind power consider I would like this to be under $500? Thank you for putting up with this bundle of questions.

- First okorder /

- Q:How do solar panels affect the environment?

- Solar panels have a positive impact on the environment as they produce clean and renewable energy, reducing the need for fossil fuels. They help decrease greenhouse gas emissions, air pollution, and water usage associated with traditional energy sources. However, the production and disposal of solar panels can have some environmental impact, including the use of certain materials and energy during manufacturing. Overall, their benefits outweigh the potential drawbacks.

- Q:what kind of degree do i need to get in order to know everythin about installing solar panels for houses?

- The only degree you will need is a degree in hard knocks.You will get it from a reliable contractor who has the skill and knowledge with the product.You may want to call the manufacture and see if there any in house schools that you could attend and be certified in their product.

- Q:i have a calculator with a solar panel what could i power with it? like could i hook it up to a psp even though it will take forever to charge? and how would i do this?

- take a look at the back of the psp, most rechargeable things have technical specifications for what kind of charger to use, like the voltage, the amps, and the wiring

- Q:Any feedback on solar panels?

- Solar panels really works good and reduce the usage of electricity.

- Q:Can solar panels be installed on a shaded roof?

- Yes, solar panels can be installed on a shaded roof. However, it is important to note that shade can significantly reduce the overall efficiency and performance of solar panels. Therefore, it is advisable to assess the extent and duration of shade on the roof before installing solar panels to ensure optimal energy generation. Additionally, alternative solutions such as ground-mounted systems or removing nearby obstructions may be considered to maximize solar panel efficiency.

- Q:I'm very interested in how solar panels work. I understand the bigger picture of how it can be used for solar heating or as a generator, but I'm lost at the smaller details. Things like: - Could my computer work on solar? It has a 900 watt power supply (this is excluding monitor/speakers) - if a panel is for example, a 60 watt panel, does this mean it will pump 60 watts a second into a battery? - Does solar heating make the water electrified?

- Build okorder /

- Q:Hi.How efficienent are solar panels? I mean, suppose we install a kw panel.. Wil it produce 5kw in 5 hours of good sun light?Or like if its 80 percent efficient, wil it produce 4kw and so on.Also, do the chinese solar panels give the same results as compared with panels from other countries?I live in india, so we get plenty of sunlight during the day.Thanks

- Panels okorder

- Q:Can solar panels be used in areas with high levels of snowfall?

- Yes, solar panels can still be used in areas with high levels of snowfall. While snow accumulation on the panels can temporarily reduce their efficiency, modern solar panel designs and technologies have improved to withstand heavy snow loads. Additionally, the angle at which solar panels are installed and their smooth surface can help snow easily slide off, allowing them to continue generating electricity even in snowy conditions.

- Q:Can solar panels be used in areas with high levels of pollution from industrial activities?

- Yes, solar panels can be used in areas with high levels of pollution from industrial activities. While pollution can have some impact on the efficiency of solar panels, they are still able to generate electricity even in polluted areas. Regular cleaning and maintenance of the panels may be required to ensure optimal performance. Additionally, installing solar panels in such areas can help offset some of the carbon emissions from industrial activities, contributing to a cleaner and more sustainable energy future.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

315W Polycrystalline Silicon Solar Panel

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200000 watt

- Supply Capability:

- 20000000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords