310w Polycrystalline Silicon Solar Panels

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200000 watt

- Supply Capability:

- 20000000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

About us

We are a high-tech group wich specializes in solar products design,research, manufacture, sales,solar projects design and installation.

Our national sales service covers seven parts, including northeast, north, east, middle, south, northwest and southwest, international sales covers five continents and over forty countries, including Germany, Italy, Spain, France, America and Brazil etc.

Our present annual capacity is 6 million for wafer, 60MWp for solar cells,200MWp for solar modules and one hundred thousand for solar applications. It is expected that the annual capacity of 2012 will be up to 30 million for wafer, 300MWp for solar cells, 1000MW for solar modules and 2 million for solar applications.

INTRODUCTION

This installation Manual contains essential information for the electrical and mechanical installation that your must know before installing CUSTOMER PV modules. This also contains safety information you need to be familiar with .All the information described in this manual are the intellectual property of CNBM and based on the technologies and experiences that have been acquired and accumulated in the long history of CUSTOMER. This document does not constitute a warranty, expressed or implied.

CUSTOMER does not assume responsibility and expressly disclaims liability for loss, damage, or expense arising out of in anyway connected with installation, operation, use or maintenance of the PV modules. No responsibility is assumed by CUSTOMER for any infringement of patents or other rights of third parties that may result from use of PV module.

CUSTOMER reserves the right to make changes to the product, specifications or installation manual without prior notice.

SITE SELECTION

In most applications, the PV modules should be installed in location where there is no shading throughout the year. In the Northern Hemisphere, The PV modules should typically face south, and in the Southern Hemisphere, the PV modules should typically face north. Please make sure that there are no obstruction in the surroundings of the site of installation. Take proper steps in order to maintain reliability and safety, in case the PV modules are used in areas such as: Heavy snow areas/Extremely code areas/ Strong wind areas/Installation over, or near, water/ Areas where installations are prone to salt water damage (*)/Small islands or desert areas.(*)

If you are planning to use the PV modules where the salt water damage may be possible consult with CNBM local agent first to determine an appropriate installation method, or to determine whether the installation is possible?

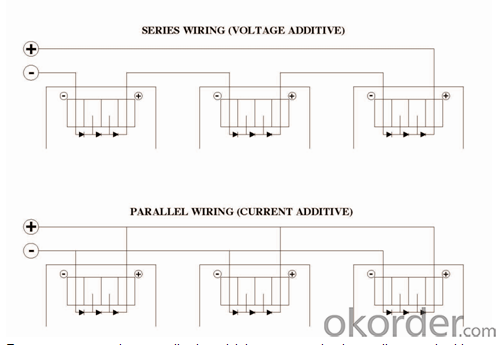

WIRING

To ensure proper system operation to maintain your warranty, observe the correct cable connection polarity(Figures 1&2) when connecting the modules to a battery or to other modules. If not connected correctly, the bypass diode could be destroyed.

PV modules can be wired in series to increase voltage. Connect wires from the positive terminal of one module to the negative of the next module. Figure shows modules connected in series .

Data sheet

Maximum power | 310W |

Cell type(mm) | Polycrystalline solar cell 156*156 |

Number of cell(pcs) | 72(6*12) |

Manufacture site | China |

Open-circuit voltage(voc) | 45V |

Maximum power voltage(vmp) | 37V |

Short-circuit current(isc) | 8.8A |

Optimum operating current(imp) | 8.38A |

Power tolerance | 0~+5W |

Module efficiency | 16% |

Dimensions(mm) | 1956*992*40 |

Weight | 27 kg |

Backsheet | Silver |

Frame Colar | White |

Frame | Anodized Aluminum Alloy |

- Q:i trying to make a solar panel. right now i dont have money to go and buy a copper sheet. so can i make it out of aluminum foil. if there is a way please tell me how. and what do i use for wires. i making this to charge batteries.

- You can't make a solar panel to generate any reasonable amount of electricity from that. You need a semiconductor to start with, in order to have something that can generate free charge carriers(electrons and holes) from photons. Then you need a junction which can separate the charges. In principle you could make a Shottky Diode solar cell from copper if you could find a doped semiconductor to bond a sheet of it to the copper. To form a decent electric field there should be a significant difference in work functions between the copper and the semiconductor, this will generally require the semiconductor to be doped. On top of this you would need a transparent conductor (most used are things like ITO or other 'TCOs' - Transparent Conducting Oxides) to be the top electrode to inject replacement charges into the semiconductor to replace the effect of recombination current. In summary, it's difficult to DIY. You generally need complicated machinery to get decent crystal growth and/or doping.

- Q:Thinking about getting a solar panel installed but i'm worried about getting the govt. rebates. There is a Federal Tax credit and a State of Florida rebate and i'm wondering what the time frame is for getting the rebates. Has anyone gotten a solar panel installed recently that could give me more info.Thanks!

- In case you hadn't heard the state is broke.

- Q:Can solar panels be installed on a hospital or healthcare facility?

- Yes, solar panels can be installed on a hospital or healthcare facility. Installing solar panels on such facilities can help reduce carbon emissions and energy costs, while also providing a reliable and sustainable source of electricity. Additionally, the use of solar energy aligns with the healthcare industry's commitment to promoting environmental sustainability and reducing the overall carbon footprint.

- Q:how the power output of solar panels fitted to a house can chargenothing on the internet really answers this question, any information will really help..this is for GCSE, i don't really understand the meaning of the question. does it ask how the solar panel egts charged, and how it works? i don't get how you can charge a solar panel and is heat the only way you can produce electricity for it??please answer if you know! much appreciated!!! thank you so so so so so so so much, in advance =)

- Solar panels do NOT get charged, so the question is junk, or you misstated it. Solar panels are used to charge a battery bank, which stores energy for times when there is no sun. Then energy from the batteries is used, via an inverter, to power appliances in the house. OR do you mean how the power output of solar panels can CHANGE? In that case, they change when the sun moves, such as behind a cloud, or just changes angle in the sky, or goes out.

- Q:I am starting to think about solar panels as an option for my home. I have done some research on panels, to be honest its all very confusing. There are many different panels some with 60 watts some all the way up to 20 watts. My household currently uses about 2700 to 3400 kWh every two months. So based off of my power usage maybe you can answer some of the following questions:What kind of panels should I be looking at?Which panel manufacturers give the best bang for the buck (reliable/affordable)?Anything else I should be concerned about?I am just starting out in educating myself on solar power so please excuse me if I sound very naive. Any information that you may have will be helpful. Thanks in advance.

- Unfortunately, I can't give you a lot of specifics on what you should use. However, I can tell you that the very best system for you simply might not be available to you, in which case it really doesn't matter how good it is. Your best bet would be to talk to a supplier in your area and see what is available, THEN start looking at the differences between those. Unfortunately, solar panels aren't quite to the point of being a common-place product...yet. Another thing to consider would be how old your roof is. You might want to look into the possibility of building-integrated materials if you are in need of a new roof. Talking with somebody who sells the panels in your area will help you understand a lot more than just doing raw research. Get their take on it, then fact check and research what they tell you so you know you're not getting ripped off.

- Q:How much would it cost to make an average size house be able to depend on solar panels for all of its power?How many solar panels would you need and wear would you put them? Would the roof be large enough to support the panels needed?Do solar panels work well in higher latitudes like northern USA or southern Canada? Can you power your house for the whole year if you live in these environments? What kind of maintenance do solar panels require?

- there are maximum of variables that would make your equipment greater or much less of a good investment. I even have had a equipment for a pair years and that i'm very happy with them. I distinctly propose you get a no legal duty quote, any respected photograph voltaic installation business enterprise would be prepared to try this. I actually have a 2 tale homestead with a pool (pump is one in all my great potential purchasers) in sunny CA and characteristic great orientation, and no coloration on the section. I have been given a three.seventy 4 kw equipment (20 panels i think of) that fee $26K, I gained a $0K rebate from my application and a $2K fed tax credit (at the instant the tax credit on the comparable equipment is $7800) i became into projected to break inspite of my utilization in 7.2 years, it would desire to be faster in view that my city has raised expenses via 20% interior the previous 2 years. The equipment produces approximately ninety% of my summer season utilization and approximately 50% of my wintry climate utilization.

- Q:Do solar panels require a specific type of wiring or electrical setup?

- Yes, solar panels require a specific type of wiring and electrical setup. They need to be connected in series or parallel configurations to form a solar array, and the wiring should be sized appropriately to handle the current produced by the panels. Additionally, an inverter is typically required to convert the DC power generated by the panels into AC power that can be used in homes or businesses. Proper grounding and safety measures must also be considered during installation.

- Q:Can solar panels be used in multi-story buildings?

- Yes, solar panels can be used in multi-story buildings. They can be installed on rooftops or other suitable areas to generate renewable energy for the building.

- Q:What are the different types of solar panels?

- There are three main types of solar panels: monocrystalline, polycrystalline, and thin-film. Monocrystalline panels are made from a single crystal structure, making them highly efficient but also more expensive. Polycrystalline panels are made from multiple crystal structures, offering a slightly lower efficiency but a more affordable price. Thin-film panels are made by depositing a thin layer of semiconductor material onto a substrate, making them flexible and lightweight, but with lower efficiency compared to crystalline panels.

- Q:3.8 volts is required to fully charge a battery. But at 3.8 volts, the battery can be overcharged without the use of a controller correct? What if I don't care if the battery is fully charged? In the case of our family boat, I just installed a new radio, so I'm a little worried about power consumption. So now for the real question; If I hook a 2 volt panel to the batteries, do I need to worry about overcharging them? Or will the batteries stop the charging process once they reach 2 volt?I built the panel myself, it's 8 volts at 3.5 amps open circuit. I have tabs at every 3 volt increment on the panel so that I can use less voltage than 8 if I want to power something directly, (ex:2 volt radio)So I'm using the 2 volt tab at 3.5 amps(approx) for a total of approx 48 watts

- I have been using solar panels for over ten years never until recently bothered to use a charge controller, it depends really on how much power your batteries can hold how often they will be drained from use of the connected dc-ac inverters. While constant daylight charging at 8v 3.5a/hr is quite heavy it is not excessive, 2v lead acid battery chargers give a voltage output of appx 4.8v but the fluctuating output of a solar panel means you may well charge at 8v for some time but with occasional shade etc it will more likely average at 5v which I think is quite acceptable.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

310w Polycrystalline Silicon Solar Panels

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200000 watt

- Supply Capability:

- 20000000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords