310S Stainless Steel Sheet Price per ton

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

430 201 304 321 316L 310S 2507 317L 904L 2205 Hard Stainless Steel Sheet Price Per Kg

Type | 430 201 304 321 316L 310S 2507 317L 904L 2205 Hard Stainless Steel Sheet Price Per Kg |

Thinckness | Hot rolled: 3.0mm-20mm |

Widthness | 1000-2000mm or as customized |

Length | 1000mm-6000mm |

Finish | 2B, BA, HL, Mirror, NO1,NO 4, 8K |

Standard | ASME, ASTM, EN, BS, GB, DIN, JIS |

Material | mainly:201, 202, 304, 304L, 316, 316L,316 300series:301,302,303,304,304L,309,309s,310,310S,316,316L,316Ti,317L,321,3 200series:201,202,202cu,204 400series:409,409L,410,420,430,431,439 |

Application range | Decoration Industry Kitchenwave Building Elevator Upholstery |

Delivery time | 10-15 days subject to the clients' requirement and quantity |

Productivity | 3000 tons/month |

Note | We can produce other standard as the customers’ requirement |

| Surface | Definition | Application |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

| 2B | Those finished, after cold rolling, by heat treatment,pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry,Construction material, Kitchen utensils. |

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction,Medical equipment. |

| HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size | Building Construction. |

| BA(No.6) | Those processed with bright heat treatment after cold rolling. | Kitchen utensils. Electric equipment,Building construction. |

| Mirror(No.8) | Shinning like a mirror | Building construction |

No. | Grade | Chemical Composition % | ||||||||||

C | Cr | Ni | Mn | P | S | Mo | Si | Cu | N | Other | ||

201 | 1Cr17Mn6Ni5N | ≤0.15 | 16.00-18.00 | 3.50-5.50 | 5.50-7.50 | ≤0.060 | ≤0.030 | - | ≤1.00 | - | ≤0.25 | - |

2205 | 00Cr22Ni5Mo3N,S31803 | ≤0.030 | 21.00-23.00 | 4.50-6.50 | ≤2.00 | ≤0.030 | ≤0.020 | 2.5-3.5 | ≤1.00 | - | 0.08-0.2 | |

202 | 1Cr18Mn8Ni5N | ≤0.15 | 17.00-19.00 | 4.00-6.00 | 7.50-10.00 | ≤0.060 | ≤0.030 | ≤1.00 | - | ≤0.25 | - | |

204 | 03Cr16Mn8Ni2N | ≤0.030 | 15.00-17.00 | 1.50-3.50 | 7.00-9.00 | 0.15-0.30 | ||||||

301 | 1Cr17Ni7 | ≤0.15 | 16.00-18.00 | 6.00-8.00 | ≤2.00 | ≤0.065 | ≤0.030 | - | ≤1.00 | - | - | - |

304 | 0Cr18Ni9 | ≤0.07 | 17.00-19.00 | 8.00-10.00 | ≤2.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | - | - | - |

304L | 00Cr19Ni10 | ≤0.030 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | - | - | - |

310S | 0Cr25Ni20 | ≤0.08 | 24.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | - | - | - |

316 | 0Cr17Ni12Mo2 | ≤0.08 | 16.00-18.50 | 10.00-14.00 | ≤2.00 | ≤0.035 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | - | - |

316L | 00Cr17Ni14Mo2 | ≤0.030 | 16.00-18.00 | 12.00-15.00 | ≤2.00 | ≤0.035 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | - | - |

431 | 1Cr17Ni2 | 0.11-0.17 | 16.00-18.00 | 1.50-2.50 | ≤0.80 | ≤0.035 | ≤0.030 | - | ≤0.80 | - | - | - |

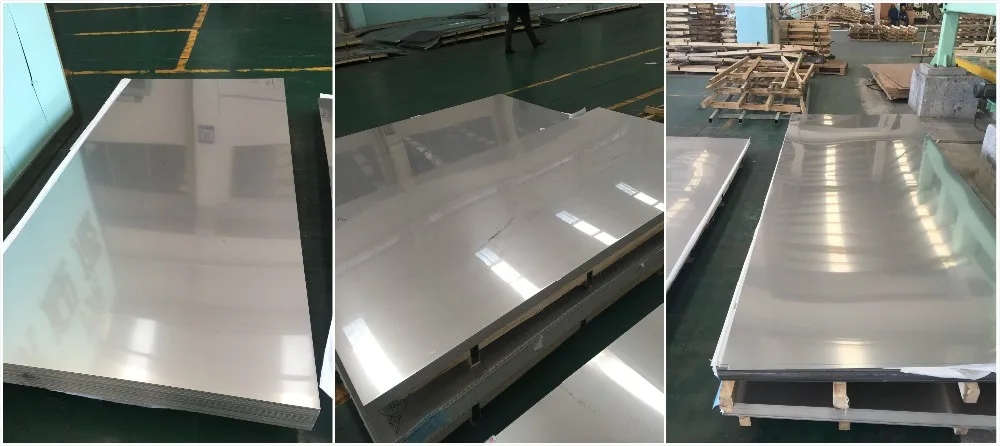

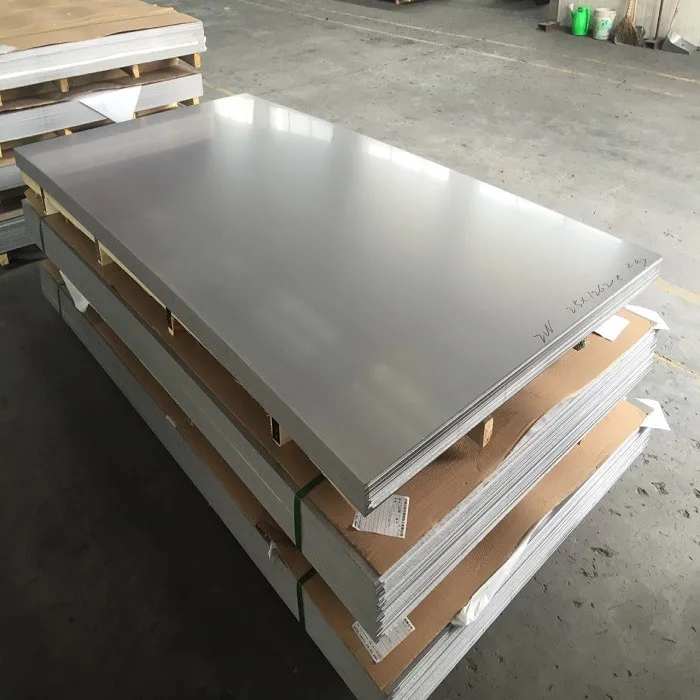

Shows of products

Printing processing

simple process of stainless steel

1.GRINDING

Grinding finish, also called brushed, directional or satin finish. coil or sheet...

2.POLISHING

polished stainless steel sheet uses grinding fluid to polish by polishing equipment on stainless steel ..

3.PVD COLOR COATING

PVD means Physical Vapor Deposition,working in vacuum condiction.....

4.ETCHING

Etching is corrode different kinds of patterns on stainless steel surfaces by chemical methods.

5.EMBOSSING

It is physical rolling on the stainless steel surface, pattern comes from metal roller....

Related Products

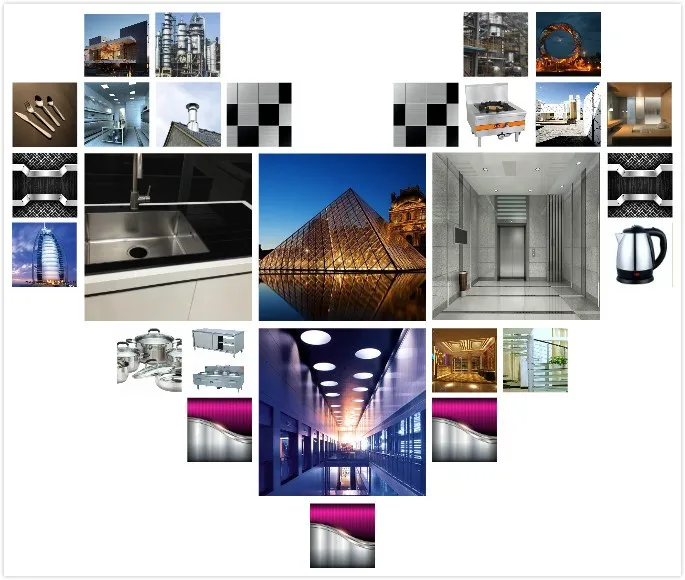

Applications

Stainless steel is widely used such as elevator decoration, luxurious doors, outdoor projects, wall decoration, advertisement nameplates, sanitary ware, ceiling, corridor, hotel hall, shop facade,kitchenware, food industry, electronic industry, medical equipment, etc.

Packaging & Shipping

Standard export package with water proof paper, and metal pallet, and angle bar protection, and steel strip or as required

20ft GP: 5.8m(length) x 2.13m(width) x 2.18m(high) about 24-26CBM, 23MTS

40ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about 54CBM, 27MTS

40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high) about 68CBM, 27MTS

MOQ | 1 Ton |

Price Term | FOB CIF |

Payment | L/C at sight or 30% TT as deposit |

Delivery Time | 20-30 days after receiving deposit by T/T or L/C. |

Sample | Samples free and express charges bear by you |

- Q:Can stainless steel sheets be used for railway infrastructure?

- Yes, stainless steel sheets can be used for railway infrastructure. Stainless steel is known for its durability, corrosion resistance, and strength, making it suitable for various applications in the railway industry. It can be used for railway tracks, bridges, platforms, and other structures that require high strength and long-lasting performance. Additionally, stainless steel's low maintenance requirements and ability to withstand harsh environmental conditions make it an ideal choice for railway infrastructure.

- Q:Can stainless steel sheets be used for hygienic environments?

- Yes, stainless steel sheets are commonly used in hygienic environments due to their inherent properties such as resistance to corrosion, ease of cleaning, and ability to withstand high temperatures. These sheets are frequently used in various industries, including healthcare, food processing, and pharmaceuticals, to ensure a clean and sterile environment.

- Q:Can stainless steel sheets be used for insulation?

- Typically, stainless steel sheets do not serve as insulation materials. Despite being widely used for their durability and resistance to corrosion and heat, stainless steel lacks good insulation properties. The purpose of insulation materials is to minimize heat transfer by reducing conduction, convection, and radiation. These materials usually possess low thermal conductivity, making them effective in preventing heat transfer. On the contrary, stainless steel has high thermal conductivity, allowing it to easily conduct heat. To achieve insulation, it is more common to utilize materials like fiberglass, mineral wool, foam boards, or reflective barriers. These materials have lower thermal conductivity and can effectively trap air or create a barrier that restricts heat transfer. In comparison, stainless steel sheets cannot provide the same level of insulation as these specialized materials. Nevertheless, stainless steel sheets still find utility in construction or industrial settings due to their strength, corrosion resistance, and aesthetic appeal.

- Q:How do you determine the weight of a stainless steel sheet?

- To determine the weight of a stainless steel sheet, you need to consider its dimensions, thickness, and density. The first step is to measure the length, width, and thickness of the sheet using a measuring tool such as a ruler or caliper. Make sure to measure in the same unit of measurement, such as inches or millimeters, to ensure accuracy. Next, you need to determine the density of stainless steel. Stainless steel has a density of around 7.9 grams per cubic centimeter (g/cm³) or 7900 kilograms per cubic meter (kg/m³). This value may vary slightly depending on the specific grade or alloy of stainless steel being used. Once you have the dimensions and density, you can calculate the weight using the formula: weight = volume × density. To find the volume, multiply the length by the width and the thickness. For example, if you have a stainless steel sheet that measures 1 meter by 1 meter and has a thickness of 2 millimeters, the volume would be 0.001 cubic meters (1m x 1m x 0.002m). Using the density of stainless steel (7900 kg/m³), you can then calculate the weight by multiplying the volume by the density. In this example, the weight of the stainless steel sheet would be 7.9 kilograms (0.001m³ x 7900 kg/m³). It is important to note that this calculation will provide an approximate weight as it assumes a uniform thickness throughout the entire sheet. Additionally, variations in composition or manufacturing processes may lead to slight deviations in the density of the stainless steel, which can affect the accuracy of the weight calculation.

- Q:Can stainless steel sheets be used for oil and gas pipelines?

- Indeed, oil and gas pipelines can utilize stainless steel sheets. The oil and gas industry frequently relies on stainless steel because it possesses remarkable resistance against corrosion. It can endure the demanding circumstances involved in the transportation and storage of oil and gas, encompassing high pressure, high temperature, and corrosive surroundings. When constructing pipeline components like pipes, fittings, and flanges, stainless steel sheets are commonly employed. They provide longevity, robustness, and the ability to resist corrosion, thereby aiding in leak prevention and the preservation of pipeline integrity.

- Q:What are the common manufacturing standards for stainless steel sheets?

- There are several common manufacturing standards for stainless steel sheets that ensure their quality and consistency. One of the most widely recognized standards is the ASTM International (formerly known as the American Society for Testing and Materials) standard. ASTM A240 is the specific standard for stainless steel sheets, which specifies the requirements for chemical composition, mechanical properties, and other relevant characteristics of the material. Another important manufacturing standard is the EN (European Norm) standard, specifically EN 10088, which provides guidelines for stainless steel flat products, including sheets. This standard covers various aspects such as dimensions, tolerances, surface finishes, and more. Additionally, there are national standards developed by different countries. For example, in Japan, the Japanese Industrial Standards (JIS) classify stainless steel sheets under various specifications such as JIS G4304 and JIS G4305. These standards define the requirements for chemical composition, mechanical properties, and surface finishes of stainless steel sheets. In the United States, the American Iron and Steel Institute (AISI) also sets standards for stainless steel sheets. The AISI 300 and 400 series are commonly used in the manufacturing of stainless steel sheets, and their properties are defined by the AISI. It is important for manufacturers and suppliers to adhere to these standards to ensure that the stainless steel sheets meet the desired quality requirements and can be used reliably in various applications. These standards help maintain consistency, compatibility, and traceability in the production and use of stainless steel sheets across different industries.

- Q:What are the different types of edge finishes available for stainless steel sheets?

- Stainless steel sheets can be finished with various edge treatments to achieve different appearances and functionalities. These finishes serve to enhance the sheet's aesthetics, protect against sharp edges and potential corrosion. 1. Mill Finish: The standard edge finish for stainless steel sheets is the raw, untreated edge produced during manufacturing. While it may have a slightly rough or uneven appearance, it is functional and commonly used in industrial applications. 2. Deburred Edges: To eliminate any sharp or jagged edges, the stainless steel sheet can undergo deburring. This involves grinding or sanding down the edges to create a smoother and safer finish. Deburred edges are commonly chosen in safety-sensitive applications like food processing or medical equipment. 3. Rounded Edges: Rounded edges are achieved by utilizing a rounding tool to smooth out the sharp corners of the stainless steel sheet. This finish not only enhances the sheet's aesthetics but also reduces the risk of injury from sharp edges. Rounded edges are often favored for architectural or decorative purposes. 4. Beveled Edges: By cutting or grinding the edge of the stainless steel sheet at a specific angle, typically 45 degrees, beveled edges are created. This chamfered edge adds a sleek and modern appearance to the sheet. Beveled edges are commonly used in applications where aesthetics and design are important, such as furniture or interior design. 5. Polished Edges: Polished edges involve buffing or polishing the edge of the stainless steel sheet to achieve a smooth and mirror-like finish. This edge treatment adds a touch of elegance and sophistication, making it suitable for high-end architectural or decorative applications. To sum up, stainless steel sheets can be finished with mill finish, deburred edges, rounded edges, beveled edges, or polished edges. Each finish offers its own unique benefits and is chosen based on the specific requirements of the application.

- Q:Can stainless steel sheets be used for countertops or backsplashes?

- Certainly! Countertops and backsplashes can indeed be made from stainless steel sheets. This material is highly durable and can resist stains, heat, and bacteria, which makes it an exceptional option for kitchen surfaces. It is simple to clean, maintains its appearance throughout time, and can endure heavy usage. Not only are stainless steel countertops and backsplashes widely used in commercial kitchens because of their hygienic qualities, but they are also gaining popularity in residential settings due to their stylish and contemporary appearance.

- Q:What are the costs of stainless steel sheets compared to other materials?

- The costs of stainless steel sheets tend to be higher compared to other materials such as aluminum or carbon steel. This is primarily due to the higher production and fabrication costs associated with stainless steel, as well as its superior corrosion resistance and durability, which make it a popular choice for various applications. However, it's important to consider the long-term benefits and value that stainless steel offers, making it a worthwhile investment in many cases.

- Q:How do you calculate the bending radius for stainless steel sheets?

- To calculate the bending radius for stainless steel sheets, you need to consider the material's thickness, tensile strength, and the desired level of bendability. The bending radius can be determined using formulas or tables specific to stainless steel, taking into account these factors to ensure the sheet does not crack or deform during bending.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

310S Stainless Steel Sheet Price per ton

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords