304 Stainless Steel Sheet Direct sale in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description

1. 304 Stainless steel sheet direct detailed introduction :

Description | 304 stainless steel sheet direct. |

Material | 201,202,304,304L,309S,310S,316,316L,316Ti,317L,321,347H,409,409L,410,410S,420,430,etc. |

Thickness | From 0.3mm to 100mm |

Width | 1000mm,1219mm,1250mm,1500mm,1800mm,2200mm or be cut as your requirement |

Length | 2000mm,2438mm,2500mm,6000mm,6096mm or be cut as your requirement |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/mouth |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made according to the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

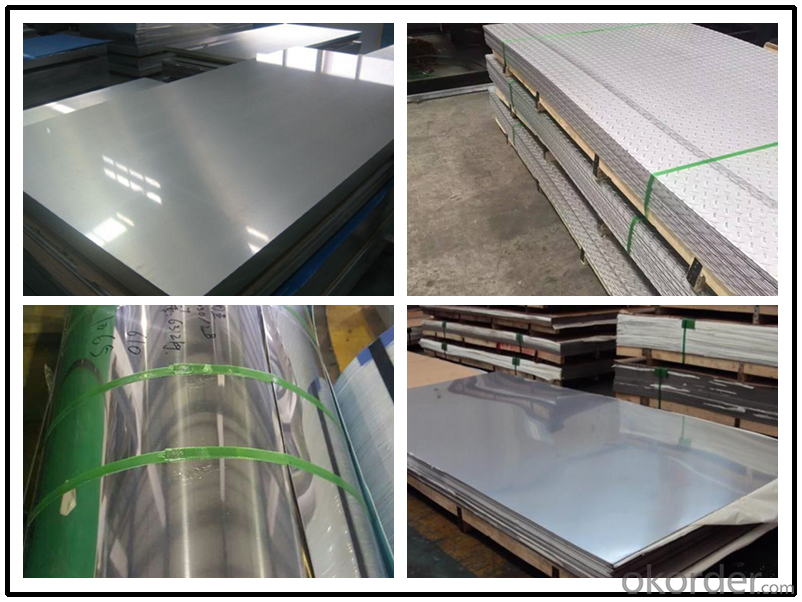

Detailed Images

Packaging & Shipping

Application

- Q:What is the bending strength of stainless steel sheets?

- The bending strength of stainless steel sheets can vary depending on the specific grade and thickness of the sheet. However, stainless steel is generally known for its high strength and rigidity, making it suitable for various applications that require strong and durable materials.

- Q:What are the different shapes available for stainless steel sheets?

- There are several different shapes available for stainless steel sheets, depending on the specific requirements and applications. Some of the most common shapes include: 1. Rectangular sheets: These are the most commonly used shape for stainless steel sheets. They come in various standard sizes and can be easily cut to the desired dimensions. 2. Round sheets: Round stainless steel sheets are often used for decorative purposes or in applications where a seamless or curved surface is desired. They are available in different diameters and thicknesses. 3. Square sheets: Similar to rectangular sheets, square stainless steel sheets are used in a variety of applications. They provide a symmetrical and uniform appearance and can be easily cut to size. 4. Perforated sheets: These sheets have small holes punched through them in a regular pattern. They are commonly used in architectural and industrial applications where ventilation, filtration, or visibility is required. 5. Embossed sheets: Embossed stainless steel sheets have raised or recessed patterns on their surface, adding texture and visual interest. They are often used in interior design, furniture manufacturing, and automotive applications. 6. Expanded metal sheets: These sheets are made by cutting and stretching a solid sheet of stainless steel, creating a grid-like pattern with diamond-shaped openings. They are commonly used for security fencing, walkways, and industrial applications. 7. Checker plate sheets: Also known as tread plate or diamond plate, these sheets have a raised diamond pattern on the surface. They are commonly used for slip-resistant flooring, stair treads, and decorative accents. These are just a few examples of the different shapes available for stainless steel sheets. The choice of shape depends on the specific application, aesthetic preferences, and functional requirements of the project.

- Q:How do stainless steel sheets differ from regular steel sheets?

- There are several key differences between stainless steel sheets and regular steel sheets. Firstly, stainless steel is an alloy that contains a minimum of 10.5% chromium by mass. This chromium content creates a protective passive layer on the steel's surface, preventing corrosion and staining. On the other hand, regular steel sheets are prone to rust and corrosion when exposed to moisture or certain chemicals. Secondly, stainless steel sheets have superior resistance to heat and oxidation compared to regular steel sheets. This makes stainless steel an excellent choice for applications that require high temperature resistance, like industrial furnaces or automotive exhaust systems. Thirdly, stainless steel sheets have exceptional strength and durability, making them suitable for various structural and industrial uses. Regular steel sheets may have lower strength and durability, depending on their composition and manufacturing process. Moreover, stainless steel sheets have an appealing appearance due to their smooth and shiny surface. This aesthetic quality makes them a popular choice in architectural, interior design, and decorative applications. Lastly, stainless steel sheets are known for their hygienic properties. They are non-porous and easy to clean, making them commonly used in industries with strict hygiene requirements, such as food processing, pharmaceuticals, and healthcare. In conclusion, stainless steel sheets differ from regular steel sheets in terms of their corrosion resistance, heat resistance, strength, appearance, and hygiene properties. These unique characteristics make stainless steel sheets the preferred material for many industries and applications.

- Q:What is the maximum operating temperature for stainless steel sheets?

- The maximum operating temperature for stainless steel sheets varies depending on the grade of stainless steel. However, most commonly used grades can withstand temperatures up to 1500-1600°F (816-871°C).

- Q:Can stainless steel sheets be used for hygienic applications?

- Yes, stainless steel sheets can be used for hygienic applications. Stainless steel is known for its excellent hygiene properties due to its non-porous surface, which makes it resistant to bacteria, mold, and other microorganisms. It is also easy to clean and maintain, making it suitable for applications where cleanliness and hygiene are crucial, such as in the food and beverage industry, healthcare facilities, and pharmaceutical manufacturing. Additionally, stainless steel is highly durable, corrosion-resistant, and can withstand high temperatures, making it an ideal material for hygienic applications.

- Q:Are stainless steel sheets suitable for solar panel frames?

- Yes, stainless steel sheets are suitable for solar panel frames. Stainless steel is a strong and durable material that offers excellent corrosion resistance, making it ideal for outdoor applications like solar panel frames. It can withstand harsh weather conditions, including high temperatures, humidity, and UV radiation, without rusting or corroding. Additionally, stainless steel has a high strength-to-weight ratio, allowing it to support the weight of the solar panels while maintaining structural integrity. Its aesthetic appeal and low maintenance requirements also make it a popular choice for solar panel frames.

- Q:Are stainless steel sheets suitable for elevator buttons?

- Yes, stainless steel sheets are suitable for elevator buttons. Stainless steel is a durable and corrosion-resistant material, making it an ideal choice for elevator buttons that are frequently touched and exposed to various environmental conditions. Additionally, stainless steel has a sleek and modern appearance, making it aesthetically pleasing for elevator buttons.

- Q:Are stainless steel sheets suitable for electrical enclosures?

- Yes, stainless steel sheets are suitable for electrical enclosures. Stainless steel has excellent corrosion resistance and durability, making it ideal for protecting electrical components from environmental factors. It provides a high level of protection against water, dust, and other contaminants, ensuring the safety and longevity of the electrical enclosure. Additionally, stainless steel has good electrical conductivity, making it a suitable material for grounding purposes in electrical enclosures.

- Q:How do you remove adhesive residue from stainless steel sheets?

- To remove adhesive residue from stainless steel sheets, you can follow these steps: 1. Start by gently scraping off as much of the residue as possible using a plastic scraper or your fingernail. Be careful not to scratch the stainless steel surface. 2. Next, dampen a soft cloth with warm water and mild detergent or dish soap. Gently scrub the adhesive residue using circular motions. Avoid using abrasive cleaners or scrub brushes as they can damage the stainless steel finish. 3. If the adhesive residue persists, you can try using a non-abrasive cleaner specifically designed for stainless steel. Apply a small amount of the cleaner to a soft cloth and gently rub the residue until it lifts off. 4. For stubborn adhesive residue, you can make a paste using baking soda and water. Apply the paste to the affected area and let it sit for a few minutes. Then, use a soft cloth to gently scrub off the residue in circular motions. 5. Rinse the stainless steel sheet thoroughly with warm water to remove any remaining residue or cleaner. 6. Finally, dry the surface with a clean, soft cloth to prevent water spots and streaks. Remember to always test any cleaning method or product on a small, inconspicuous area of the stainless steel sheet before applying it to the entire surface. This will ensure that it doesn't cause any damage or discoloration.

- Q:What is the price range for stainless steel sheets?

- The price range for stainless steel sheets can vary depending on factors such as size, thickness, and grade of stainless steel. Generally, stainless steel sheets can range from $20 to $200 per sheet, but prices can be higher for specialized or custom-made sheets.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

304 Stainless Steel Sheet Direct sale in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords