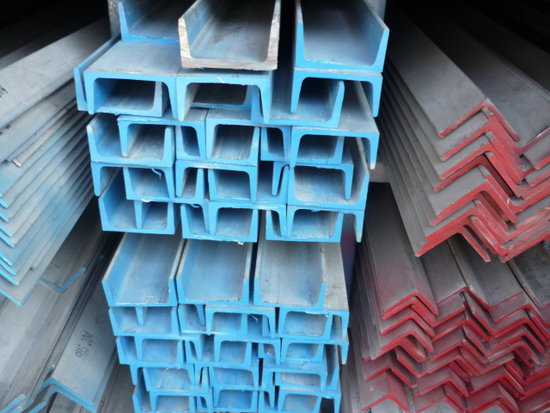

304 Stainless Steel Channel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Channel

1.Size: 3mm to 24mm Thickness

2.Material:SUS201,202,301,304,304L,316,316L ,321 etc.

3.Length: 4m to 6m,or according to the customer's requirement

4.Standard: AISI,JIS,GB,DIN

5.Finish: Cold Drawn ,hot rolled & Polishing

6.Testing: Each heat number and batch must be tested for both chemical and mechanical properties

7.Application: Produce screw and nut, engine parts, indoor and outdoor decorating,etc.

|

Size (mm) |

Thickness (mm) | ||||||||

|

H×B |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

12 |

|

Mass (Kg/m) | |||||||||

|

40×20 |

1.79 |

|

|

|

|

|

|

|

|

|

50×25 |

2.27 |

|

|

|

|

|

|

|

|

|

60×30 |

2.74 |

3.56 |

4.37 |

5.12 |

|

|

|

|

|

|

70×35 |

3.23 |

4.21 |

5.17 |

6.08 |

|

|

|

|

|

|

80×40 |

3.71 |

4.84 |

5.96 |

7.03 |

|

|

|

|

|

|

90×45 |

4.25 |

5.55 |

6.83 |

8.05 |

|

|

|

|

|

|

100×50 |

4.73 |

6.18 |

7.62 |

8.98 |

10.3 |

11.7 |

13 |

41.2 |

|

|

120×60 |

|

|

9.2 |

10.9 |

12.6 |

14.2 |

|

|

|

|

130×65 |

|

|

10.1 |

11.9 |

13.8 |

15.5 |

17.3 |

19.1 |

|

|

140×70 |

|

|

|

12.9 |

14.9 |

16.8 |

18.8 |

20.7 |

|

|

150×75 |

|

|

|

13.9 |

16 |

18.1 |

20.2 |

22.2 |

26.3 |

|

160×80 |

|

|

|

14.8 |

17.1 |

19.3 |

21.6 |

23.8 |

28.1 |

|

180×90 |

|

|

|

16.7 |

19.4 |

22 |

24.5 |

27 |

32 |

|

200×100 |

|

|

|

18.6 |

21.6 |

24.5 |

27.4 |

30.2 |

35.8 |

- Q:Are stainless steel channels resistant to impact or abrasion?

- Stainless steel channels are known for their resistance to impact and abrasion. This is due to the high durability and excellent strength and toughness of stainless steel. The presence of alloying elements like chromium and nickel further enhances the material's ability to withstand impact and resist abrasion, thanks to their corrosion resistance and ability to increase hardness. Moreover, stainless steel channels can be hardened even more through different heat treatment processes, making them exceptionally resistant to impact and abrasion. In summary, stainless steel channels are a dependable option for applications that demand resistance to impact and abrasion.

- Q:How do stainless steel channels perform in earthquake resistance or seismic design?

- Stainless steel channels, being a versatile and durable material, can indeed contribute to earthquake resistance and seismic design. The seismic performance of a structure depends on several factors, including the material properties and the overall design approach. Stainless steel, known for its exceptional strength and corrosion resistance, can provide significant advantages in earthquake-prone regions. Its high tensile strength allows it to withstand the forces generated during seismic events. Additionally, stainless steel exhibits excellent ductility, meaning it can deform under stress without losing its structural integrity. This property is crucial in seismic design as it allows the material to absorb and dissipate energy during an earthquake, reducing the risk of structural failure. Furthermore, stainless steel channels offer design flexibility, enabling engineers to create earthquake-resistant structures with complex geometries and specific load-bearing requirements. The material's resistance to corrosion ensures long-term durability, a crucial factor in areas with high seismic activity where structures may be exposed to aggressive environmental conditions. It is important to note that the seismic performance of stainless steel channels also relies on the overall structural design and the incorporation of appropriate seismic design principles. Adequate bracing, connections, and anchorage systems should be implemented to ensure optimal performance during seismic events. In conclusion, stainless steel channels have proven to be an effective and reliable option for earthquake resistance and seismic design. Their high strength, ductility, and corrosion resistance make them a suitable choice for structures in earthquake-prone regions. However, it is crucial to integrate these channels into a comprehensive seismic design approach to maximize their performance and ensure the safety of the structure and its occupants.

- Q:How long do stainless steel channels last?

- Stainless steel channels have an exceptionally long lifespan, typically lasting for decades or even a lifetime, due to their high resistance to corrosion, durability, and strength.

- Q:How do stainless steel channels contribute to building resilience or durability?

- Stainless steel channels play a crucial role in enhancing the resilience and durability of buildings in several ways. Firstly, stainless steel's unique properties make it highly resistant to corrosion, rust, and staining, which is especially important in areas with high humidity, saltwater exposure, or harsh industrial environments. This resistance ensures that the channels remain structurally sound and functional over extended periods, preventing any weakening or degradation that could compromise the integrity of the building. Furthermore, stainless steel channels offer exceptional strength and load-bearing capabilities. They are capable of withstanding heavy loads, extreme temperatures, and seismic activities, making them ideal for use in high-rise buildings, bridges, and other critical structures. The high strength-to-weight ratio of stainless steel channels allows for the construction of lighter and more efficient designs while maintaining structural integrity. Another significant advantage of stainless steel channels is their fire resistance. Stainless steel has a high melting point and does not combust, making it an excellent choice for fire-resistant construction. In the event of a fire, stainless steel channels can maintain their structural integrity for extended periods, providing additional time for evacuation and reducing the risk of collapse. Additionally, stainless steel channels are known for their low maintenance requirements. Unlike other materials, stainless steel does not require regular painting, coating, or special treatments for protection against corrosion. This not only reduces maintenance costs but also ensures that the channels retain their durability and resilience throughout their lifespan. Lastly, stainless steel channels are environmentally friendly and sustainable. They are fully recyclable, allowing for the reuse of materials and reducing the demand for new resources. Stainless steel's longevity and low maintenance requirements also contribute to the overall sustainability of buildings, as they reduce the need for frequent repairs and replacements. In conclusion, stainless steel channels contribute significantly to building resilience and durability by offering resistance to corrosion, providing high strength and load-bearing capabilities, offering fire resistance, requiring minimal maintenance, and being environmentally friendly. These qualities make stainless steel channels a reliable and long-lasting choice for construction, ensuring the longevity and safety of buildings in various applications.

- Q:What is the impact resistance of stainless steel channels?

- The impact resistance of stainless steel channels is generally high due to their strong and durable nature. Stainless steel is known for its ability to withstand impact and retain its shape, making it suitable for various applications where resistance to physical damage is required.

- Q:Can stainless steel channels be used in railway applications?

- Yes, stainless steel channels can be used in railway applications. Stainless steel is a durable and corrosion-resistant material, making it suitable for various railway components. Stainless steel channels can be used for track supports, bridge structures, signaling and electrification equipment, and other railway infrastructure. They can also be used for interior fittings and fixtures in train carriages. Stainless steel's high strength-to-weight ratio and resistance to extreme temperatures and environmental conditions make it a reliable choice for railway applications. Additionally, stainless steel channels can be easily fabricated and welded to meet specific design requirements, further enhancing their suitability for railway use.

- Q:Can stainless steel channels be used for curtain walls or façade systems?

- Certainly, curtain walls or façade systems can indeed utilize stainless steel channels for their construction. The preference for stainless steel in such applications stems from its ability to withstand wear and tear, its visually pleasing characteristics, and its immunity to corrosion. In terms of functionality, stainless steel channels are capable of providing structural support and acting as framing components for curtain walls or façade systems. By utilizing stainless steel channels, it becomes possible to secure glass or alternative cladding materials, ultimately resulting in a sleek and contemporary appearance. In addition, stainless steel channels can be tailored to meet specific design prerequisites and are obtainable in a range of sizes and finishes. Collectively, stainless steel channels represent a dependable and versatile choice for curtain walls or façade systems.

- Q:What are the different types of reinforcement methods used with stainless steel channels?

- Stainless steel channels can be enhanced in their structural integrity, stability, and load-bearing capacity by employing various reinforcement methods. Welded stiffeners, for example, are commonly used. These additional metal pieces are welded onto the channel to provide extra strength and rigidity. Typically, they are placed at regular intervals along the channel's length, with their size and placement determined by the specific requirements of the application. Another method of reinforcement is bracing. This involves adding diagonal or horizontal members that are connected to the channel to provide additional support. Bracing is particularly useful when the channel is subjected to lateral or bending loads, as it helps distribute the load more evenly. Composite materials can also be used to reinforce stainless steel channels. This involves bonding a layer of carbon fiber or fiberglass to the channel's surface. The composite material adds strength and stiffness while reducing the channel's weight. Internal reinforcement techniques can also be employed. This includes the use of ribs or flanges on the inside of the channel, which aid in load distribution and prevent deformation. Internal reinforcement methods are often necessary when external reinforcement is not feasible due to space limitations. When selecting a reinforcement method for stainless steel channels, factors such as the specific application, load requirements, and cost considerations should be taken into account. Each method has its own advantages and disadvantages, and careful consideration of these factors is essential in choosing the appropriate reinforcement method for a given application.

- Q:Can stainless steel channels be used in outdoor environments?

- Yes, stainless steel channels can be used in outdoor environments. Stainless steel is highly resistant to corrosion and rust, making it an ideal choice for outdoor applications that are exposed to moisture and other harsh elements.

- Q:Are stainless steel channels resistant to impact or vibration?

- Yes, stainless steel channels are generally resistant to impact and vibration. Stainless steel is known for its high strength and durability, making it a suitable material for applications that require resistance to impact and vibration. Additionally, stainless steel has excellent fatigue strength, which means it can withstand repeated loading and unloading without experiencing significant deformation or failure. However, it is important to note that the specific level of resistance to impact and vibration may vary depending on the grade and thickness of the stainless steel channel, as well as the magnitude and frequency of the impact or vibration.

1. Manufacturer Overview |

|

|---|---|

| Location | Qingdao,China |

| Year Established | 2008 |

| Annual Output Value | Above US$100 Million |

| Main Markets | Middle East;Europe;North America |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 0.8 |

| No.of Employees in Trade Department | 100 People |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 60,000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

304 Stainless Steel Channel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords