302/304/316/316L Stainless Steel Woven Wire Mesh with CE, SGS

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Materials: Mild steel wire, brass wire, nickel wire, stainless steel wire, polyester filter.

Materials: SUS 302, 304, 304L, 316, 316L.

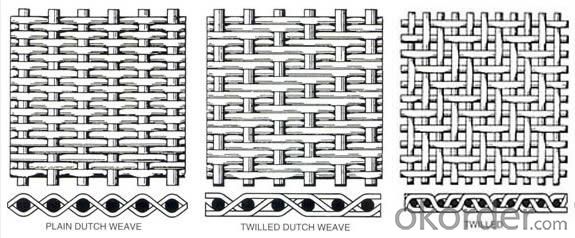

Weave Patterns: Divided Dutch Plain Weaving, Dutch Twill Weaving, Dutch Reverse Weaving, coarsely woven

Characteristic: Good antiwear characteristic, heat-resistance and acid, corrosion resistance.

Use: Stainless Steel Dutch Weave Filter Cloth is utilized as filter fittings for chemical industry, medicine, petroleum, telecom communication, scientific research units etc.

Samples:Availiable

Stainless Steel Wire Mesh and Wire Cloth, Plain Weave | |||

Mesh | Wire Dia. (MM) | Opening (MM) | Material (AISI) |

7meshx7mesh | 1.00 | 2.63 | 304 or316 |

10meshx10mesh | 0.60 | 1.94 | 304 or316 |

12meshx12mesh | 0.50 | 1.62 | 304 or316 |

16meshx16mesh | 0.40 | 1.19 | 304 or316 |

16meshx16mesh | 0.35 | 1.24 | 304 or316 |

18meshx18mesh | 0.35 | 1.06 | 304 or316 |

20meshx20mesh | 0.40 | 0.87 | 304 or316 |

24meshx24mesh | 0.26 | 0.80 | 304 or316 |

30meshx30mesh | 0.30 | 0.55 | 304 or316 |

35meshx35mesh | 0.17 | 0.56 | 304 or316 |

40meshx40mesh | 0.23 | 0.40 | 304 or316 |

50meshx50mesh | 0.20 | 0.31 | 304 or316 |

60meshx60mesh | 0.15 | 0.27 | 304 or316 |

70meshx70mesh | 0.12 | 0.24 | 304 or316 |

80meshx80mesh | 0.13 | 0.19 | 304 or316 |

90meshx90mesh | 0.12 | 0.16 | 304 or316 |

100meshx100mesh | 0.10 | 0.15 | 304 or316 |

120meshx120mesh | 0.09 | 0.12 | 304 or316 |

150meshx150mesh | 0.063 | 0.11 | 304 or316 |

180meshx180mesh | 0.053 | 0.09 | 304 or316 |

200meshx200mesh | 0.053 | 0.07 | 304 or316 |

Stainless Steel Wire Mesh and Wire Cloth, Twill Weave | |||

Mesh | Wire Dia. (MM) | Opening (MM) | Material (AISI) |

250meshx250mesh | 0.040 | 0.063 | 316 |

300meshx300mesh | 0.040 | 0.044 | 316 |

325meshx325mesh | 0.035 | 0.043 | 316L |

350meshx350mesh | 0.030 | 0.042 | 316L |

400meshx400mesh | 0.030 | 0.033 | 316L |

450meshx450mesh | 0.028 | 0.028 | 316L |

500meshx500mesh | 0.025 | 0.026 | 316L |

Stainless Steel Wire Cloth, Dutch Weave | ||

Mesh | Wire Dia. (MM) | Material (AISI) |

12mesh x 64mesh | 0.58 x 0.40 | 304 or 316 |

24mesh x 110mesh | 0.36 x 0.25 | 304 or 316 |

14mesh x 88mesh | 0.50 x 0.33 | 304 or 316 |

30mesh x 150mesh | 0.23 x 0.18 | 304 or 316 |

40mesh x 200mesh | 0.18 x 0.13 | 304 or 316 |

50mesh x 250mesh | 0.14 x 0.11 | 304 or 316 |

80mesh x 700mesh | 0.10 x 0.08 | 304 or 316 |

165mesh x 800mesh | 0.071 x 0.040 | 304 or 316 |

165mesh x 1400mesh | 0.06 x 0.04 | 304 or 316 |

200mesh x 1800mesh | 0.05 x 0.032 | 304 or 316 |

825mesh x 2300mesh | 0.035 x 0.025 | 316L |

400mesh x 2800mesh | 0.030 x 0.02 | 316L |

Width of Stainless Steel Wire Mesh: 0.6m-1.5m

- Q:What is the screen printing plate?

- Screen printing version is called screen, usually nylon fiber material, no stretch before the screen texture is like silk, silk screen is stretched in the use of the box, the box is made of aluminum,

- Q:Screen printing and printing the difference

- ink, pressure and other processes, so that ink transferred to paper, fabric, Leather and other materials on the surface, the bulk copy of the original content of the technology.

- Q:What are the characteristics of screen printing?

- Ink layer thick coverage, for all types of ink, light resistance, flexible printing and diverse

- Q:On the issue of their own screen printing

- Print a colored pattern on a white shirt, I'm now nothing I wanna know what i need ...

- Q:Screen printing, how to choose the screen

- According to the choice of screen printing products mesh mesh, we do plastic products are generally used 300 purposes, the effect will be much better.

- Q:Screen printing, how to print circular arc surface

- To silk screen equipment shop to do a silk screen plate, screen and the same as the normal production, the screen inversion, printing side up, the best version of the screen with a hinge fixed to facilitate up and down tilt.

- Q:The difference between screen printing characteristics

- But also in the ultra-small, ultra-high precision items on the printing, and can also be printed on the surface or spherical, this printing method has great flexibility and wide applicability.

- Q:How to get the correct fishing wire

- Screen (sticky net) used in a narrow place, the best night net, pay attention to the depth of water, the Internet is not too heavy too heavy. Can sink on the line.

- Q:Screen printing has several characteristics

- The principle of stencil printing is: the printing plate (paper version or other version of the foundation to produce through the ink hole) in the printing, through a certain pressure to the ink through the hole version of the hole transferred to the substrate (paper, ceramics

- Q:Screen printing and other printing methods of the difference

- Ink variety, can print a variety of special effects, three-dimensional sense of strong. The printing method is infinitely changing.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

302/304/316/316L Stainless Steel Woven Wire Mesh with CE, SGS

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords