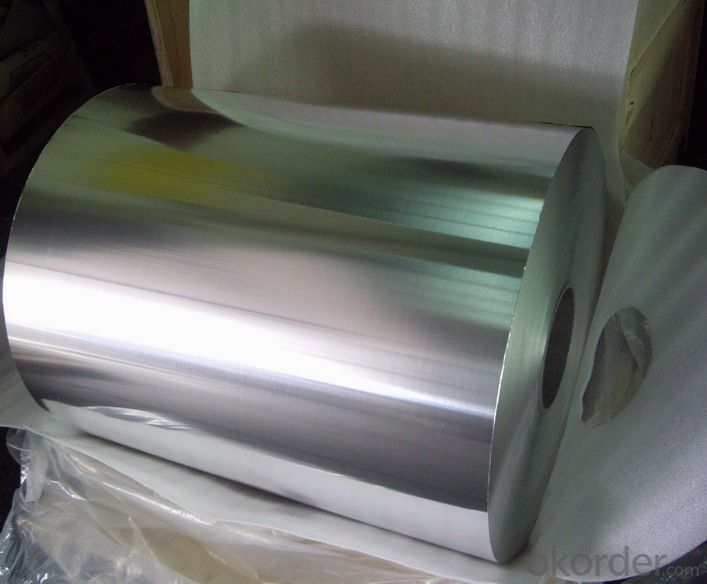

3003 Aluminium Coil And Aluminium Strip Household Aluminium Foil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Specifications

Aluminum foi laminated roll film

1. High tensile strength

2. High glossy print, durable using

3.Diverse styles and low-cost

specifications:

1)excellent performance of anti-hight tenperature:our film neither cracks nor yellows, even when exposed to direct sunlight. It keeps its transparency and preserves aesthetic beauty.our pe film can be dilacerated easily without remaining trails after exposured in the 70oC oven for continuate 48 hours.

2)excellent performance of anti-low tenperature:our pe film can be dilacerated easily without remaining trails after expousured in the -40oC oven for 6 hours.

3)excellent performance of absorption of UV ray:our pe film can be dilacerated easily without remaining trails after expousured in 300w uv or infrared light within 20cm for 48 hours.It protects the displays from getting damaged by UV rays.

4)his series of protective film can help prevent surface from being damaged during transportation.Our film is available in a wide range of size,and possible to select different types as the users's requirement.

5)e will provide consumers with first class quality and perfect service.

Our services

1. Reasonable production arrangement to make delivery very fast;

2. We are able to provide leading tolerances, metallurgical assistance, quick and reliable delivery, samples for new products, etc.

3.We have the strong capability to meet your particular requirement for the products.

4.To guarantee the quality of the products we can meet most of the standards all over the world.

- Q:How many anodized aluminum foils does a standard volume of anodized aluminum foil require?

- Also known as gilt paper, in the early 1930s, the Germans used the gold vacuum attached to the wax coated glass paper method, the first time produced gold foil

- Q:UV printing can also be hot stamping

- Take the sprinkler, sprinkler Ricoh G5 will be more than 20000, while the Toshiba CE4 is only about 6000, Toshiba life of 24-36 months, the printing speed, but the accuracy of the Toshiba CE4 Ricoh than G5 high, Toshiba head warranty of two years, which determines the process of using the printer in the future whether the problem of increasing cost

- Q:What is the principle of anodized aluminum printing of different colors of aluminum layer to the surface of printed matter?

- Anodized hot stamping process are as follows: through hot stamping anodized aluminum version makes the heating, melting and stripping layer, adhesive layer is melted in nano imprint lithography adhesive layer and substrate bonding, the colored layer and the polyester film base from the aluminizing layer and the coloring layer in the substrate.

- Q:What is the working principle of the gilding press?

- Introduction to the working principle and classification of gilding pressThe principle is to have the color of gilding bronzing paper bronzing paper to cover your substrate through the above pressure, time adjustment, glue layer its subsequent stamping paper through temperature and pressure to combine with the substrate, and then through the foil layer and the base layer and some from each other from the rest the glue layer, plating layer, color layer used in your substrate to the above.

- Q:What is the structure of anodized aluminium foil?

- From the opposite to the front substrate, followed by the isolation layer (also called stripping layer), protective layer (also called the colored layer), aluminium layer and adhesive layer.

- Q:Plastic pad hot stamping how to deal with?

- (1) the foil binder does not match the material of the base material. Variety of foil should be replaced.(2) the surface of the product has mould release agent, grinding agent, dust, fingerprint and oil stain. Should use alcohol and other solvents to wipe the surface of the product.(3) the stamping temperature is too low. Should be appropriately improved.(4) the stamping pressure is too small. Should be appropriately improved.(5) the stamping time is too short. Should be appropriately extended.(6) the foil is out of date and the adhesive is invalid. New foil shall be replaced and overdue foil shall not be used.(7) the surface of the hot stamping face has reinforcing ribs or other highly different structures, resulting in uneven stamping pressure.

- Q:What's the reason for the lack of stamping or stamping?

- Printing printing ink layer too thick: color ink layer thick substrate, the substrate surface will prevent the adsorption of aluminum foil stamping of the adhesive, the foil adhesion decreased, resulting in hot stamping or not.

- Q:Hot stamping materials

- The fifth layer is the adhesive layer, and the aluminized layer is glued to the substrate such as paper and the like. Aluminum foil is mainly to gold and silver, with gorgeous appearance, bright color, glittering, easy to use, suitable for printing on paper, plastic, leather, coating fabric, organic glass, plastic and other materials, is a kind of modern printing materials most commonly used.

- Q:What's the use of hot stamping paper?

- Anodized aluminum foil is mainly heated and pressurized way, the pattern or text transferred to the surface of the hot stamping material. To complete this process, the need for a hot stamping machine, with special characters or patterns of the template (such as zinc, copper foil, silicone version, etc.) is heated to the desired temperature, transfer required pressure and keep corresponding toggle between. Note that in the hot stamping of different materials, should choose the appropriate type of anodized aluminum, and choose the right temperature, pressure, stamping time, in order to achieve the desired effect of stamping.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

3003 Aluminium Coil And Aluminium Strip Household Aluminium Foil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords