3003 1060 Corrugated Aluminium Roofing Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specifications of 3003 1060 Corrugated Aluminium Roofing Sheet

name:corrugated aluminium sheet

alloy:1000,3000

thickness:0.4mm~1.5mm

width range: 1000mm-1500mm

2. Description of 3003 1060 Corrugated Aluminium Roofing Sheet

Aluminium Corrugated sheet are rippled metal sheets, primarily used at roofing, decking, and siding. Aluminum Corrugated sheet is tough, light weight, weather resistant and practical. We can produce aluminum corrugated roofing, siding, decking, and flooring for any application.

3. Package and shipping of 3003 1060 Corrugated Aluminium Roofing Sheet

standard export package or as per customer request

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

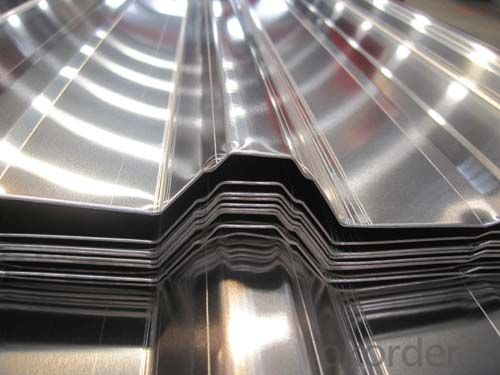

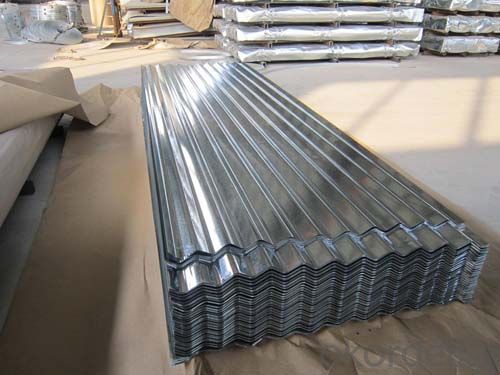

5. Image of 3003 1060 Corrugated Aluminium Roofing Sheet

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

8. Key Specifications/Special Features

1. Aluminum roofing sheets 2. 3003, h44. 3. Color coated as ral color chart. 4. Widely used as ware, garage roofing sheets. 3003, h44 aluminum roofing sheets can be color coated as ral color chart. It's the most widely used roofing materials in warehouse, garage for roofing sheets. We have many customers like in affrica,. During the entire production process of aluminium coating sheet from pre-treatment to finished product, we use international famous quality raw and auxiliary materials, for example aluminum sheets from the famous xinan aluminum industry and some other famous aluminum industry in china, pre-treatment made of ... With the famous germany henkel & chemtell from germany, above 70% pvdf from ppg co.,usa and the polyester coating from sweden becker industrial coating co. With the most advanced equipment and production technology, as well as top raw made of ... Brands, we produce high-quality and reliable colorful aluminium coating sheet. Theyve been widely used on the high-grade aluminum composite panel industry, now we take a lions market share and become one of the largest manufacturers in the face of the earth. Specification:. Coating type: pe (polyester resin) made of ... And pvdf (polyvinylidene fluoride) made of ... . Thickness: 0.2 ~ 1.2 mm,. Width: 800 ~ 1520 mm,. Annual production capacity: 8000 tons.

- Q:Are 101 aluminum sheets suitable for lightweight structural applications?

- 101 aluminum sheets are appropriate for lightweight structural applications. Aluminum is well-known for its lightweight characteristics, making it a popular option for structural applications that prioritize weight reduction. The 101 aluminum alloy is specifically engineered to provide high strength and excellent formability, making it an ideal selection for various structural components. These sheets can be utilized in industries such as aerospace, automotive, and construction, where the emphasis is on reducing weight while maintaining structural integrity. Furthermore, 101 aluminum sheets possess good corrosion resistance, rendering them suitable for outdoor applications or environments with elevated moisture levels. In conclusion, 101 aluminum sheets are a dependable choice for lightweight structural applications due to their strength, formability, and corrosion resistance properties.

- Q:how to separate the aluminum sheet in plastic?

- Put them into clean water if both of them won’t react with water, and aluminum sheet will sink into the bottle, then fish up them separately.

- Q:What are the different forming methods for aluminum sheets?

- There are several different forming methods that can be used to shape aluminum sheets. These methods include: 1. Roll Forming: This process involves passing the aluminum sheets through a series of rollers that gradually shape the material into the desired form. Roll forming is often used to create long, continuous shapes such as channels or rails. 2. Press Forming: Press forming uses hydraulic or mechanical presses to apply force to the aluminum sheet, creating the desired shape. This method is commonly used for forming complex shapes with tight tolerances. 3. Stretch Forming: In stretch forming, the aluminum sheet is clamped at its edges and then stretched over a die, causing the material to conform to the shape of the die. This method is often used to produce curved or contoured parts. 4. Deep Drawing: Deep drawing involves placing a blank of aluminum sheet into a die and then using a punch to force the material into the die cavity, creating a hollow shape. This method is commonly used to produce cylindrical or box-shaped parts. 5. Hydroforming: Hydroforming uses hydraulic pressure to shape the aluminum sheet against a die. This method is particularly useful for producing complex, intricate shapes with smooth surfaces. 6. Incremental Sheet Forming: In incremental sheet forming, a CNC machine moves a small tool over the surface of the aluminum sheet, gradually shaping it by applying localized pressure. This method is often used for prototyping or small-scale production. These forming methods offer different advantages and are suitable for different applications. The choice of method depends on factors such as the desired shape, complexity, and volume of production.

- Q:is aluminum foil spacer poisonous after heating?

- many baked food will use aluminum foil.

- Q:Can anyone tell me what to be careful of if you have aluminum wiring in your house. I was told that if the wall gets hot, I need to tighten the screws of the inside switch. Is this true and if I didn't, would it actually cause a fire in the wall. If this is true, how often does it loosen?

- There are several ways to take care of your problem. 1) Change all the wiring to copper. 2) Pigtail with copper wire and al/cu wirenuts to all new devices 3) Use copalum at all your boxes (this method is the best, besides replacing all your wiring to copper). Basically it cold welds the aluminum to the copper and makes a molecular bond. It's pretty expensive, and you'll have to look to find someone that actually knows how to do it, and has access to the crimping tool. Going around and tightening your devices won't hurt, but won't be fixing any longer term issues you may have with the aluminum wire. Keep in mind that if the original installation was done correctly, your circuits aren't overly tapped, and all the wires are on the appropriately sized breakers, then you may not have to worry much. Just run dedicated lines to any your new circuits. In other words, don't tap off these circuits. Hope this helps.

- Q:Can aluminum sheets be used for pharmaceutical lab equipment?

- Yes, aluminum sheets can be used for pharmaceutical lab equipment. Aluminum is a versatile material that offers various advantages for pharmaceutical applications. It is lightweight, corrosion-resistant, and has excellent thermal conductivity. These properties make aluminum an ideal choice for constructing lab equipment such as trays, shelves, and cabinets that are used for storage and transportation of pharmaceutical materials. Additionally, aluminum can be easily cleaned and sterilized, which is crucial for maintaining hygienic conditions in pharmaceutical laboratories. However, it is important to note that certain pharmaceutical processes may require specific materials that meet certain regulatory standards. Therefore, it is always advisable to consult with industry experts or regulatory bodies to ensure that the chosen aluminum sheets meet the necessary requirements for the intended use in pharmaceutical lab equipment.

- Q:Aluminum is put into copper chloride and how can you tell what happens to them visually?

- The aluminum metal appears to be turning into copper, but it is actually just removing the metallic copper from its compound state. The Aluminum is oxidized and loses e-, becoming Al 3+ and the copper ions are reduced (they accept those e-) to form solid copper precipitate. The aluminum ions and chloride ions remain in the solution. The reaction will only occur in water and occurs because the transfer of electrons from the aluminum to the copper results in a more stable system.

- Q:I'm trying to use as little aluminum as possible as it can be related to health problems, and I'm just trying to be a little more careful. I just bought the Emerilware pro-clad pot and pan set, and it's stainless steel but says Emerilware Pro-Clad is constructed with an aluminum core bonded between two layers of stainless steel ideal for... Therefore, I'm still cooking with aluminum. Is it safer since it's between 2 pieces of stainless steel? Does any stainless steel cookware not use aluminum? Thanks.

- First of all, there is no link between health problems and aluminum. Years ago, they thought there might be a link between alzheimer's and aluminum, but that has since been disproved. Secondly, stainless steel is a poor conductor of heat. But the stainless is a great, sturdy, non-reactive metal to use for cookware. So they add aluminum or copper to it's core to help it heat properly. Copper will cost you an arm and a leg, so all other cookware uses aluminum. If you had stainless cookware with no aluminum, it would take you an hour to boil water and your food would cook terribly unevenly. The outsides would burn before the inside cooked. So no, you won't find stainless without aluminum unless it's copper cored. But again, aluminum will do you no harm. You wrap your food in tin foil, which is aluminum. You eat food that has been sitting in aluminum cans on the shelf for god knows how long. And the anti-perspirant you use every morning? Check the ingrediants. Aluminum. Right on your lymph nodes. Stop worrying. Still worrying? aluminum is basically poreless. No aluminum will leach through. You are safe.

- Q:Are aluminum sheets suitable for automotive body panels?

- Yes, aluminum sheets are suitable for automotive body panels for several reasons. Firstly, aluminum is a lightweight material, which helps improve fuel efficiency and overall vehicle performance. This can result in better acceleration, handling, and braking. Additionally, the use of aluminum body panels can contribute to reducing the overall weight of the vehicle, which is particularly important for electric vehicles, as it can extend their range. Secondly, aluminum has excellent corrosion resistance properties. It naturally forms a protective oxide layer on its surface, which helps prevent rusting and deterioration caused by exposure to various weather conditions. This makes aluminum sheets highly durable and long-lasting, ensuring that automotive body panels maintain their structural integrity over time. Furthermore, aluminum is highly malleable and can be easily formed into complex shapes using various manufacturing techniques such as stamping, extrusion, and hydroforming. This allows for greater design flexibility, enabling automakers to create vehicles with sleek and aerodynamic body styles. Additionally, aluminum can be easily joined through welding or adhesive bonding, making it easier to assemble and repair automotive body panels. Moreover, aluminum is a sustainable material as it is highly recyclable. Recycling aluminum requires significantly less energy compared to primary production, resulting in reduced greenhouse gas emissions. This aligns with the growing emphasis on sustainability and environmental consciousness in the automotive industry. Overall, the use of aluminum sheets in automotive body panels offers numerous advantages such as improved fuel efficiency, corrosion resistance, design flexibility, and sustainability. These factors make aluminum a suitable and increasingly popular choice for automakers aiming to enhance the performance, durability, and environmental friendliness of their vehicles.

- Q:Are aluminum sheets suitable for automotive applications?

- Aluminum sheets are indeed suitable for automotive applications. Aluminum, being a lightweight material, presents several advantages for automotive use. To begin with, aluminum boasts exceptional resistance against corrosion, making it an excellent choice for exterior parts that are exposed to harsh environments. Moreover, aluminum offers a remarkable strength-to-weight ratio, ensuring high durability while keeping the overall weight of the vehicle at a minimum. Consequently, this results in enhanced fuel efficiency and superior performance. Furthermore, aluminum sheets are highly malleable, enabling manufacturers to fashion intricate shapes and designs for a variety of automotive components. Additionally, aluminum is recyclable, making it a sustainable option for the environment. All in all, the utilization of aluminum sheets in automotive applications provides numerous benefits, including weight reduction, improved fuel efficiency, resistance to corrosion, and flexibility in design.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

3003 1060 Corrugated Aluminium Roofing Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords