300 Copper Continous Extrusion Machine with High Capactity

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Copper Extrusion Machine for all series

- The History of the copper extrusion machine

The Conform Extrusion/Copper Extrusion Machine is a newly-developed [Metal Plastic Processing Technology] .

- The Application of the copper extrusion machine

To produce:

l Copper bus bar from copper extrusion machine

l Copper flat wire from copper extrusion machine

l Copper round wire from copper extrusion machine

l Shaped copper material under approximate any size… …

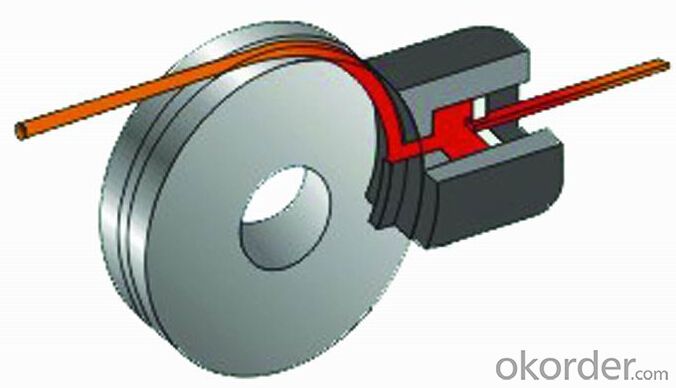

- The theory of the copper extrusion machine

Tooling and Steps of the conform theory:

[1] the continuously-rotating extrusion wheel,

[2] the frictional force between the wheel groove,

[3] continuous rod’s pulling,

[4] the plastic deformation happens inner the die chamber.

[5] And finally the output is extruded out.

For continuous cladding process, two aluminum feed-stocks are employed, and the chamber is fitted on the upper position of the extrusion wheel. The core wire or steel wire is fed in the tangential direction, and the aluminum feed-stocks are formed into the aluminum pipe through the chamber, then the aluminum pipe wraps around the core wire to be formed into the cladding or sheathing product.

The revolving extrusion wheel is driven by a motor, and it guides the feedstock to enter the wheel groove. The feedstock is dragged into the chamber by the friction between the wheel groove and feedstock. The friction generates high temperature and heavy pressure, under the high temperate and pressure, the metal is formed into the pipe or profile through a die.

Advantages of copper extrusion machine

1. Lower energy consumption

2. Better microstructure

The continuous extrusion method use oxygen free copper rod and has natural closed space during extruding and can easily produce oxygen free copper bar. It is impossible for the traditional process.

3. Higher material using ratio

The excess stock of traditional extrusion process and waste heads after drawing process cause low utilization ratio of material

4. Lower labor and processing cost

The traditional process needs more manpower and great worker's labor intensity,

Tech. parameters of production line | ||||

Type | SNLD350 | SNLD400 | SNLD500 | |

Nominal Diam. of extrusion wheel (mm) | 350 | 400 | 500 | |

Material type (Up-ward oxygen free copper rod) | Pure copper /brass copper | Pure copper /brass copper | Pure copper /brass copper | |

Max. product width (mm) | 80 | 170 | 240 | |

Max. sectional area (mm²) | 600 | 2000 | 3800 | |

Production capacity (kg/h) | 860 | 1300 | 2000 | |

- Q:Does anyone know the operating procedures for the cable 65+120 extruder?

- What are the operating specifications for the extruder?One is the equipment instructionTwo is the boot operation specificationsThree is safety instructions and so onThe equipment manufacturer will provide the above

- Q:extrusion machine prone to coke material, what is the cause? How to improve or solve?

- Is the place where the material is easy to burn rough? Add stabilizers and lubricants appropriately.

- Q:Extrusion machine operating procedures, specific points, thank you!

- 11 prohibit the use of hand to touch the dry test machine high-voltage appliances, electrical wiring or ground wire parts.No water on the 12 wire core.13, do not stop before the hand touch insulated wire core, wire connector and exposed parts; after high voltage breakdown, the wire core should first take discharge measures, and then repair.14 driving and parking should be directed by skilled workers to avoid misuse and risk.15, equipped with softening equipment, plastic machine, the operator can not arbitrarily move, adjust electrical and mechanical equipment; can not touch the wire, electric pulley, copper catheter parts.16 after the end of the drive, the power supply, water source and air source should be all closed, and the operation handle will be replaced in place, and the records of the shift shift will be kept in good order.

- Q:What is the adjustment method of China's extrusion machine die?

- (2) run mode: plastic glue on the plasticizing after adjustment for mold screw, die according to how much glue circle, ran glue, side adjustment, adjustment should be loose thin screws, tighten the screws run glue thick; at the same time sampling check plastic thickness is eccentric, until evenly so far, then tighten the screw die respectively.

- Q:Where is the Huangyan extruder machine?

- You want to see what type of mold processing, but Masino comprehensive, injection mold, blow mold, mold and so on can be developed.

- Q:Wire and cable extrusion machine temperature exceeds the process documentation, what are the reasons?

- As far as actual production is concerned, it is necessary to go beyond the regulations to produce normally

- Q:Why will the extruder frequency shift stop?

- Because the frequency converter is out of order, you can look at the fault record parameters of the inverter.

- Q:Taper twin screw extrusion machining of plastic masterbatch? What ancillary equipment do you need?

- because itself is not suitable for the design of double cone, adjustment of the formula is the key.

- Q:What are the components of an extruder?

- The driving system of an extruder is to drive the screw, providing the torque and speed required by the screw in the extrusion process, usually consisting of an electric motor, a reducer, and a bearing.3. heating and cooling device for extruderHeating and cooling are necessary conditions for the process of making a plastic extruder. It includes two aspects:(1) now host extruder is usually divided into electric heating, resistance heating and induction heating, heating installed in the fuselage, neck, head of each part. The heating device heats the plastic in the outer barrel to increase the temperature required for the process operation.(2) the cooling device is designed to ensure that the plastic is in the temperature range required by the process. Specifically, to eliminate the excess heat generated by the shear friction of the screw rotation, in order to avoid the temperature is too high, so that plastic decomposition, coke burning or stereotypes difficult. Cylinder cooling water cooling and air cooling is divided into two kinds, small and medium sized extrusion machine adopts air cooling is more appropriate, large use more water or two kinds of combined cooling; cooling water cooling screw mainly adopts the center, the purpose is to increase the solids conveying rate, stable glue volume, and improve product quality; but in the cooling hopper one is, in order to strengthen transport of solid material, prevent warming plastic sticky jam outlet, two is to ensure the normal work of the transmission part.

- Q:Why? What is the raw material of plastics? What is the process flow of the process?.

- It must be injection, you see that hole, that button, can not squeeze out.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

300 Copper Continous Extrusion Machine with High Capactity

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products