3.0mm White Food Grade Felt Surface PVC Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

3.0mm White Food Grade Felt Surface PVC Conveyor Belt

Conveyor Belt Description:

Color White

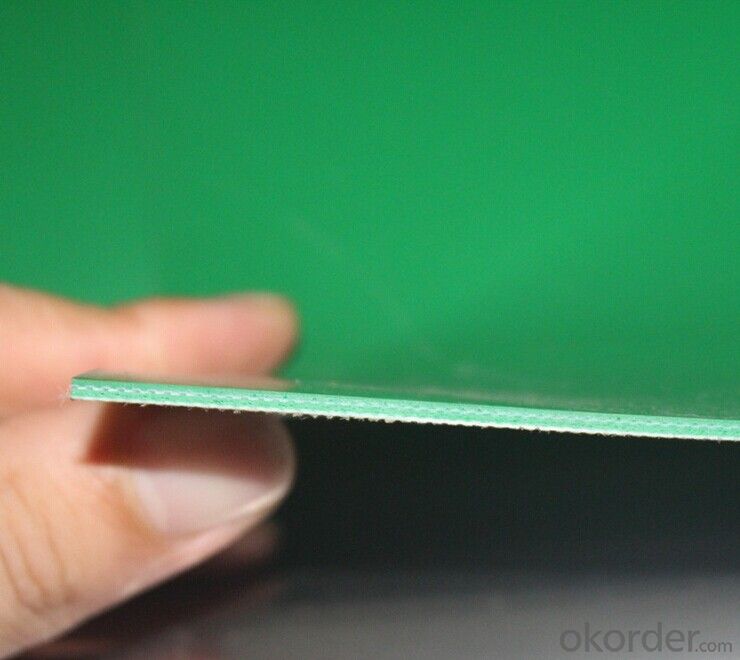

Fiber layers 2 plies

Fiber class Lateral stability polyester fabric

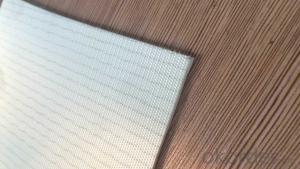

Surface material Wool felt

Surface pattern --

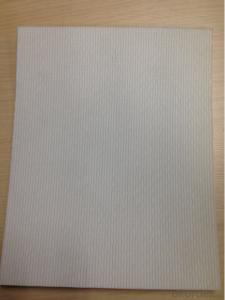

Bottom material Polyester fabric

Total thickness 3.0mm

Surface coated thickness 1.0mm

Weight 2.9kg/sqm

Maximum width 2200mm

Elongation 1% force 10N/mm

Hardness shoreA --

Working temperature -10~+80℃

Minimum pulley diameter 80mm

Application Pallet or roller conveyor.Food bakery industry.

Conveyor Belt Feature

1)Low stretch;

2)Low maintenance;

3.Anti-static;

4)Flexible;

5.Lightweight;

6)Impervious to moisture,acids,oils,gases,sunlight;

7)Excellent fastener holding;

8)Excellent resistance to tearing,peeling and impact;

9)Endless belt splicing;

10)Special wear resistant edge design;

Conveyor Belt Applications

Food industry

Conveyor Belt Photos

FAQ

Q: Can you do OEM?

A: Yes, we can do OEM products based on your requirements.It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1)All raw material we used are environmental-friendly;

2)Skilful workers care every details in handling the producing and packing processes;

3)Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance payment before shipment.

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC conveyor belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q:What if the plastic is broken?

- The adhesive is bonded between the two bonding surfaces and is coated with suitable adhesive to form a layer of glue. The two parts are bonded together by the action of the adhesive layer. It is the only adhesive method for thermosetting plastics

- Q:Can olive nets be used in combination with tree training methods?

- Yes, olive nets can be used in combination with tree training methods. Olive nets are commonly used to protect olive trees from pests, birds, and excessive sunlight. They can be installed around the trees while following specific tree training methods such as espalier, central leader, or open center pruning. By using olive nets along with proper tree training techniques, olive growers can promote healthy tree growth and protect their crop effectively.

- Q:How does an olive net affect the time required for harvesting?

- An olive net significantly reduces the time required for harvesting by catching the olives as they fall from the tree, preventing them from scattering on the ground and making it easier to collect them efficiently.

- Q:How does an olive net affect the overall fruit size in the olive grove?

- An olive net can have a positive effect on the overall fruit size in an olive grove. By placing nets over the trees, it provides protection from external factors such as wind, pests, and extreme temperatures. This protection allows the olives to grow undisturbed and reach their full potential in size and quality. Additionally, the netting also prevents premature dropping of olives, ensuring a higher yield and larger fruit size in the olive grove.

- Q:Are olive nets customizable?

- Yes, olive nets can be customized to fit specific dimensions and requirements.

- Q:Can olive nets be used for olive tree shade management?

- Yes, olive nets can be used for olive tree shade management. These nets are specifically designed to provide shade to the olive trees, helping to regulate the temperature, reduce evaporation, and protect the fruit from sunburn. Additionally, olive nets also serve as a barrier to prevent birds from damaging the crop. Overall, olive nets are a practical solution for shade management in olive tree cultivation.

- Q:Are olive nets resistant to weather conditions?

- Yes, olive nets are designed to be resistant to various weather conditions. They are made from durable materials that can withstand rain, wind, and sunlight, ensuring long-lasting protection for olive crops.

- Q:Can olive nets be used for olive trees in coastal areas?

- Yes, olive nets can be used for olive trees in coastal areas. Olive nets are specially designed to protect the olives from birds and other pests during the fruiting season. They can provide additional benefits in coastal areas by protecting the olives from strong winds and salt spray. However, it is important to ensure that the nets are securely anchored to withstand coastal conditions, and regular maintenance may be required due to the potential effects of salt and moisture.

- Q:How to make plastic products soft?

- This is actually very simple, you can put him in the heating on a small would like or use hot water but this is useful if you want to be a short time long time it is very difficult because the weather is cold now, so it is hard to soft the other day will be better if you don't is not how love feeling if I still advise you to buy a good very soft

- Q:Do olive nets require any special maintenance?

- Yes, olive nets do require special maintenance. They need to be regularly inspected for any damages or tears, and any repairs should be made promptly to ensure their effectiveness. Additionally, olive nets should be cleaned and stored properly after each use to prolong their lifespan.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

3.0mm White Food Grade Felt Surface PVC Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords