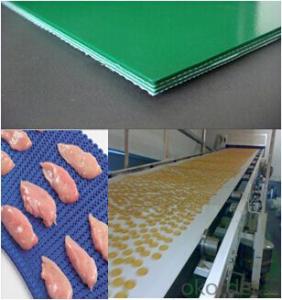

3.0mm PVC Green Conveyor Belt for Light Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

3.0mm PVC Green Conveyor Belt for Light Industry

Specifications

Anti-static and tearing resistant

Abrasion and oil/heat/fire resistant

Working temperature ranges from -10 to 80Deg.C

With advanced coating machine and other excellent facilities, we are professionally producing PVC&PU light conveyor belts, which are extremely suitable for light industry such as beer industry, paper making industry, food industry, textile industry etc.

Product Feature

*Anti-static and non-conductive

*Food quality types to FDA standards

*Resistance to abrasion, oils, fats and chemicals

*Surfaces with low, medium or high coefficient of friction

*High transverse rigidity and dimensional stability

* Low noise

* Working temperature ranges from -10 to 80Deg.C

Product pictures:

- Q:The action of various ingredients in rubber formula

- Curing system: vulcanizing agent, accelerator, active agent, anti coke agent,

- Q:How are rubber wires processed?

- [summary] the main raw material is rubber, rubber products with various agents, as well as the fiber and metal skeleton material, the basic production process of rubber products including plastication, mixing, calendering, extrusion, molding, curing 6 basic processes.The processing process of rubber is mainly to solve the process of plastic and elastic contradictions, through various means of processing, the elastic rubber has become the plastic rubber, adding various in the preparation of semi-finished products, and then through the vulcanization is has semi-finished plastic and rubber products into high elasticity and good mechanical performance the.

- Q:Is vulcanized sole good or rubber sole is good?

- Rubber base, vulcanized bottom are basically the same, rubber vulcanization is only the process of shoe-making, rubber is the bottom of the way vulcanized and uppers together, it is more difficult to open

- Q:What about the Poisson's ratio and modulus of elasticity of three yuan ethylene propylene rubber (EPDM)?

- The Poisson's ratio and modulus of elasticity of three yuan ethylene propylene rubber (EPDM) are approximately:Rubber elastic modulus 0.0078GPa, Poisson's ratio 0.47.

- Q:Is work in rubber products harmful to health?

- The raw material of rubber products is rubber compound, and the rubber compound has five components:Main rubber. Rubber main glue is not toxic.Reinforcing agent. Most of the reinforcing agents are not toxic.Softener. Is the most emollient mineral oils, high temperature volatile hazardous substances.Antioxidant. Some poisonous.Vulcanizing agent. The vulcanizing agent is generally sulfur, sulfur will release a high temperature sulfur dioxide, sulfur dioxide, sulfur dioxide, hydrogen sulfide gas three.

- Q:Are there formaldehyde in rubber products, too?

- 1, stimulation: mainly affect performance of formaldehyde for the stimulation of the skin and mucous membrane, formaldehyde is a protoplasmic poison, can bind with protein, when high concentrations of inhaled respiratory severe irritation and edema, eye irritation, headache.2, sensitization: skin direct contact with formaldehyde can cause allergic dermatitis, pigmentation and necrosis, inhalation of high concentrations of formaldehyde can cause bronchial asthma.3. Mutagenicity: high concentration formaldehyde is a genotoxic substance. Laboratory animals can cause nasopharyngeal tumors at high concentrations in the laboratory.

- Q:Process for producing rubber products

- There are many kinds of rubber products, but the production process is basically the same. The basic process of rubber products in general solid rubber - rubber as raw materials including: plastication, mixing, calendering, extrusion, molding, curing 6 basic processes. Of course, raw materials preparation, finishing, inspection, packaging and other basic processes are indispensable. The processing of rubber mainly deals with the contradictory process of plasticity and elasticity. Through a variety of techniques, the elastic rubber plastic rubber has become the addition of various additives made of semi-finished products, and then through the vulcanization has semi-finished plastic and rubber products into high elasticity and good mechanical performance.

- Q:How to remove the rubber front?

- Conversely, the product is small, large in quantity, or where it is hard to repair, so you can consider machine trimming.

- Q:What does rubber mean?

- High elastic polymer compound. It is divided into two kinds: natural rubber and synthetic rubber. Natural rubber is made from rubber, tree, rubber, grass and other plants. The synthetic rubber is obtained by polymerization of various monomers.

- Q:Is the odour emitted by industrial rubber poisonous?

- Rubber production process including plastic, mixing, rolling or extrusion, molding and vulcanizing and other basic processes, each process for the products have different requirements, respectively, with a number of auxiliary operations.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

3.0mm PVC Green Conveyor Belt for Light Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords