295W CNBM Solar Monocrystalline Series V (295W—305W)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 watt

- Supply Capability:

- 500000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

CNBM Solar Monocrystalline Series V (280W—290W)

Characteristics

| Max Power Voltage Vmp(V) | 34.7 | 35 | 35.5 | |

| Max Power Current Imp(A) | 8.51 | 8.58 | 8.65 | |

| Open Circuit Voltage Voc(V) | 41 | 41.3 | 41.7 | |

| Short Circuit Current Isc(A) | 9.25 | 9.3 | 9.35 | |

| Max Power Pm(W) | 295 | 300 | 305 | |

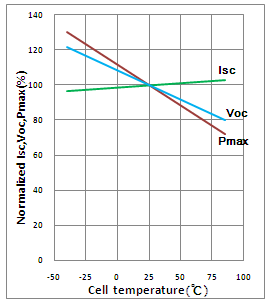

Temperature Coefficient of Cells

| NOCT | 45℃±2℃ | |||

| Temperature Coefficients of Isc (%/℃) | - 0.039 | |||

| Temperature Coefficients of Voc (%/℃) | –0.31 | |||

| Temperature Coefficients of Pmp (%/℃) | –0.42 | |||

Mechanical Data

| Dimension | 1954 x 982 x 45 mm | |||

| Weight | 27.5kg | |||

| No. of Cells and Connections | 72 (6 x 12) | |||

| Tolerance | –0.42 | |||

| Cell Monocrystalline Cell | 156 x 156 mm | |||

| Packing | 528 Pcs/40ft(H) Container | |||

Limits

| Operating Temperature | –40 °C to +85°C | |||

| Storage Temperature | –40 °C to +85°C | |||

| Max System Voltage | 1000VDC(IEC) / 600VDC(UL) | |||

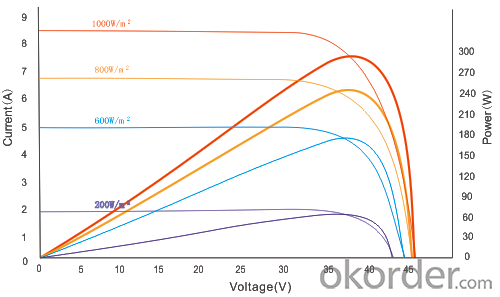

IV Curve

Image

Guarantees

Products Guarantee 12 yrs free from defects in materials and workmanship

Performance Guarantee No less than 90% within 10yrs and no less than 80% within 25yrs

Certificates TUV (IEC61215&IEC61730), VDE(IEC61215&IEC61730), UL, CE

FAQ

1. Q: Do you have your own factory?

A: Yes, we have. Our factory located in Jiangsu province.

2. Q: How can I visit your factory?

A: Before you take off from your country, please let us know. We will show you the way, or arrange time to pick you up if possible.

3. Q: Do you provide free sample?

A: Usually we do not offer free sample

4. Q: Could you print our company LOGO on the nameplate and package?

A: Yes, we can do that.

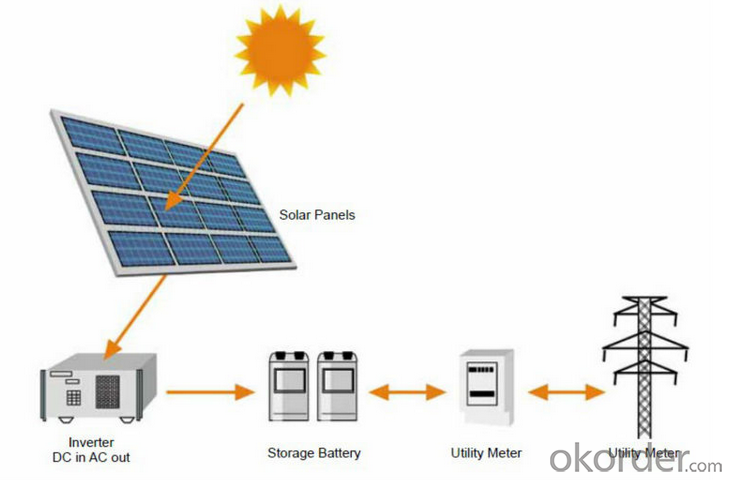

- Q:Can solar panels be used to power a construction site?

- Yes, solar panels can be used to power a construction site. They can provide a sustainable and renewable source of energy, reducing the need for traditional fuel-based generators and minimizing carbon emissions. Solar panels can be installed on rooftops or on portable structures, providing electricity to power tools, lighting, and other equipment required on a construction site. Additionally, excess energy generated by solar panels can be stored in batteries for use during non-sunlight hours, ensuring continuous power supply.

- Q:when we say a solar panel has 20% efficiency, do we mean that it converts 20% of sunlight reaching it into electricity or that it converts 20% of visible light(which is only 7% of sunlight) into electricity?

- That portion of the sun's light to which it responds, of which it converts 20% to electricity.

- Q:Can anyone give me some info on how to figure how many panels needed for a 0 volt 2 amp pool motor. Thanks/ Run 5 hours a day

- I don't think heating a 70,000 gallon pool with solar panels is practical. My husband has designed and built our solar hot water system. It works quite well. We live in Arizona. There's no way we could heat that much water using sun energy. You have to heat the water and compete with the outside air.

- Q:Can solar panels be installed on a sloped roof?

- Yes, solar panels can be installed on a sloped roof. In fact, many residential and commercial buildings with sloped roofs have successfully installed solar panels to generate renewable energy. The angle of the slope can affect the efficiency of the panels, but with proper installation and positioning, solar panels can still effectively harness sunlight and produce electricity.

- Q:Are solar panels suitable for commercial use?

- Yes, solar panels are highly suitable for commercial use. They offer numerous benefits such as reducing energy costs, providing a stable and reliable source of electricity, and promoting sustainable practices. Additionally, many governments and organizations offer incentives and tax benefits for businesses that implement solar energy systems. Overall, solar panels are a practical and cost-effective solution for commercial establishments aiming to reduce their environmental footprint and save on energy expenses.

- Q:Dose a solar panel need the entire range or spectrum of sunlight to produce power?

- It's a huge field of study, very important to solar cell development. People are trying to optimize spectral response for sunlight, even for sunlight in specific places. Google solar cell spectral response for many many websites. Most of them are specific to one experiment.

- Q:Can solar panels be installed on sloped roofs?

- Yes, solar panels can be installed on sloped roofs. In fact, sloped roofs are one of the most common types of roofs where solar panels are installed. The angle of the roof can be adjusted to optimize the positioning of the solar panels and increase their efficiency.

- Q:Can solar panels be used in conjunction with a backup generator?

- Yes, solar panels can be used in conjunction with a backup generator. This setup is known as a hybrid solar power system and it allows for continuous power supply even during periods of low sunlight or when the solar panels are not generating enough electricity.

- Q:Can solar panels be used in conjunction with wind turbines?

- Yes, solar panels can be used in conjunction with wind turbines. This combination of renewable energy sources is known as a hybrid system and can provide a more reliable and consistent electricity generation. By utilizing both solar and wind power, the system can generate electricity during both day and night, as well as during varying weather conditions. This integration allows for a more efficient and sustainable energy production.

- Q:Can solar panels be installed on a carport or parking lot?

- Yes, solar panels can be installed on a carport or parking lot. This is known as solar carport or solar parking lot systems. They provide shade for parked vehicles while generating clean and renewable energy.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

295W CNBM Solar Monocrystalline Series V (295W—305W)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 watt

- Supply Capability:

- 500000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords