288 Cells OEM Plastic Nursery Tray&Lids Plastic Nursery Seed Plug Trays for Propagation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

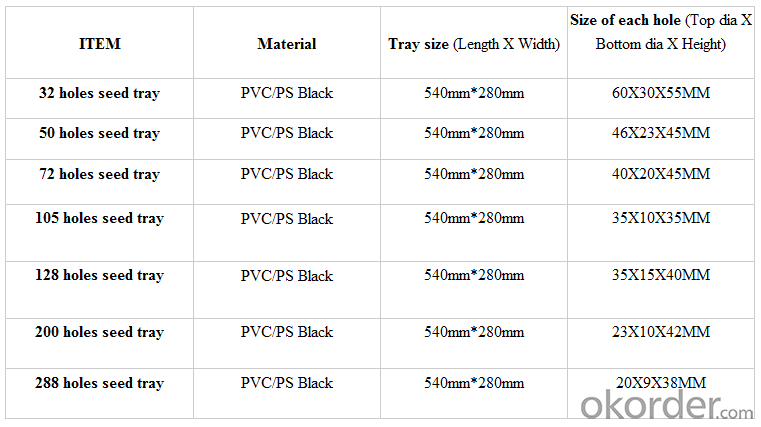

Specification of Plug Trays HIPS Made Plastic Plug Tray for Greenhouse (Growing and Seedling):

Features of Plug Trays HIPS Made Plastic Plug Tray for Greenhouse (Growing and Seedling):

· Material: HIPS

· Thickness: 0.5mm-1.5mm, Standard:1mm

· Weight: 80g(±5)g-230g(±5)g, Standard weight:155g(±5)g

· Size: length:490mm-540mm, width:190mm-345mm,depth:25mm-150mm

· Standard:540mmX280mm

· Cell count: 18-512

· Package: In Carton

· Warrenty: 8-10 times

Packaging & Delivery

Packing Detail: export standard carton or large bags

Delivery time: 4 million per momth after receipt of deposit

Advantage:

Waterproof, UV-resistant, extrusion-resistant

Easy carry for young seeding plant and grow

Service:

1. Quick, efficient and professional response within 24 hours, 14 hours online services

2. 10 years manufacturing and exporting experience in agriculture field.

3. Technical support and solution by chief engineer.

4. Strict quality control system & team, high reputation in the market.

5. Full range of irrigation products for choice

6. OEM/ODM services

7. Accept sample order before Mass Order

Picture of Plug Trays HIPS Made Plastic Plug Tray for Greenhouse (Growing and Seedling):

FAQ of Plug Trays HIPS Made Plastic Plug Tray for Greenhouse (Growing and Seedling):

Q: 1.How long is the production time?

A: Usually one to two weeks.

Q: 2.How is the seed tray being packaged?

A: They can be packaged in carton or pallets. Carton size is 1375px*725px*1250px.

Q:3.How many times can the seed tray be used?

A: Under the same environment, it is decided by the thickness. Usually 0.6mm thickness can be used for 1 or 2 times.

1.0 thickness can be used for 3-4 times. 1.5 thickness can be used for 8-10 times.

- Q:What are some ground cover options for areas with high foot traffic and shade?

- Some ground cover options for areas with high foot traffic and shade include creeping thyme, ajuga, moss, and mondo grass.

- Q:How does plastic windbreak netting help in protecting crops from wind damage?

- Plastic windbreak netting acts as a barrier against strong winds, reducing the impact on crops by creating a sheltered environment. It helps in preventing wind damage, such as broken stems, uprooting, or loss of yield, by reducing the force and speed of the wind that reaches the crops.

- Q:How do you establish ground cover plants in existing landscapes?

- To establish ground cover plants in existing landscapes, it is important to follow these steps: 1. Select the right ground cover plants: Choose plants that are suitable for the specific site conditions, such as sun exposure, soil type, and moisture levels. Consider factors like height, spread, and growth habit to ensure the plants will provide effective ground cover. 2. Prepare the planting area: Clear the area of any weeds, grass, or debris that may compete with the ground cover plants. Loosen the soil with a garden fork or tiller to improve drainage and root penetration. 3. Amend the soil if necessary: Test the soil pH and nutrient levels and make any necessary adjustments to ensure optimal growing conditions for the ground cover plants. Add organic matter like compost or aged manure to improve soil structure and fertility. 4. Plant the ground cover: Dig holes or trenches to accommodate the roots of the ground cover plants. Space them according to their recommended spacing requirements, ensuring they have enough room to spread and fill in the desired area. Gently backfill the holes with soil, firming it around the roots to eliminate air pockets. 5. Mulch the area: Apply a layer of organic mulch, such as wood chips or straw, around the newly planted ground cover. Mulch helps retain moisture, suppress weeds, and regulate soil temperature, promoting healthy growth. 6. Water and maintain: Water the ground cover plants thoroughly after planting and continue to provide regular irrigation until they are established. Monitor soil moisture levels and adjust watering accordingly. Remove any weeds that may emerge, and apply fertilizer or compost as needed to support plant growth. 7. Regularly monitor and maintain: Check the ground cover plants regularly for any signs of pests, diseases, or nutrient deficiencies. Prune or trim them as necessary to maintain their desired shape and prevent overcrowding. Regularly monitor and adjust irrigation to prevent over or under-watering. By following these steps, you can successfully establish ground cover plants in existing landscapes, creating an attractive and low-maintenance ground cover that adds beauty and functionality to the area.

- Q:Are nursery trays suitable for growing bamboo?

- Nursery trays can be suitable for growing bamboo, especially when the trays are large enough to accommodate the rapid growth and spreading nature of bamboo plants. However, it is important to ensure that the trays provide adequate drainage and enough space for the roots to grow. Additionally, bamboo should be transplanted into larger containers or directly into the ground once it outgrows the nursery trays to ensure proper development.

- Q:In what year did Plastic Bags become a severe problem to the environment?

- why do you think they're a problem? They're convenient, light weight, clean, and strong. 100 of them take up less space in a landfill than a milk carton/jug. They are NOT the problem in the oceans. The problem there is plastic fishnets that have been lost by fishing boats. The nets ARE a problem, since they float and continue to catch and trap anything that goes into them. Testing has found that reusuable environmentally friendly cloth bags, used as replacements for plastic bags, soon build up high levels of bacteria as they are reused, so they need to be washed frequently which requires lots of water and detergent. In addition, at a cost of up to $5 each, buying and storing enough of them at home to handle a single trip to the grocery store can get prohibitively expensive for poor families who may use up to 20 plastic bags each trip to market to haul their groceries home. As for a year that plastic bags became a problem....it was the year immediately after plastic was touted as the salvation of the trees chopped down to create paper bags for grocery stores. Never let an environmentalist tell you what to switch to. It'll never be good enough. Just like all the environmental lawsuits now showing up in courts to stop clean energy projects (dams, windmills, solar arrays, geothermal, etc). All they want is for everyone to die and leave the planet to the frickin animals, because surely everyone can see that humans are a blight on the planet and should never have evolved.

- Q:How many cells are typically in a nursery tray?

- The number of cells in a nursery tray typically varies, but a common standard is 72 cells per tray.

- Q:What are some common types of ground cover plants?

- Some common types of ground cover plants include creeping thyme, vinca minor, ajuga, sedum, pachysandra, and mondo grass.

- Q:What are the advantages of using plastic pruning tools for plant maintenance?

- Plastic pruning tools offer several advantages for plant maintenance. Firstly, they are lightweight and easy to handle, reducing the strain on the user's hands and arms during prolonged pruning sessions. Additionally, plastic tools are typically less expensive than their metal counterparts, making them a more affordable option for gardeners. Plastic pruning tools are also less likely to rust or corrode, prolonging their lifespan and ensuring consistent performance. Moreover, plastic tools are safe to use on delicate plants as they are less likely to cause damage or leave visible scars. Lastly, plastic tools are non-conductive, reducing the risk of electrical shock when pruning near power lines or electrical equipment. Overall, plastic pruning tools provide convenience, affordability, durability, safety, and versatility, making them a practical choice for plant maintenance.

- Q:Can agricultural plastic products be used for plant propagation?

- Yes, agricultural plastic products can be used for plant propagation. Agricultural plastic products such as pots, trays, and containers are commonly used in nurseries and greenhouse settings for starting and propagating plants. These products provide a controlled environment for seed germination and root development, offering protection and support to young plants. The plastic material also helps retain moisture and regulate temperature, enhancing the success of plant propagation.

- Q:How to choose tractor tires correctly

- The tread is raised with higher cross-country tread pattern, which is usually "man" or "eight". The pattern can increase the adhesion between the rubber wheel and the soil, reduce skidding, and have a certain anti skidding ability

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

288 Cells OEM Plastic Nursery Tray&Lids Plastic Nursery Seed Plug Trays for Propagation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords