285W CNBM Solar Polycrystalline Series III (280W—295W)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 watt

- Supply Capability:

- 500000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

CNBM Solar Polycrystalline Series III (280W—295W)

Characteristics

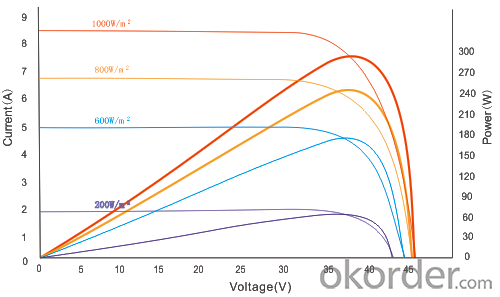

Max Power Voltage Vmp(V) | 36.6 | 36.9 | 37.2 | 37.5 | ||

Max Power Current Imp(A) | 7.66 | 7.73 | 7.8 | 7.87 | ||

Open Circuit Voltage Voc(V) | 44.2 | 44.6 | 45.1 | 45.4 | ||

Short Circuit Current Isc(A) | 8.26 | 8.32 | 8.41 | 8 | ||

Max Power Pm(W) | 280 | 285 | 290 | 295 | ||

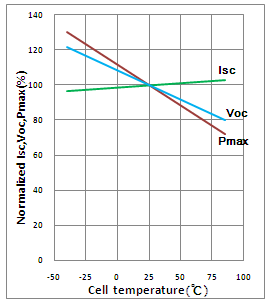

Temperature Coefficient of Cells

NOCT | 45℃±2℃ | |

Temperature Coefficients of Isc (%/℃) | - 0.0492 | |

Temperature Coefficients of Voc (%/℃) | – 0.3374 | |

Temperature Coefficients of Pmp (%/℃) | –0.4677 | |

Mechanical Data

Dimension | 1638 x 982 x 40 mm | |

Weight | 19.5kg | |

No. of Cells and Connections | 60 (6 x 10) | |

Tolerance | 0~+5W | |

Cell Monocrystalline Cell | 156 x 156 mm | |

Packing | 700 Pcs/40ft(H) Container | |

Limits

Operating Temperature | –40 °C to +85°C | |

Storage Temperature | –40 °C to +85°C | |

Max System Voltage | 1000VDC(IEC) / 600VDC(UL) | |

IV Curve

Image

Guarantees

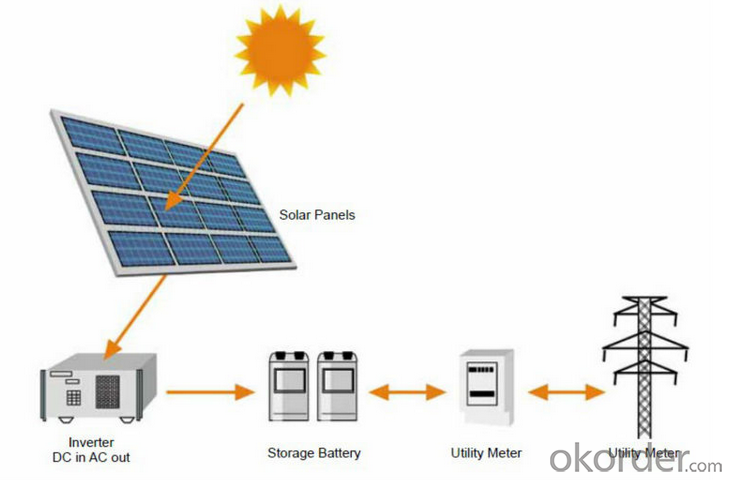

Products Guarantee 12 yrs free from defects in materials and workmanship

Performance Guarantee No less than 90% within 10yrs and no less than 80% within 25yrs

Certificates TUV (IEC61215&IEC61730), VDE(IEC61215&IEC61730), UL, CE

FAQ

1. Q: Do you have your own factory?

A: Yes, we have. Our factory located in Jiangsu province.

2. Q: How can I visit your factory?

A: Before you take off from your country, please let us know. We will show you the way, or arrange time to pick you up if possible.

3. Q: Do you provide free sample?

A: Usually we do not offer free sample

4. Q: Could you print our company LOGO on the nameplate and package?

A: Yes, we can do that.

- Q:How much does 000 square feet of solar panels cost? This is for a pool with dimensions 75ft by 25ft? How much will it cost including installation fee and the water heater?

- Are you asking about solar water heaters or solar electric panels?

- Q:I have a 20 watt solar panel that I want to set up. I need to connect it to the solar controller but do not know what cable to use. I plan on adding more solar panels down the line. What would be the best cable to use?

- on the controller, it writes which would be related with image voltaic panel which would be related with battery which would be related with load all of it write on the image voltaic controller. only see the controller

- Q:How do solar panels affect the aesthetics of a roof?

- Solar panels can have both positive and negative effects on the aesthetics of a roof. On one hand, they can enhance the visual appeal by giving the roof a modern and eco-friendly look. On the other hand, some people may find the appearance of solar panels less attractive or disruptive to the overall design of their roof. Ultimately, the impact on aesthetics largely depends on personal preferences and the design integration of the solar panels into the roof.

- Q:I know that if I put solar panels in my home I will get 30% back from the govt. Does that mean if I pay 2K I will get back around a 3K check? Or will my income play a roll where I may not get back as much?

- Not a good answer: CNBC had a news bit, that it can take 0 to 20 years for you to break even in energy costs after installing solar panels. Please don't buy them just for the tax deduction. See if you can google a calculator for this - do research. I have a brother in law that buys anything under the sun just because he gets a tax deduction. I'm sure you're not like that though. Run the numbers of what you will save vs the 2K you will spend You may never break even

- Q:How do solar panels affect the value of a home?

- Solar panels can have a positive impact on the value of a home. They are considered a valuable asset as they reduce energy costs and provide potential financial savings for homeowners. Solar panels also contribute to a greener and more sustainable lifestyle, which is increasingly valued by homebuyers. Additionally, homes with solar panels are often seen as more attractive and can stand out in a competitive real estate market, potentially increasing the overall value of the property.

- Q:okay so im lookin 4 an article which explains how practical, wokable, feasible solar panels are. only positive points please :) give me the link. PLZ HELP!!!!

- Solar Panels are practical because they provide electricity to your home directly avoiding the rates paid to the utility. They are pay themselves off in 5 years or less and supply an income stream in NJ for 5 years!

- Q:Can solar panels be used in multi-story buildings?

- Yes, solar panels can be used in multi-story buildings. They can be installed on the roof of the building or on vertical surfaces such as walls or balconies. The availability of space and the structural integrity of the building are important factors to consider when installing solar panels in multi-story buildings.

- Q:HIToday i was using my BB gun and shot my dads solar panel. I want to fix it for him because he spent a lot of time trying to get the solar panels. All i broke was the glass on the front, what is the glass and where can i buy new glass for it?

- Note: he didnt buy them, we found them at a property that we bought

- Q:Can solar panels be used in areas with high levels of pollution from industrial emissions?

- Yes, solar panels can still be used in areas with high levels of pollution from industrial emissions. While pollution can potentially reduce the efficiency of solar panels by blocking sunlight, advancements in technology and design have made solar panels more resilient. Additionally, regular maintenance and cleaning can help mitigate the impact of pollution on solar panels, ensuring they continue to generate electricity effectively.

- Q:Can solar panels be used in areas with high levels of pollution from industrial activities?

- Yes, solar panels can be used in areas with high levels of pollution from industrial activities. While pollution can have some impact on the efficiency of solar panels, they are still able to generate electricity even in polluted areas. Regular cleaning and maintenance of the panels may be required to ensure optimal performance. Additionally, installing solar panels in such areas can help offset some of the carbon emissions from industrial activities, contributing to a cleaner and more sustainable energy future.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

285W CNBM Solar Polycrystalline Series III (280W—295W)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 watt

- Supply Capability:

- 500000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords