254SMO stainless steel forgings/round bar/rod/pipe fittings

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 260000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Stainless steel bars,profiles,beams

Product Information:

(Physical Properties)

Density | 8.24g/cm3 |

Fusion Point | 1320-1390°C |

Standard:ASTM A182 | |

Mechanical Property

Alloy and state | Tensile Strength | Yield Strength | Elongation | Hardness |

RM N/MM2 | RP0.2N/MM2 | A5% | HB | |

Thin plate/strips | >=690 | >=310 | ó=35 | <=223< span=""> |

Sheet | >=655 | >=310 | ó=35 | <=223< span=""> |

254SMO Application field:

1.Petroleum, petrochemical equipment, such as the petrochemical equipment in the corrugated pipe

2. Pulp bleaching equipment, such as pulp digester, bleaching equipment, filter scrubber for bucket cylinder and pressure roller, etc..

3. Power plant flue gas desulfurization device, the main use of the site: absorption tower tower body, flue, block door, inside, spray system, etc..

4.Marine systems or sea water treatment, such as the power plant in the use of seawater cooling of thin walled condensate pipeline, seawater desalination processing equipment, even in the sea may not flow equipment can also be used.

5. Desalination industry, such as salt or desalination equipment

6. Heat exchangers, especially in the working environment of chlorine ion exchanger.

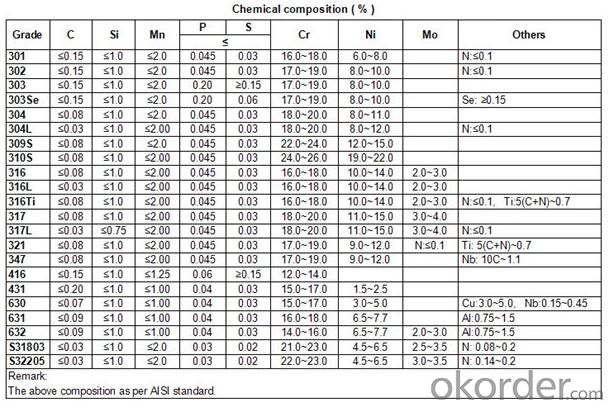

| 200 series: 201, 202 | |

| 300 series: 303, 304, 304L,321, 310S, 316, 316L | |

| 400 series: 410, 420, 430 | |

| Standard | AISI, ASTM, DIN, GB, JIS, SUS |

| Diameter | 2mm-300mm |

| Length | 1 meters to 9 meters or random |

| Surface | bright, black |

| Treatment | Hot rolled, cold drawn, Annealed, Grinding |

| Packing | Standard sea-worthy package or as required |

| Trade Terms | EXW, FOB, CFR, CIF |

| MOQ | 200 KGs Stainless Steel Round Bar |

| Payment | 30% deposit in advance, balance against copy of BL or irrevocable L/C at sight |

| Delivery | Usually 15-20 days upon receipt of deposit for 1 FCL |

Product Size Detail:

| Main operation | Main steel grade | Available size(mm) | Monthly capacity(mt) | Length(mm) | ||

| OEM | Stainless steel | 40~500 | 1500 | 4000~8000 | ||

| Hot | 303 303Cu 304/L 310S 316/L 321 416 420 | 12 ~200 | 3000 | 4000~7000 | ||

| 17-4PH WLA510 | ||||||

| ST Bar | 321 304/L 316/L 310S 17-4PH WLA510 | 19~110 | 2000 | 4000~7000 | ||

CD Bar | Round bar | 303 303CU 304/L 316/L 416 420 17-4PH WLA510 | 4.76~100 | 500 | 2500~6500 | |

| Square bar | 303 303CU 304/L 316/L 416 17-4PH WLA510 | 4.76~75 | 180 | 2500~6500 | ||

| Hex bar | 303 303CU 304/L 316/L 416 17-4PH WLA510 | 4.76~75 | 180 | 2500~6500 | ||

| CG Bar | 303 303CU 304/L 316/L 416 420 17-4PH WLA510 | 4.76~100 | 500 | 2500~6500 | ||

Specificate:

Our Advantages

• All products are made of high-quality imported raw materials.

• Our products are certified by ISO9001:2008 authentication quality systems.

• we are nominated as the AAA enterprise by Jiangsu government.

• Quick Response to Your Enquiry.

- Q:Can stainless steel bars be used in the manufacturing of chemical reactors?

- Yes, stainless steel bars can be used in the manufacturing of chemical reactors. Stainless steel is known for its corrosion resistance, high temperature resistance, and durability, making it an ideal material for chemical reactors that are exposed to harsh chemicals and extreme conditions. The use of stainless steel bars ensures the longevity and reliability of the reactors, while maintaining the integrity of the chemical processes within.

- Q:Are stainless steel bars suitable for pharmaceutical packaging equipment?

- Pharmaceutical packaging equipment benefits greatly from the use of stainless steel bars. This material is widely recognized in the pharmaceutical industry for its exceptional qualities. Its corrosion resistance is paramount in preserving the integrity, safety, and quality of pharmaceutical products. Furthermore, stainless steel is effortless to clean and sterilize, effectively reducing the risk of contamination. Its strength and durability make it an ideal choice for equipment that must withstand demanding usage and maintain precision. Moreover, stainless steel does not react with most pharmaceutical substances, ensuring that the packaging equipment does not interfere with or compromise the products. In conclusion, stainless steel bars possess the necessary attributes required for pharmaceutical packaging equipment, solidifying their status as an impeccable choice within this industry.

- Q:How are stainless steel bars tested for quality control?

- Various methods are used to thoroughly test stainless steel bars for quality control, ensuring their durability, strength, and resistance to corrosion. One primary test conducted is the examination of the steel's chemical composition to ensure it meets specified requirements. This analysis is crucial as even slight variations in composition can significantly impact bar quality and performance. Another important test evaluates the mechanical properties of the steel bars, including tensile strength, yield strength, elongation, and impact resistance. These tests determine the bars' ability to withstand external forces and stresses. To assess resistance to corrosion, stainless steel bars undergo testing in corrosive environments, such as salt spray exposure, to evaluate long-term performance. This ensures the bars can withstand harsh conditions without deterioration or rust. Dimensional inspection is also carried out to verify that bars meet required size and shape specifications. Length, diameter, straightness, and surface finish are measured, and any deviations from specified dimensions are thoroughly examined and rectified to maintain high-quality standards. Additionally, non-destructive testing methods are used to detect internal or surface defects. Techniques like ultrasonic testing, magnetic particle inspection, and dye penetrant testing identify cracks, voids, or other imperfections that may compromise bar quality and integrity. All tests are conducted in accordance with international standards and guidelines to ensure consistency and reliability in the quality control process. By subjecting stainless steel bars to comprehensive testing procedures, manufacturers can guarantee that the bars meet desired quality standards and are suitable for various applications in construction, manufacturing, and infrastructure industries.

- Q:Are stainless steel bars suitable for chemical processing applications?

- Stainless steel bars are indeed appropriate for chemical processing applications. Renowned for its outstanding resistance against corrosion, stainless steel demonstrates remarkable durability against chemical reactions and harsh surroundings. Moreover, it can endure high temperatures and pressures, rendering it an optimal material for chemical processing tools like tanks, reactors, and pipes. Furthermore, stainless steel bars can be effortlessly cleaned and sterilized, a crucial aspect in upholding the purity and integrity of chemical procedures. All in all, stainless steel bars present themselves as a trustworthy and long-lasting option for chemical processing applications.

- Q:Can stainless steel bars be used in the food processing manufacturing industry?

- Stainless steel bars are indeed applicable in the food processing manufacturing industry. This particular industry favors stainless steel due to its myriad advantageous attributes. Its resistance to corrosion is paramount when handling food and liquids. Moreover, stainless steel exhibits exceptional tolerance to both extreme heat and cold, rendering it suitable for a vast array of food processing tasks. Furthermore, stainless steel is effortless to clean and uphold, guaranteeing impeccable hygiene standards and preventing contamination. Additionally, its durability enables it to endure intensive usage and frequent cleaning. Consequently, stainless steel bars emerge as a dependable and secure option for deployment in the food processing manufacturing industry.

- Q:Are stainless steel bars suitable for decorative applications?

- Stainless steel bars are a great choice for decorative purposes. This material is versatile and durable, with a sleek and modern look. It is commonly used in architecture, interior and exterior decoration, furniture, and artwork. You can polish stainless steel bars to a high shine, giving them a reflective and lustrous finish that adds elegance to any space. They can also be brushed or textured to create different visual effects, offering a wide range of design options. One of the main advantages of stainless steel is its resistance to corrosion and staining. This means that the bars will maintain their aesthetic appeal even in tough environments. They are suitable for both indoor and outdoor decorative applications, as they can withstand moisture, sunlight, and harsh weather conditions. Additionally, stainless steel is a strong and long-lasting material. This ensures that the decorative bars will remain structurally intact over time. They are perfect for high-traffic areas or installations where they may come into physical contact. In conclusion, stainless steel bars are a great choice for decorative applications. They offer a combination of aesthetic appeal, durability, and resistance to corrosion. Whether it's for architecture, furniture, or artwork, stainless steel bars can enhance the visual appeal of any space while ensuring long-lasting beauty.

- Q:What is the difference between round and square stainless steel bars?

- The main difference between round and square stainless steel bars lies in their shape. Round stainless steel bars have a circular cross-section, while square stainless steel bars have a square cross-section. This shape difference affects their applications and structural properties. Round bars are commonly used in construction, industrial, and manufacturing sectors for applications such as shafts, fasteners, and structural components. Square bars, on the other hand, are often utilized in architectural designs, frames, and braces due to their sharp corners and flat sides that provide enhanced stability and support.

- Q:Can stainless steel bars be used in aerospace manufacturing?

- Yes, stainless steel bars can be used in aerospace manufacturing. Stainless steel is a versatile and widely used material in various industries, including aerospace. It offers a combination of strength, durability, and corrosion resistance, making it suitable for use in aircraft components such as landing gear, engine components, fasteners, and structural parts. Stainless steel bars are often utilized in the manufacturing of structural frames, support structures, and other critical components where high strength and resistance to harsh operating conditions are required. Additionally, stainless steel's ability to withstand high temperatures and its excellent performance in extreme environments make it an ideal choice for aerospace applications.

- Q:Are stainless steel bars suitable for pharmaceutical industry?

- Yes, stainless steel bars are suitable for the pharmaceutical industry. Stainless steel is often used in the pharmaceutical industry due to its excellent corrosion resistance, durability, and hygienic properties. Stainless steel bars are resistant to various chemicals and can withstand high temperatures, making them ideal for use in pharmaceutical equipment such as tanks, reactors, pipework, and storage vessels. Additionally, stainless steel is easy to clean and maintain, ensuring a high level of hygiene and preventing contamination of pharmaceutical products. Overall, stainless steel bars are a reliable and safe choice for the pharmaceutical industry.

- Q:Round stainless steel bar is formed after how to deal with customers?

- We usually is to remove the 2MM, refers to 12 customers, after drawn, will become a round of 10, so the price is high

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

254SMO stainless steel forgings/round bar/rod/pipe fittings

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 260000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords