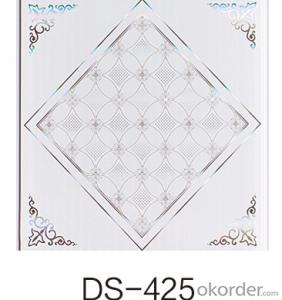

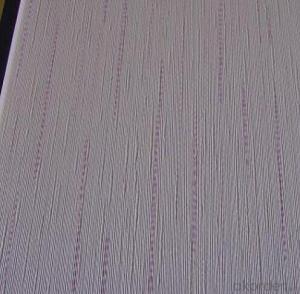

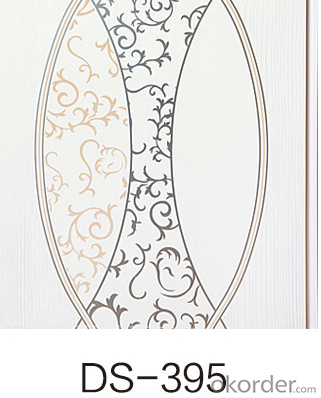

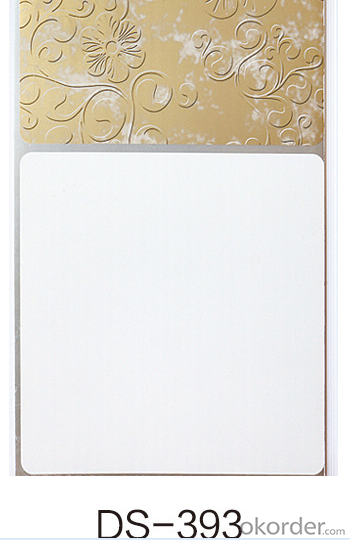

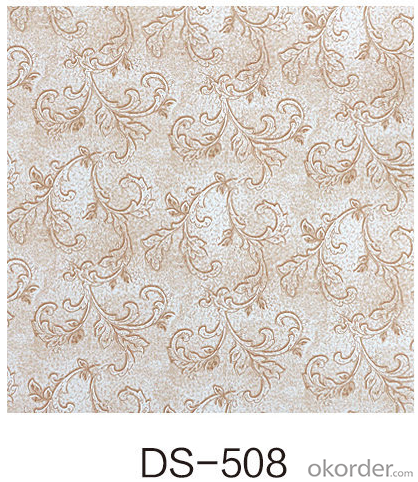

250*7.5mm Radiant Artistic Pvc Ceiling Designs , High Quality Pvc Ceiling Panel China Supplier

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 30000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Type: | Ceiling Tiles, Ceiling Tiles /Wall Tiles | Place of Origin: | Zhejiang, China (Mainland) | Brand Name: | YIYAYU |

| Model Number: | YYY-1156 | Function: | Fireproof, Heat Insulation, Moisture-Proof, Mould-Proof, Smoke-Proof, Sound-Absorbing, Soundproof, Waterproof | Feature: | Artistic Ceilings, Honeycomb Ceilings, Integrated Ceilings, Perforated Ceilings |

| Ceiling Tile Shape: | Rectangle | Ceiling Tile Type: | PVC Ceilings | Length: | 2900-5950mm |

| Color: | as catalog | Thickness: | 7.5mm | Width: | 250mm |

| Surface: | hot stamping | Item: | pvc panel | Weight: | 2.5kg/sqm |

Packaging & Delivery

| Packaging Details: | Bales of shrink:10pcs per bale or customized design Carton:10pcs per carton or customized design PE film PS:Each kind of packages can be with customers' own trade marks and brand names. |

| Delivery Detail: | Within 15 days after prepayment for one 40 feet container |

FAQ

· Can we make an OEM order?

o We can offer or supply goods as customers' requirements.

· How can I get some samples? Free or not?

o We can send some normal samples, absolutely free.

· How does your factory do regarding quality control?

o "Quality is priority." We always attach great importance to quality controlling from the very beginning to the very end. Our factory has gained ISO9001 , SGS authentication, CE for Europe, etc.

- Q:Will the kitchen toilet ceiling, with aluminum plate is good or good PVC?

- Of course, is the aluminum plate. PVC is cheap, but the quality is far less than aluminum plate.

- Q:a restaurant that is partailly elevated. Is heat tape 'really' nessessary? If I wrap it tightly with insulatin then wrap it again with a plastic flex wrap, that ought to be okay, right? I'm not a plumber- just a basic maint. man. Any tips, ideas?

- That is unusual. I believe that insulation would be enough. I've only used heat tape on water lines, not drains. The main issue here is to eliminate any breeze or drafts that may be occurring. Make sure that any cracks or openings that may allow the wind in are sealed up. In my experience it is almost always the direct cold air from wind that causes any freezing. Good luck.

- Q:What is the difference between WPC and PVC flooring?

- WPC refers to the wood-plastic composite flooring, may be PVC / PE / PP + wood powder made out. PVC is PVC plastic, ordinary PVC flooring may not add wood powder.

- Q:Do blister light with 5 mm PVC board when the bottom plate, no knife cut there is no good way to quickly repair the bottom

- Cut with a cutting machine just fine, as long as the file to do a good floor can also be engraved with engraving machine

- Q:Members XDJM: I work for reasons, a set of home hair blank room idle, recently wanted to simply rent out the rent. A friend said that the floor can be used home PVC floor shop, but we do not understand these things, please help my friends to answer my question, thank you: 1, the thickness of the general requirements of home PVC floor is how much? Requirements can not be easily trampled, hit rotten. 2, PVC floor of the construction conditions is what? Molding room floor can be used directly? 3, my home or the developer of the floor when the developer, the cement is not particularly flat (there are more holes, as if there is no cement road level), with what 4, some people say to brush plastic, need not? Hope that these or their own use of the reply, I only 30 points, all the reward

- You installed PVC flooring this time. After their own living and then re-decoration can also continue to use. This is more wearable. The effect is very good.

- Q:How does PVC hardness dictate?

- PVC, the full name of Polyvinylchlorid, the main ingredient for the polyvinyl chloride, in addition to other ingredients to enhance its heat resistance, toughness, ductility and so on. The top layer of this surface film is a paint, the middle of the main component is polyvinyl chloride, the bottom is the back coating adhesive

- Q:Pvc floor leather cement can paste it?

- PVC floor leather cement can be shop. ???? Pvc floor leather, also known as coil flooring, is a new type of flooring materials, is based on polyvinyl chloride (PVC) as the main material, adding appropriate additives, in the continuous sheet of the substrate by coating or rolling process production Of the floor roll. Thickness of 1.5 mm or more, wear-resistant layer 0.1 or more. ???? Pvc floor leather in the international developed countries is the mainstream material, widely used in homes, offices, supermarkets, hospitals, schools and other places, is a new environmentally friendly materials.

- Q:I have a blank PVC gusset plate, plastic material. I want to buy some heat transfer film transfer up, but do not know what equipment through the heat, the general plane thermal transfer machine can it? I am worried that the plastic buckle into the thermal transfer equipment will heat deformation. Please recommend a transfer on the plastic equipment, thank you! Do you buy some blank thermal transfer film through the printer can be printed after the thermal transfer to plastic up?

- Now many do not use the heat transfer, and that too much trouble, you can directly use uv digital printing presses. That is dry, the effect is very good. Small 6090 universal printer, printing format 60cm * 90cm, double DX5 nozzle, priced at 5.5w. Printing speed of 2-6 square meters / hour. Printing field with mobile phone shell, leather, handicrafts, high-precision business equipment.

- Q:What are the shortcomings of PVC products? The more detailed the better.

- Our company is producing pvc glue, I can only provide me to understand. Pvc is a very stable material, mainly used in our sewers and flooring, acid and alkali, wear insulation, durable than iron, is not easy to be corroded, but there are professional solvent dissolved, so link stitching more convenient, these are advantage. Pvc according to different uses to join different additives, showing different physical properties and chemical properties. Because pvc is a general plastic material that is afraid of high temperature, the number of additives added to the pvc material determines the hardness and softness, determines the degree of oxidation. So pvc generally afraid of high temperature, afraid of a specific solvent, afraid of light easily oxidized. These are shortcomings.

- Q:Can Alcohol Clean Pvc Plate?

- Of course, but to use the high concentration, preferably more than 95%.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

250*7.5mm Radiant Artistic Pvc Ceiling Designs , High Quality Pvc Ceiling Panel China Supplier

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 30000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords