20mnsi Q235 Square Bar Steel Billets 3SP 5SP 20MnSi for Ceramic Tunnel Kiln

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

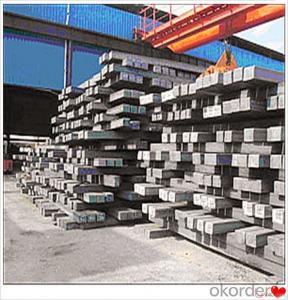

20mnsi Q235 Square Bar Steel Billets 3SP 5SP 20MnSi for Ceramic Tunnel Kiln

Description

Reference Price:$260/ton Mn 0.3%-0.6%

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Processing of Steel Billet

Steel billets are considered fresh and raw, and they must undergo a series of manufacturing processes before they can be used for various purposes. Billets are made by means of freezing molten liquid, and are later exposed to extremely low temperatures in order to allow the metal to take shape and solidify in chemical structure. The temperature manipulates the metal's physical properties, and tones its strength and durability. The subsequent processes provide the metal's curved mold design so that it can fit the allotted space provided by other machines, which complete the finishing procedures.

Images

Technical Data

Size:100*100,120*120,150*150,130*130

Mn: 0.3%-0.6%

C: 1%

Cr:0.1%

Packaging

cargo ship or container

usually container price will add 15USD per ton

RFQ

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! steel billets/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

If you are interested in our products, please don't hesitate to contact me.

Your any inquiry will be appreciated and we will offer you a rock-bottom price.

- Q:How are steel billets used in the automotive industry?

- Steel billets are an essential component in the automotive industry and are used in various applications due to their strength, durability, and versatility. These billets are primarily used to manufacture various parts and components of automobiles, ranging from chassis and engine parts to suspension systems and body panels. One of the key uses of steel billets in the automotive industry is in the production of crankshafts, which are crucial for converting the reciprocating motion of pistons into rotational motion. Crankshafts need to withstand high levels of stress and pressure, and steel billets provide the necessary strength and resilience to meet these requirements. Similarly, steel billets are used to manufacture camshafts, which control the opening and closing of the engine's valves. Camshafts require high precision and durability to withstand the continuous mechanical stresses, and steel billets offer the necessary mechanical properties to ensure their reliability. Furthermore, steel billets are commonly employed in the production of various suspension components, such as control arms and axle shafts. These components need to withstand heavy loads and shocks while maintaining structural integrity, making steel billets an ideal material choice. In addition, steel billets are utilized in the manufacturing of body panels, such as doors, hoods, and fenders. These parts require high strength to ensure passenger safety and withstand impacts, and steel billets provide the necessary strength while also offering cost-effectiveness. Moreover, steel billets are used in the production of transmission components, including gears and shafts. These parts require high strength, wear resistance, and dimensional accuracy, which are all provided by steel billets. Overall, steel billets play a crucial role in the automotive industry, enabling the production of various components and parts that require exceptional strength, durability, and precision.

- Q:What are the different types of surface finish methods used for steel billets?

- There are several types of surface finish methods used for steel billets, including hot rolling, cold rolling, sandblasting, polishing, and galvanizing.

- Q:What are the different surface treatments available for steel billets?

- Steel billets can undergo various surface treatments, each with its own purpose and benefits. Some commonly used treatments include: 1. Hot-dip galvanizing: By immersing steel billets in molten zinc, a protective coating is formed to prevent corrosion. This treatment offers excellent corrosion resistance and durability, making it suitable for outdoor use. 2. Electroplating: Through the application of an electrical current, a layer of metal is deposited onto the surface of steel billets. This treatment enhances the appearance of the steel while providing corrosion and wear resistance. 3. Powder coating: This dry finishing process involves electrostatically applying a fine powder to steel billets, which is then cured under heat. The result is a durable and visually appealing finish that is resistant to chipping, scratching, and fading. 4. Passivation: By chemically treating steel billets, contaminants are removed and a protective oxide layer is formed on the surface. This enhances corrosion resistance and improves appearance. 5. Phosphating: Steel billets can undergo a treatment where a phosphate coating is applied, enhancing corrosion resistance and paint adhesion. This treatment is commonly used as a pre-treatment before painting or powder coating. 6. Shot blasting: This mechanical treatment involves blasting steel billets with small abrasive particles at high velocity. It effectively removes surface contaminants, scales, and rust, resulting in a clean and rough surface suitable for further treatments or coatings. 7. Acid pickling: By chemically treating steel billets, oxide scales, rust, and impurities are removed, leaving behind a clean and smooth surface. This treatment prepares the steel for subsequent processing or coating. These treatments are just a few examples of what can be done to steel billets. The choice of treatment depends on specific requirements, such as corrosion resistance, appearance, and functional properties. Factors like cost, environmental impact, and performance expectations should be considered when selecting the appropriate surface treatment for steel billets.

- Q:What are the different surface treatments applied to steel billets?

- Depending on the desired outcome and application, steel billets can undergo several different surface treatments. Some common treatments include: 1. Shot Blasting: This method involves propelling small metal or mineral particles onto the steel billet surface at high speeds. Shot blasting effectively removes surface impurities like rust or scale, resulting in a clean and even surface. 2. Pickling: Pickling is a chemical treatment that submerges the steel billets in an acid solution, usually hydrochloric or sulfuric acid. This process eliminates oxide layers or scale from the billet surface, leaving it clean and smooth. 3. Phosphating: Phosphating is a chemical conversion coating process that involves immersing the steel billets in a solution containing phosphate salts. This treatment forms a thin, corrosion-resistant phosphate film on the surface. 4. Galvanizing: Galvanizing is a widely used surface treatment for steel billets, where a layer of zinc is applied. This process provides excellent corrosion protection and enhances durability. 5. Painting: Another common surface treatment is painting, where a layer of paint is applied to the steel billet surface. This not only enhances aesthetic appeal but also provides additional corrosion protection. 6. Electroplating: Electroplating involves depositing a thin layer of metal, such as chromium or nickel, onto the steel billet surface using an electrical current. This treatment improves appearance, corrosion resistance, and wear resistance. It is important to consider factors like intended use, environmental conditions, and cost when selecting a surface treatment for steel billets. Each treatment offers specific benefits, so choosing the most suitable option ensures optimal performance and longevity.

- Q:How do steel billets contribute to the overall fire resistance of a structure?

- The overall fire resistance of a structure is enhanced by steel billets in several ways. Firstly, steel billets are made of a non-combustible material, meaning they cannot burn or aid in the spread of fire. By incorporating steel billets into a building's construction, the risk of fire propagation is significantly reduced. Secondly, steel possesses a high melting point, typically around 1370 degrees Celsius. This characteristic enables steel to maintain its structural integrity and resist deformation even under intense heat. By using solid steel blocks, known as steel billets, the structure gains strength and stability that can withstand the impact of a fire. Moreover, steel exhibits low thermal conductivity, resulting in poor heat conduction. This property helps to slow down the transfer of heat from the fire to the surrounding areas of the structure. By acting as a barrier, steel billets hinder rapid temperature rise, allowing occupants more time to evacuate and firefighters more time to extinguish the fire. Furthermore, steel billets are frequently utilized in constructing fire-resistant walls or barriers within a structure. These walls are designed to compartmentalize the building, confining the spread of fire and smoke to specific areas. By incorporating steel billets into these fire-resistant walls, the overall construction becomes more durable and capable of enduring the extreme conditions of a fire. In conclusion, steel billets play a crucial role in enhancing the overall fire resistance of a structure due to their non-combustible nature, high melting point, low thermal conductivity, and ability to reinforce fire-resistant walls. By incorporating steel billets into the construction process, buildings can achieve greater resilience against fire incidents, ensuring the safety of occupants and minimizing fire damage.

- Q:What are the common defects in billet? What's the cause?

- 4. Tungsten inclusion;Six, arc scratch and heat crack and overlap: 1:Two reheat cracks 3 cracks

- Q:What are the different grades of steel billets?

- There are several different grades of steel billets, including low carbon steel, medium carbon steel, high carbon steel, alloy steel, and stainless steel. The specific grade of steel billet used depends on the intended application and desired properties of the final product.

- Q:How are steel billets used in the manufacturing of wire rods?

- Steel billets are an integral part of the manufacturing process for wire rods. These billets, which are essentially semi-finished steel products, serve as the raw material for producing wire rods. The first step in the manufacturing process involves heating the steel billets to a high temperature in a furnace. This process, known as heating or re-heating, helps to soften the steel and make it more malleable. Once the billets are heated, they are then passed through a series of rolling mills. In these mills, the billets are subjected to intense pressure and are gradually shaped into wire rod form. The rolling process elongates the steel billets and reduces their diameter to the desired size. After the initial rolling, the wire rods undergo further processing to enhance their strength, surface finish, and dimensional accuracy. This may involve various techniques such as cooling, heat treatment, and surface conditioning. Finally, the wire rods are cut into specific lengths and undergo quality control checks to ensure that they meet the required standards. They are then ready to be used in various applications such as construction, automotive, and electrical industries. In summary, steel billets play a crucial role in the manufacturing of wire rods. They are heated, rolled, and processed to create wire rods of different sizes and properties. These wire rods are then used in a wide range of industries, making them an essential component in the manufacturing sector.

- Q:How are steel billets used in the manufacturing of automotive components?

- Steel billets are used in the manufacturing of automotive components as the starting material for various forging and machining processes. These billets are heated, shaped, and then further processed to create different automotive parts like crankshafts, connecting rods, gears, and axles. The high strength and durability of steel make it an ideal choice for these critical components, ensuring the safety and performance of vehicles.

- Q:For example, screw plate (PU plate and manganese plate), carbon steel Primeton is what person rolling out?.

- Primeton Pu board generally refers to A3; carbon steel refers to the high quality carbon steel, such as No. 45 steel, 35 steel and so on; that in addition to the carbon and other elements, such as Cr, Mo etc., in which the carbon ratio below 30 for low alloy steel

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

20mnsi Q235 Square Bar Steel Billets 3SP 5SP 20MnSi for Ceramic Tunnel Kiln

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords