2016 pvc foam sheet for furniture wall almirah designs

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 866 pc

- Supply Capability:

- 10000 pc/month

- Option:

- as your request

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

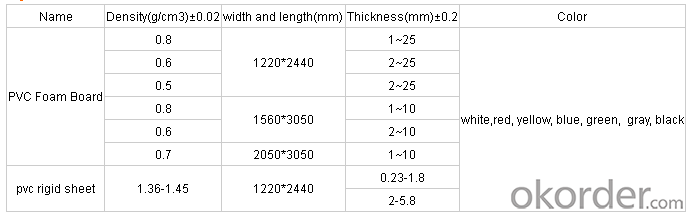

1.Product Specification

Regular size: 1220*2440mm,1560*3050mm,2050*3050mm

Thickness:1-33mm

Density:0.35-0.9

2.Product Uses

1 mm- 5 mm: suitable for advertising supplies, electronic instrument, packaging

15 mm -20 mm: suitable for furniture

10 mm -20 mm: suitable for bath cabinet, cabinets

5 mm- 20 mm: exhibition board, indoor and outdoor decorative plate (different customers have different requirements)

3 mm coated :bus interior ceiling

3.Good performance:

1, plastic coating, membrance-stuck and printing

2, with the usual equipment and tools, it can be processed again.

3, welding and bonding

4, cutting and sawing

5, bending when heated-up, thermal forming

6, hole-drilling, Channeling and die cutting

7, nail, wrest and rivet

4. Product Application

(1) Advertising: exhibition display, digital printing, silk screen printing, computer lettering,sign board, light box,etc.

(2) Construction: office and bathroom cabinets, inner and outer decorate panel,commercial decorating shelf, room separating

(3) Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layerand other industry.

5.FAQ

Q: If the products have some quality problem ,how will you deal with it?

A:If the quality problem caused by us, we will provide a replacement service,and we must keep in mind.

Take measures to control quality strictly,we adhere to the principle: “ quality first”.

Q: Is free design assistance available for clients?

A: If you have problems in designing or beautifying the customized product,

we will offer you the best design assistance.

- Q:Can plastic sheets withstand high temperatures?

- Yes, plastic sheets can withstand high temperatures depending on the type of plastic used. Some plastics, such as polypropylene and polyethylene, have relatively low melting points and may deform or melt at high temperatures. However, there are heat-resistant plastics, like polycarbonate and polyimide, that can withstand elevated temperatures without losing their structural integrity.

- Q:How long do plastic sheets typically last?

- The lifespan of plastic sheets can vary depending on various factors such as the type of plastic used, the quality of the sheet, and the conditions in which it is used. However, on average, plastic sheets can last anywhere from a few years to several decades.

- Q:Are plastic sheets resistant to moisture?

- Yes, plastic sheets are generally resistant to moisture.

- Q:Can plastic sheets be used for DIY storage bins?

- Yes, plastic sheets can be used for DIY storage bins. They are durable, easy to cut and shape, and can be customized to fit specific storage needs.

- Q:What are the kinds of plastic sheets?

- Electronic industry protection. Conductive packaging products mainly used in packaging, IC packaging, IC wafer testing, TFT-LCD, optoelectronics and other electronic components, the purpose is to avoid contact with other charge items, causing parts for electric spark friction. In addition, there are conductive, anti-static plastic plates, turnover boxes and so on.

- Q:Put drops of water on glass or plastic sheet. After evaporation we see white soft dust there. What's that?

- If it was pure water, and there was no dust present in the room there should be no dust. But if it's tap water that is most likely lime deposits or deposits from the minerals in the water. Try the same experiment with distilled water (not bottled drinking water, because minerals are added).

- Q:Do plastic sheets have any impact on the environment?

- Yes, plastic sheets have a significant impact on the environment. They are typically made from non-biodegradable materials, such as polyethylene or polypropylene, which can take hundreds of years to decompose. When these sheets are disposed of improperly, they can end up in landfills, oceans, or natural habitats, contributing to pollution and harming wildlife. Additionally, the production of plastic sheets requires the extraction of fossil fuels and the release of greenhouse gases, contributing to climate change.

- Q:Are plastic sheets flammable?

- Yes, plastic sheets can be flammable. The flammability of plastic sheets depends on the type of plastic used and its composition. Some plastics are more flammable than others, and if exposed to high heat or an open flame, they can ignite and burn.

- Q:Are plastic needlepoint mesh sheets food grade?

- They are not RATED as food grade, but as with many plastics they can be used around food if washed and sanitized regularly. Examples: plastic bowls cutting boards plastic knife and fork handles etc., etc.

- Q:Can plastic sheets be used for protective film applications?

- Yes, plastic sheets can be used for protective film applications. Plastic sheets are often used as a cost-effective solution to protect surfaces from scratches, stains, and other damages. They can be easily applied and removed, providing temporary or long-term protection for a variety of surfaces such as windows, floors, furniture, and electronic screens.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

2016 pvc foam sheet for furniture wall almirah designs

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 866 pc

- Supply Capability:

- 10000 pc/month

- Option:

- as your request

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords