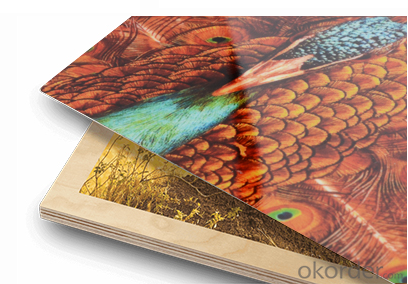

2016 Manufacturer Four Colors And Spot Color Hd Metal Print

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 carton

- Supply Capability:

- 20000 carton/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Description:

These Aluminum Panels can provide for many sizes and different color. It can suitable in many occasion, like company logo screen, show backdrop, home use, some gift use etc. We can also provide the heat press machine for transferring.

Features:

1. Extremely durable scratch resistant surface that is waterproof and can be cleaned easily with a damp cloth.

2. Eco-friendly & Terrific as a decoration.

3. Longest lasting photo medium in the current market.

4. The high definition, vibrant colors coupled with superior fade, moisture, stain & scratch resistant properties.

5. The image is infused into the coating to provide permanent protection and durability.

6. Excellent choice for commercial, fine art, and home decoration applications.

Making Process:

1. Get images from digital camera, memory card or scanner.

2. Print image with heat transfer paper and sublimation ink.

3. Lay down a teflon sheet and your panel, and another CLEAN teflon sheet on top, pre-press for 60 sec., 180℃, 0.3Mpa.

4. 60 seconds later. Wait the panel to cool.

5. Tape the transfer to the face of the substrate with heat resistent tape running parallel to the edge of the substrate.

6. Lay substrate face up, transfer on top on a piece of telfon sheet on lower platen.

7. Cover with one layer of fabric, preferably 100% polyester or poly-silk, to distribute pressure and reduce stress on the coating.

8. Press for the prescribed time is 130sec., temperature is 180℃ and pressure is 0.3Mpa.

9. When finished, remove the fabric and gently peel the taped transfer off the substrate without allowing it to slide or move.

10. Let the substrate to cool. Do not handle it until cool to reduce the chances of damaging the coating on the edges.

11. Enjoy your personal designed aluminum board!

- Q:What is the difference between the alloy 1060H24 aluminum plate and the alloy 1100H24 aluminum plate?

- At present, most of the circulation in the market is 1050 and 1060 series. 1000 series aluminium plate to determine the minimum aluminum content in this series according to the amount of the last two Arabia figures, such as the 1050 series of the last two Arabia number 50, according to the international brand naming principles, content must reach 99.5% to the top for qualified products. China's aluminum alloy technology standard (gB/T3880-2006) is also clearly defined, 1050 aluminum content of 99.5%., the same reason, 1060 series aluminum plate aluminum content must reach more than 99.6%

- Q:Are aluminum sheets suitable for aerospace applications?

- Yes, aluminum sheets are highly suitable for aerospace applications. Aluminum is widely used in the aerospace industry due to its excellent combination of strength, lightweight properties, and corrosion resistance. Its high strength-to-weight ratio makes it an ideal choice for constructing aircraft structures, including fuselages, wings, and other critical components. Aluminum sheets also offer good formability, allowing for complex shapes to be easily manufactured. Additionally, aluminum has good thermal conductivity, which is beneficial for heat dissipation in aerospace applications. Overall, aluminum sheets meet the stringent requirements of the aerospace industry and are extensively utilized in the construction of modern aircraft.

- Q:I did electrolysis by adding aluminum to the ends of the wire. I waited about 2 hours, and then I filtered the water. After it dried, I was left with powder. It's gray.It that aluminum powder or something else? I'm making thermite, if its not aluminum powder will it still work?

- Kinda sorta, the problem with this is that all you did was made aluminium oxide or hydroxide, when you electrolyzed the aluminium you also electrolyzed a bit of water with it, which added a hydroxyl group to the aluminum, which may have dropped a hydrogen when you dried it. If you could find an aluminium compound that is water soluble (DAMNED HARD to find) you could electrolyze it in water to get aluminium dust in the water, but that isnt very reliable or economical, the best thing for you to do is to get a ball mill or rock tumbler, add aluminium fold and about half full of regular marbles, let it run for 3 or so weeks. You need it really fine!

- Q:there is a magnet for other type of nails except aluminum nails

- Not that I have heard of. The best way is manual hand pick up. If it is on concrete you might try making a pad out of a good stickey tape (turning the stickey part to the outside) that might speed up the process.

- Q:What is the main influence of the spacing?What are the main effects of spacing?

- Thermal explosion is related to a lot of factors. As to how much impact the lining board has on the thermal explosion, it's really impossible to speak of it. I think it has very little influence

- Q:I have a specific design I'd like to cut out of thin sheet metal (aluminum or tin) and I'm wondering how to make it more sturdy. The sheet metal is a bit flimsy. Can I strengthen it by heating it up (butane torch) and cooling it quickly?

- This Site Might Help You. RE: Can you temper aluminum or tin? I have a specific design I'd like to cut out of thin sheet metal (aluminum or tin) and I'm wondering how to make it more sturdy. The sheet metal is a bit flimsy. Can I strengthen it by heating it up (butane torch) and cooling it quickly?

- Q:What is the weight of aluminium plate now?

- The following is the density of each series of aluminum sheets for reference.Pure aluminum 2.7 TC7 4.4Antirust aluminium LF2, LF43 2.68, TC8 4.48LF3 2.67 TC9 4.52LF5, LF10, LF11 2.65, TC10 4.53LF6 2.64 pure nickel, anode nickel, electric vacuum nickel 8.85LF21 2.73, nickel, copper, nickel, magnesium, nickel silicon alloy 8.85Hard aluminium, LY1, LY2, LY4, LY6 2.76, Ni Cr alloy 8.72LY3 2.73 (Zn0.1, Zn1, zinc, Zn2, Zn3) 7.15LY7, LY8, LY10, LY11, LY14 2.8, cast zinc 6.86LY9, LY12 2.78, 4-1 casting zinc aluminum alloy 6.9LY16, LY17 2.84, 4-0.5 casting zinc aluminum alloy 6.75Wrought aluminium LD2, LD30 2.7 lead and lead antimony alloy 11.37LD4 2.65 lead anode plate 11.33LD5 2.75

- Q:why does aluminum sheet not react with sulfuric acid nut react with hydrochloric acid?

- aluminum reacts with hydrochloric acid,generating aluminium chloride which can dissolve in water. but aluminum reacts with sulfuric acid, generating aluminum sulfate which can't dissolve in water and will generate aluminum sulfate, a layer of protective film, preventing aluminum from reacting with sulfuric acid, so there is no significant phenomena.

- Q:Can aluminum sheets be used for architectural applications?

- Architectural applications can definitely make use of aluminum sheets. Aluminum, being a lightweight and versatile material, offers numerous advantages for architectural projects. It possesses durability, resistance to corrosion, and the ability to withstand extreme weather conditions, making it an ideal choice for different architectural applications like roofing, cladding, facades, windows, doors, and decorative elements. The availability of aluminum sheets in various thicknesses, finishes, and colors allows architects and designers to achieve their desired aesthetic while maintaining structural integrity. With the material's flexibility in being easily shaped, bent, and formed into complex designs, architects are provided with creative freedom and flexibility. Aside from its aesthetic appeal, aluminum is also an environmentally sustainable choice for architectural applications. It is highly recyclable, contributing to a high recycling rate and promoting eco-friendly options. The use of aluminum sheets in architectural projects helps in reducing the carbon footprint and promoting sustainable design practices. Moreover, aluminum sheets offer excellent thermal and acoustic properties that contribute to energy efficiency and sound insulation in buildings. The material aids in reducing energy consumption and enhancing occupant comfort, making it an attractive option for architects and building owners. In conclusion, the versatility, durability, sustainability, and aesthetic appeal of aluminum sheets make them a popular choice for architectural applications. They provide numerous benefits and can be utilized in various ways to create stunning architectural designs while ensuring long-lasting performance.

- Q:Are aluminum sheets suitable for high-pressure environments?

- Aluminum sheets are generally not suitable for high-pressure environments as they have a relatively low strength-to-weight ratio compared to other materials. This means that they may deform or fail under high pressure, leading to potential safety risks. Additionally, aluminum has a relatively low melting point, which can further compromise its structural integrity in high-pressure situations. In such environments, materials with higher strength and resistance to deformation, such as steel or titanium, are typically preferred.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

2016 Manufacturer Four Colors And Spot Color Hd Metal Print

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 carton

- Supply Capability:

- 20000 carton/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords