2016 High Quality Injection Molding Machine LOG-650A8

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

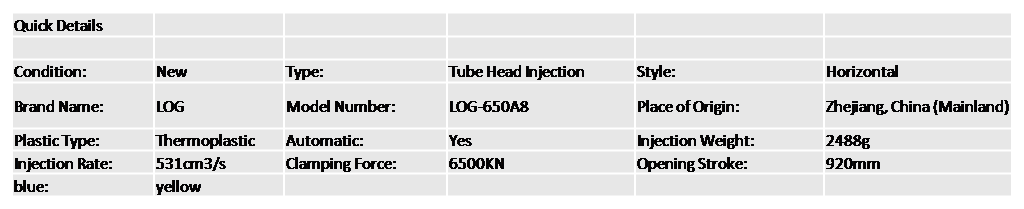

| LOG-650A8 | ||||

| International size rating | 4640/650 | |||

| INJECTION | A | B | C | |

| Shot volume | cm3 | 2160 | 2734 | 3376 |

| Shot weight | G | 1966 | 2488 | 3072 |

| OZ | 68.8 | 87.1 | 107.5 | |

| Screw diameter | mm | 80 | 90 | 100 |

| Injection pressure | mpa | 215 | 170 | 138 |

| Screw L:D ration | 21:01 | 21:01 | 19:01 | |

| Screw stroke | mm | 430 | ||

| Screw speed(stepless) | r/min | 0-125 | ||

| CLAMPING UNIT | ||||

| Clamping force | kn | 6500 | ||

| Opening stroke | mm | 920 | ||

| Platen size | mm×mm | 1320X1290 | ||

| Space between fie bars | mm×mm | 930X900 | ||

| Mold fhickness(Min-Max) | mm | 350-910 | ||

| Max.daylingt | mm | 1830 | ||

| Hydraulic ejection stroke | mm | 265 | ||

| Hydraulic ejection force | kn | 182 | ||

| POWER UNIT | ||||

| Hydraulic system pressure | mpa | 17.5 | ||

| Pump motor | kw | 55 | ||

| Heating capacity | kw | 38.3 | ||

| Number of femp confrol zones | \ | 6+ nozzle | ||

| GENERRL | ||||

| Dry-cycle fime | Sec | 6 | ||

| Oil fank capacify | λ | 1500 | ||

| Machine dimensions | m×m×m | 9.6X1.9X2.3 | ||

| Machine weight | kg | 36000 | ||

Packaging & Delivery

| Packaging Details: | one machine should shipped in a 40GP and a 20 GP containers |

| Delivery Detail: | a week if it's at stock OR a month |

Specifications

1.high response 2. high precise,3oil saving 4. water saving 5 long warking life

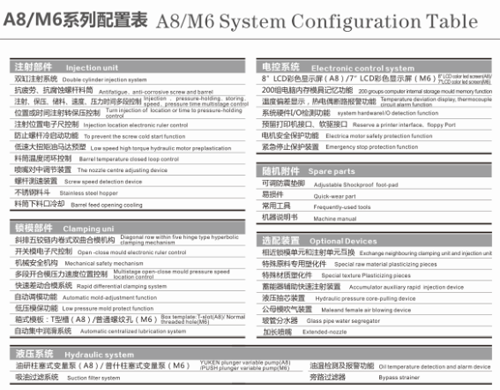

1.template structure of the high-rigidity design,with a bigger clamiping unit. 2. T- slots and conventional screw holes make mold is easy to install. 3 by using our patent bridge structure ,the injection unit will be more stable 4, equipped with imported low-noise and high efficiency variable pump system,saving energy 30% to 60% and and 20 %~40% oil and water 5. high-efficiency filter makes the hydraulic oil clean and a long working life 6. the color screen control system, is conventional to operate it.

- Q:How to install filter screen for injection machine nozzle?

- There are special filter nozzle, used for recycling materials, can protect the mold and hot runner, with few manufacturers.

- Q:How big is the minimum injection molding machine?

- Industrial products, minimum injection molding machine, about 12-15 grams [injection volume]If used in scientific research, it can be made specially,

- Q:What is low voltage protection (injection molding machine)?

- For example, when there is something on the surface of the mold to fit the mold, it will open the mold automatically in order not to damage the mold. This process is low voltage protection.

- Q:Can carbon fiber be used for injection molding?

- 1 carbon fiber can be used for injection molding.2, carbon fiber (carbon fiber, referred to as CF), is a carbon content of more than 95% of high strength, high modulus fibers of new fibers. It is a flaky graphite, microcrystalline and other organic fibers stacked along the axial direction of the fiber, obtained by carbonization and graphitization of microcrystalline graphite material. Carbon fiber "an hand in a velvet glove lighter than aluminum," the quality, but the strength is higher than that of steel, and has the characteristics of corrosion resistance, high modulus, in the national defense and civilian areas are important materials. It has not only the intrinsic characteristics of carbon materials, but also the softness and processability of textile fibers. It is a new generation of reinforced fiber.3 、 injection molding is an industrial product modeling method. Products are typically molded by rubber injection and plastic injection. Injection molding can also be divided into injection molding, die casting and die casting. Injection molding machine (referred to as the injection molding machine or injection molding machine) is plastics molding equipment of thermoplastic or thermosetting material using plastic mold made of various shapes, injection molding by injection molding machine and mold.

- Q:How to adjust the injection molding machine, how to solve the shrinkage of injection molding products?

- Shrinkage (Sink, marks, or shrinkage) is one of the defects in injection molding.ApparentThere is a dent in the accumulation area of the surface material of the plastic parts. The shrinkage occurs mainly in the thick part of the plastic wall or in the change of the wall thickness.Physical reasonsWhen the product is cooled, shrinkage (decrease in volume, shrinkage) occurs at the time where the outer wall of the die is frozen first, and the inner center of the work product forms an internal stress. If the stress is too high, it will cause plastic deformation of the outer plastic. In other words, the outer layer will sag inwards. If the shrinkage occurs and the deformation of the outer wall is not stable (as it has not cooled), the pressure shall not be added to the melt and the mold will settle between the die wall and the solidified outer layer of the product.These settlements are usually seen as shrinkage. If the product has a thick cross section, this shrinkage may also occur after demoulding. This is because there is still heat inside, and it passes through the outer layer and heats up the outer layer. The tensile stress produced in the product causes the thermal outer layer to settle inward, forming shrinkage during this process.

- Q:What are the injection molding machine brands in China?

- Can refer to modern plastic injection molding machine brand surveyIn recent years, the rapid development of China's plastics industry has greatly improved the injection molding machine industry. With Europe, the United States, Japan, Korea and many other internationally renowned injection molding machine brand access, as well as the rapid rise of China's injection molding machine enterprises, the market competition is becoming increasingly fierce. In order to help you understand the user China injection molding machine current demand psychology, demand status and dynamic demand, "PT" magazine on the basis of modern plastic Vogel industry media reader huge data resources at home and abroad, 54 injection molding machine brand, in the reader investigation activities brand demand. To improve the accuracy and objectivity of the survey, the survey issued a total of 3000 questionnaires, the main application areas covered by the injection molding machine, including packaging, automotive, household appliances, electronic communication equipment and medical equipment industries. A total of 355 valid questionnaires were received, of which more than 60% of respondents had equipment procurement decision-making rights or advice in the enterprise.

- Q:Can you tell me if there are 350 grams of three injection molding machines? How much? Thank you

- Small equipment each company has also ten it this brand is almost a domestic brand quality and sea character generation

- Q:What exactly does the KO hole in the injection mold mean? Where is the general position?

- Sometimes according to the actual situation of mold to open several KO hole, then to determine the other KO hole position according to the injection molding machine of the dynamic template parameters for dynamic injection molding machine has opened many holes as the top stick.

- Q:Debugging and debugging process of injection molding machine

- Causes and solutions of plastic forming defectsIncorrect operating conditions, damage to the machine and mold will cause a lot of molding defects, the following provides some solutions for reference. In order to reduce down time, reason and can find out the operation problem as soon as possible, the operator should put all the best record in the condition of injection type injection molding condition record table, for days after the reference for problem solving.(1) the finished product is incompleteFault reason handling methodThe plastic temperature is too low to increase the temperature of the fuse tubeThe injection pressure is too low to increase the injection pressureThe amount of injection is not enoughWith the nozzle with the sprue bushing is plastic spill to re adjust its coordinationThe shot time is too short to increase the injection timeThe injection speed is too slow to accelerate the injection speedImproper adjustment of low pressureMold temperature is too low to improve mold temperatureThe mold temperature is uneven, the mold pipe is re adjustedThe exhaust of the mould is not proper, and the proper exhaust hole is installed at the proper placeThe nozzle temperature is not low, and the nozzle temperature is increasedUnequal opening of mold to re release the mold overflow positionThe sprue or overflow is too small to enlarge the sprue or overflowPlastic lubricant does not increase lubricantBack pressure is insufficient, slightly increase back pressureRubber ring, adhesive screw wear, removal, inspection and repairInsufficient injection capacity, replacement of larger specifications of injection molding machinesThe product is too thin and use nitrogen spray

- Q:What is the function of the temperature control box of the injection molding machine? Thank you

- Controlling the temperature of two heating tubes.Chasing the answerThe temperature is too high and too low, the thermostat plays the role of switch heating tube power supply.The heating tube is used to warm the mold

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

2016 High Quality Injection Molding Machine LOG-650A8

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords