2015Hot Sell Traditional wpc fence(CE, ROHS, ISO9001,ISO14001)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

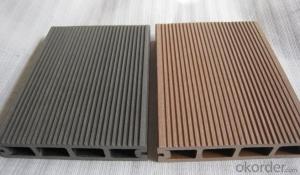

Main Features of the WPC Decking:

1. Recyclable, Eco-friendly, saving forest resources

2. With the look of the natural wood, but less timber problems

3. Moisture/water resistant, less rotten, proven under salt water condition

4. Barefoot friendly, anti-slip, less cracking, less warping

5. Requires no painting, no glue, low maintenance effort

6. Weather resistant, suitable from minus - 40 to 60 centigrade degree

7. Termites and insects resistant, and moldy-proof

8. Easy to install and clean

Specification of the WPC Decking:

component | 30%HDPE(Grade A Recycled HDPE) 60%bamboo/wood fiber component 10%chemical additives New material capped outside |

Size | 140X20mm |

Design | Solid decking |

Length | 2.9m/pc standard length, also from your required |

Surface treament | original, sanded, brushed |

Color available | 5 regular colors for choice ( IPE,Walnut,graystone,Cedar,Rosewood) and we can adjust the new color according to the order requirement |

Cerfiticate | ISO9001, ISO14001, CE, FSC Certificate,"REACH"Test Reports by SGS; Intertek Test Report by ASTM standard..etc. |

Images of Co-extrusion WPC Decking:

FAQ of Co-extrusion WPC Decking :

1. Available Colours?

5 regular colors to choose ( IPE,Walnut,graystone,Cedar,Rosewood )

2. How to Install?

3.Treatment for Option

- Q:What is formaldehyde in the composite floor?

- Of course The

- Q:Home with solid wood flooring and laminate flooring which is good?

- Home with solid wood flooring. Strengthen the floor with a density board to do the substrate, MDF is made of wood powder and plastic pressed, airtight, poor foot feeling, impatience, no moisture, formaldehyde emission is high, the surface is decorated wood grain paper, Filled with aluminum oxide wear layer, wear resistance is better. Install the floor after the main problems in the following areas: ① drums ② deformation ③ cracking and so on. Strengthen the composite floor waterproof moisture resistance is poor, so the installation must be done moisture treatment. So must be installed moisture-proof plastic cloth and PE mats, in order to moisture. In addition, the strengthening of the floor is basically no natural wood flooring has the advantages: sound absorption, antibacterial, rich and so fine. In the case of heating, strengthen the floor prone to drum, deformation and other issues. Solid wood composite flooring is not easy to deformation anti-Alice, good maintenance, not Jiaoqi, etc.: ① solid wood flooring substrate is more than Liu amine, breathable, comfortable better; ② with less glue, better environmental protection; ③ surface with solid wood Thin slices, good-looking, the price is generally lower than similar solid wood flooring; ④ it is generally used UV paint coating, but also the use of ceramic paint, wear resistance are better, but not as good as complex; ⑤ not squeamish, good care. It has a good moisture resistance, because its substrate is the use of criss-cross the willow wood pressed from the wood to eliminate the internal stress.

- Q:Solid wood flooring multi-layer solid wood composite floor to strengthen the difference between the composite wood floor What is the difference between the few? Thank you!

- The difference is very large I do not elaborate on what I am learning this withered cake following the water shortage of the palace of the palace of a professional advice you 1 if used for the bedroom solid wood flooring work what solid wood flooring can not try to not at least us this professional teacher Will not be used in more than 2 layers of solid wood flooring price is relatively low 3 reinforced floor is the MDF veneer bedroom do not use for public indoor places are not waterproof and moisture is mainly wear

- Q:My home is used: Montblanc Teng map of the floor, renovation is less than two months began to drums, there are more than a dozen, looking for after-sales service providers, he said that is engaged in the infiltration of lying lie, Run by water. I do not understand, we engage in cleaning are the first wiping the damp, and then wring dry, if you do so on the drum package, how to do after cleaning? Is there a problem with the quality of the floor? Please enlighten the Supreme more

- If the seams are only a small area of Alice, can be used in heavy pressure on the above, after a period of time after the wooden floor will return to normal. If after a period of time, the seam was drums down, but with the floor before the difference is too far, you can try to wax the floor, waxing after the bubble floor will be almost the same as the original. If it is really very serious, then only to the floor after the sale of the. The The

- Q:Is the composite floor insulator, if the person standing on the composite floor, one hand touch 220V FireWire, will electric shock more

- Insulation, but can not stand touch FireWire

- Q:A television fell during an installation and now I have 2 small divots about the size of a dime in the middle of my newly installed engineered hardwood flooring. How do you repair...or can you?

- Through my experience,you can not really repair the indentions in the wood. Since it is a new floor and you don't want it to be like that forever you can replace that individual board if you have some left and one of the ones that are left are exactly the same size. The installer can cut that board out.....Cut the tongue off of the new and install.He may have to drill a couple of small holes and drive some finish nails but that can be covered with wood putty. ...

- Q:How is the maintenance of the new floor laminate?

- Buy the floor on the Internet Bell, just paved, the new floor needs maintenance? More

- Q:To buy a composite wood flooring, selected a Ruijia light, came back to listen to friends that light is not good, easy to scratches and fade; others say that the light is not the piano light, there will be no fade and wear Open swine swallowed the state of sand and pepper. I can not get it anyway. Please understand the advice of friends, thank you! More

- There are two kinds of bright side of the composite floor, one is the paint, one is wearable paper, which paint the best brightness, but also the most prone to problems, because the paint is not wear, According to the popular argument is that the wear resistance of the paint is about 500 turn, more than 1000 turn. If someone said to be the national standard 4000 or 6000 is the basic determination to lie to you. Another kind of wear-resistant paper is not very standard, because in order to pursue the brightness and clarity, wear-resistant paper can not be thick, otherwise the grain is not clear, so the general surface of the bright side of the board is easy Problem, there is the number of wear-resistant in 2000-3000 turn between, not too high. The state provides a home decoration standards of 4000 and 6000 to two, the general 4000 can be used for more than 10 years is not a problem. If you do not have much to ask for wear and tear, the paper is better than the paint. In addition Kono Senhua floor, a kind of paper wear-resistant, is a large board, 120 long, 16 wide, centimeters, wear degree about 9000 or so, but the price is very expensive, 150-160 or so, to see your personal preferences The. In general, most of the floor of the bright side of the matte side is not as good.

- Q:Will the floor of the floor be poisonous?

- Composite wood flooring environmental standards, but there really do this harm. Composite wood flooring is usually 3 layers, 5 layers or more. Usually solid wood multi-layer composite, as well as non-solid wood multi-layer composite. Layer between the use of glue bonding. To warm the ground will promote the glue and woodworking boards and other artificial wood in the distribution of harmful substances. So if the home to consider the warm, it is best to use three layers of solid wood flooring, less glue content, solid wood does not exist harm.

- Q:When the composite floor assembly can be card into the side slot

- Installed almost the same time

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

2015Hot Sell Traditional wpc fence(CE, ROHS, ISO9001,ISO14001)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords