2015 Green Choice Outdoor WPC/ wood plastic composite (wpc decking)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Wood Plastic Composite Decking

The WPC decking is a new material, combine the nature look of a wood deck with the advantages of a weather-resistant, stable, easy to clean, and sturdy high-tech material and quite follow the trend of wood substitute.

Application of Wood Plastic Composite Decking

widely used for outdoor decking floor,Wall panel.railing,fence,bridge,dock,gloriette,gazebo,boardwalk,etc

Advantage of Wood Plastic Composite Decking

1. With the look of the natural wood but less timber problems, Approx. 90% recycled materials

2. Weather resistant, suitable from -40 to 60 °C

3. Resistant to termite and insect attack, will not split, rot or warp

4. Cuts and drill like timber

5. Requires no painting, no glue, low maintenance effort

6. Easy to install and clean

Packing of Wood Plastic Composite Decking

Packaging Detail | 112pcs per pallet, 16pallets per 20ft, 24 pallets per 40ft. pallet size:290x105x1375px |

Delivery Detail | 15 days after received the deposit |

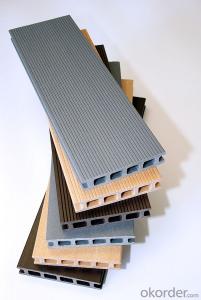

Pictures of Wood Plastic Composite Decking

Specification of Wood Plastic Composite Decking

component | 30%HDPE+60%bamboo/wood fiber component+10%chemical additives |

Length | 2.2m, 2.9m, and 5.8m or customized |

Size | 140X20mm,150X25mm,145 X21mm,145 X25mm, etc |

Surface treament | original, sanded, brushed |

Color available | 5 regular colors for choice ( IPE, Walnut, gray stone, Cedar, Rosewood) and we can adjust the new color according to the order requirement |

FAQ

We have organized several common questions for our clients,may help you sincerely.

1. How about your company?

Our company is a world class manufacturer & supplier of Wood Plastic Composite and is one of the large-scale professional investment Wood Plastic Composite bases in China. Annually more than 1000 containers of Wood Plastic Composite bases are exported to markets in Europe, North America.

2. How to guarantee the quality of the products?

We can supply certificates, including ISO9001, ISO14001, CE, FSC Certificate, "REACH" Test Reports by SGS; Intertek Test Report by ASTM standard..etc.

3. How to install the WPC decking?

Installation tool: electric saw (desk type or portable),churn drill, electric portable drill and driver

Decking and accessories: 1.decking 2.joist 3.metal clip 4. plastic expansion screws 5.start clip 6.fascia

Installation step:

1. Fix the joist. 2. Decking installation. 3.Fascia installation

- Q:General composite wood floor life

- Three-layer solid wood flooring due to a thicker hardwood surface, can be renovated several times, in order to keep the floor better foot feeling and longer service life, solid wood flooring renovation frequency should not be too high, generally use more than 10 years renovation Better. Maintenance of a better three-tier solid wood composite to the brave raccoon raccoon 侔 shares paralyzed wear Kay board, the service life can be more than 30 years

- Q:Will the composite floor below the bedding treasure 2 cm thick how much per square?

- This price is different in each region, generally in a dozen dollars a square bar

- Q:engineered floor toronto?

- What about it? Engineered wood is available any where flooring is sold. GL

- Q:Because it is a newly renovated house has not moved Dinghu guilty cunning Chong twisted anchor into the floor flooding degree is relatively large, the water leaked 2 days to find the water seepage downstairs walls, paint are blasting Please come after the sale Treatment is to dig out the most serious part of the flooding, the rest do not deal with such water vapor their own volatile I would like to ask those who do not need to replace those soaked in the future will not mold mold, smell out of the problem added: Smell it? Plastic film must have been soaked, is not going to penetrate into the floor inside? More

- Has just dealt with a number of questions on the quality of the floor of the elephant. Out of the question to find Consumers Association corresponders on their fear, Ding Hu Gui guilty cunning attack or even this sentence, buy the floor to go to Beac, Buy multiple layers.

- Q:Woodworking told me that the floor with the bend on the bend, no matter, I put the floor on the ground with the amount of the next, the middle height is 0.4 cm, do not know you decoration of the pro, you buy the floor when there is no injection intoxicated Rescue chewing wedge ax blindly to the floor of the bend more

- Floor plane horizontal bending is not surprising, mainly to see whether the front is a straight line is the lock.

- Q:Our home flooring is multi-storey

- The surface of the parquet is made with a long period of hardwood. But in fact the solid wood composite floor core layer and the bottom of the selection of soft pine or fir criss-cross, generally multi-layer and three points, do not need to play keel. Solid wood flooring itself is sufficient to overcome the surface tension, and feet comfortable. But the solid wood flooring to choose a big brand, such as peace of mind floor. Because of the high technological requirements and the need for strong working capital. In the wet weather of East China, South China and some particularly humid areas, in the installation of solid wood flooring need to shop keel, the floor and the floor should not be too tight between, so as not to wet in the wet season, the expansion of the tide, (floor and floor Between the north and northwest region, the floor between the natural joint is better; should be a professional team to install the installation, solid wood composite floor shop keel installation, in the "who installed, Who is responsible for "the principle. If the installation is not carried out according to the correct laying method, the quality problems caused by the installation team.

- Q:How to clean the composite floor

- Composite floor cleaning method: 1. should immediately clean up the leak. Do not let any liquid stay on the floor for a long time, as they will contaminate the ground and damage protect the wear layer. Absorb excess liquid with a dry cloth or paper towel, do not keep the area moist. 2. After a period of time, the composite floor needs a thorough cleaning. As the water is the most modest cleaning possible. Do it every few months, except for regular sweep or when you notice that a zone is muddy or dirty. 3. If your hardened floor looks dirty and has mud stains, or if it begins to look fade, use a mixture of water and vinegar. Do not use vinegar in its pure form, because it is too corroded. The solution will bring the appearance of the floor luster and the smell of vinegar will disappear in a few minutes. If you hate the smell of a whale, you can add a few drops of lemon, mint or essential oil to the mixture. 4. found to cause chewing gum stains which are very difficult to get rid of, so that ice hardening it, gently scrape off. Be careful not to scratch the floor. Ice can also be used to remove chewing gum from the carpet.

- Q:Will the composite floor out now 240MM wide board, and small board than that kind of good?

- Of course, is a small good in general, the composite board will be a little deformation of what the change ridge rush hoarding hut lut chop but raft after the trough and the mother slot will be listed if the small board, then it will be much better

- Q:Has anyone worked with Bostik EFA for installing an engineered floor? Is EFA better than Bostik Best?

- Bostik Best is the premium adhesive in the wood flooring industry, also the most expensive. You should look at Mapei 980, or Taylor MS Plus adhesives for a lower cost option.

- Q:What are the characteristics of solid wood flooring? How is the price?

- I personally summed up the following seven points: 1) solid wood flooring to retain the solid wood flooring natural texture, foot feeling comfortable features. 2) solid wood flooring and both strengthen the floor wear, easy to install, clean up the characteristics. 3) I solid wood flooring is very suitable for warm home decoration, especially multi-layer parquet. 4) solid wood composite floor hardness than the floor is very small, very suitable for home with the elderly and children decorated family. 5) Solid wood flooring prices between the solid wood flooring and solid wood flooring, is a moderate consumption of water balance, is the majority of the family can accept the scope of consumption. 6) solid wood flooring installation is simple, easy to clean up, no solid wood flooring so delicate. 7) solid wood flooring decoration effect is very good, there are many varieties, such as: solid wood composite antique floor, solid wood fight sprinkle the burning of the hint of Huo Feng Tong Fu wide flower floor. In terms of cost performance, solid wood flooring has a strong geothermal adaptation performance, with a unique pattern, natural color material that is environmentally friendly to the body without harm, in full compliance with national environmental standards.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

2015 Green Choice Outdoor WPC/ wood plastic composite (wpc decking)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords