2015 Full and Semi automatic glass cutting machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Full-automatic Glass Cutting Line

1. Company Information

1.Our company is one of the best professional company, with 12 years history, specialized in manufacturing insulating glass machine, glass cutting machine, pvc & aluminum window and door machine.

2.Since our company founded, "best quality, mutual benefit" is always our principle, offering the best equipment and technical support for the old and new customers.

3.Our products has been exported to many countries, such as Asian countries, European countries, Middle East area ,and South American countries.

Normal machine is properly adjusted before dispatch. You will be able to use the machines immediately.

You will be able to get free training advice towards glass cutting machine in our factory. You will also get free suggestion and consultation,

technical support and service by email/fax/tel and lifetime technical support.

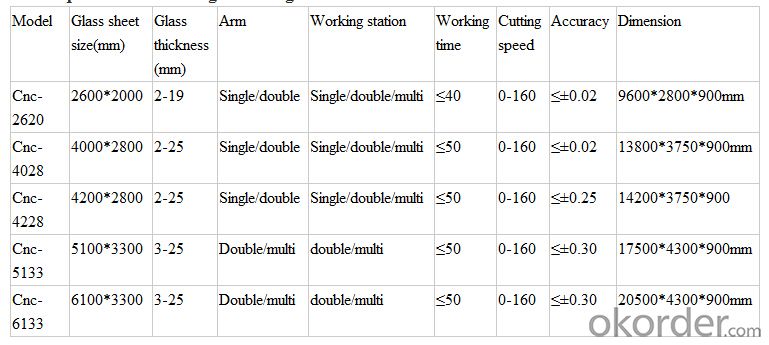

2. Technical parameter:

3. Main components

a, Turning angle: adjustable, from 95 to 98 degree.

b, Rack depth: special connecting rod retractable mechanism, suction cup move forward 150mm, and rack depth is 700mm which could meet different kinds of glass rack.

c, Induction system: two sets of photoelectric sensors to ensure safety operation.

d, Roller bar: special connecting rod retractable mechanism, to ensure the synchronous lift and separate the glass piece safely.

e, Suction system: introduced double layer suction, strong absorption.

f, Suction cup control: Every cup have separated air valve to control, choose the quantity of working cup easily and freely.

g, Lift and loading system: lift glass before loading in case the glass damaged because of sticking.

h, Alarm system: The machine has the alarm fittings, it have self inspection system and red and green alarm button.

i, Operation mode: The machine has two kinds controlling mode(automation and manual)

j, Operation screen: Color LCD screen interface

k, Parameter setting: The order and glass quantity of loading can be set automatically with digital information.

4. Main Introduction: Automatic glass loading machine

With very sturdy frame structure, reliable vacuum system design with venturi vacuum device to prevent glass falling in case of electricity blackouts. Loading arms was driven by electrical motor.

High quality certified components to guarantee long term reliability and easy, spare parts availability.

Modular design makes future upgrades to more stations available.

Glass cutting line applies to: Building glass, insulated doors and windows, low-e glass, automobile glass, household appliance glass, furniture glass, solar energy glass, cook glass, mirrors, artwork glass and so forth.

5.Technical description

1) Turning mode: mechanical turning, fast speed, steady operation, loading glass thickness 3 to 19 mm. Assembled with double line turning transmission chain, to ensure the transmission process safety and reliable.

2) Turning angle: adjustable, from 95 to 98 degree.

3) Rack depth: special connecting rod retractable mechanism, suction cup move forward 150mm, and rack depth is 700mm which could meet different kinds of glass rack.

4) Induction system: two sets of photoelectric sensors to ensure safety operation.

5) Roller bar: special connecting rod retractable mechanism, to ensure the synchronous lift and separate the glass piece safely.

6) Suction system: introduced double layer suction, strong absorption.

7) Suction cup control: Every cup have separated air valve to control, choose the quantity of working cup easily and freely.

8) Lift and loading system: lift glass before loading in case the glass damaged because of sticking.

9) Alarm system: The machine has the alarm fittings, it have self inspection system and red and green alarm button.

10) Operation mode: The machine has two kinds controlling mode(automation and manual)

11) Operation screen: Color LCD touch screen interface.

12) Parameter setting: The order and glass quantity of loading can be set automatically with digital information.

6. FAQ

Q1. Can we design packaging?

Yes, but there is with quantity limitation. For 10,000 pcs, we will make the packing free for the client, and if less than 10,000 pcs, we can talk, the package is free or little money will be charged.

Q2. Can we add our logo on products?

Yes, there are several ways to do this. We can put the label of your logo on the products or make the silk print of your logo on the products. It is free.

Q3. Can we customize product?

OEM and ODM are welcomed from Anern. We have rich experiences in this area.

- Q:How do you strengthen the glass and use the equipment?

- Ordinary annealed glass first cut into required size, and then heated to the softening point of 700 degrees, then rapid and uniform cooling of the glass (usually 5-6MM at 700 degrees high temperature heating about 240 seconds, 150 seconds of cooling. 8-10MM glass heating at 700 degrees high temperature for about 500 seconds, cooling about 300 seconds. In short, depending on the thickness of the glass, the choice of heating and cooling time is also different. After tempering, uniform compressive stress is formed on the glass surface, while tensile stress is formed inside the glass to improve the bending and impact strength of the glass. The strength of the glass is about four times higher than that of the ordinary annealed glass. Have good tempered glass, can no longer be any cutting, grinding or damaged, otherwise it will damage due to uniform compressive stress balance and smashed to pieces".

- Q:I'd like to open an art glass processing factory. What equipment do I need?

- Find a glass art processing factory to work for a period of time, process and equipment do not know, the enemy can ever victorious, I also want to do glass processing technology, but no money, can only think of.

- Q:How is glass produced? How much does it cost to open a glass plant and what equipment do we need?

- What kind of glass factory do you prefer? A toughened glass factory, an ordinary glass factory and so on. The investment in the toughened glass factory is much lower than that of the ordinary glass factory

- Q:Does anyone know where there are machines for making single, double layer glass by hand?

- The glass edge grinding machine has the advantages of simple structure and bilateral advanced, active edge by connecting group type supporting structure, glass transmission adopts the upper type transmission shaft, high precision glass two times the original positioning technology, using PLC control, man-machine interface system developed is simple and convenient, with a full set of stainless steel tank, high speed milling and good effect, stable performance, excellent quality, maintenance or equipment failure caused by the shutdown of the possibility is very small

- Q:How much money do you need to invest in making glass hot bending? What equipment should I buy?

- Buy finished five to hundreds of thousands of glass grinding machine and cleaning machine around sixty thousand yuan, if the initial investment of one hundred thousand yuan or so, do not count the current funds

- Q:Toughened glass production equipment and price

- Then you have to pay back money, inventory, rent, utilities, wages, etc.. If these are entirely new investments, about 250-300.

- Q:Can individuals do quartz glass processing? What kind of equipment do you have? How much does it cost? Is there a high demand for technical content?

- You want what processing technology content for the two bombs and one satellite, it fairly simple!The demand depends on your quality.Funds, equipment and funds are few, but more money.

- Q:Can glass fiber reinforced plastics be machined with high precision?

- Matters needing attention(1) because the mechanical properties of glass fiber products are brittle and brittle, it is difficult to clamp. The clamping force causes the workpiece to deform or block the workpiece, and the excessive force will cause the workpiece to fly off.(2) because of the glass fiber heat is relatively poor, linear expansion into relatively large, the workpiece is easy to deform, the size is more difficult to control.(3) the best data can be obtained only through process experiments.

- Q:Can organic glass be processed two times?

- Two organic glass molding and precision cutting, according to design drawings, plates, cutting, carving, drilling, milling, polishing, bending, adhesive, hot pressing, printing, sandblasting, coating and other processing, maintained at a certain angle and shape, to meet customer requirements.

- Q:How is the inorganic fiberglass ventilating pipe produced? Is it produced by hand or by mechanical production? What equipment do you need?

- Many of the FRP products are produced by hand. As long as there are moulds, they can be produced

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

2015 Full and Semi automatic glass cutting machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products